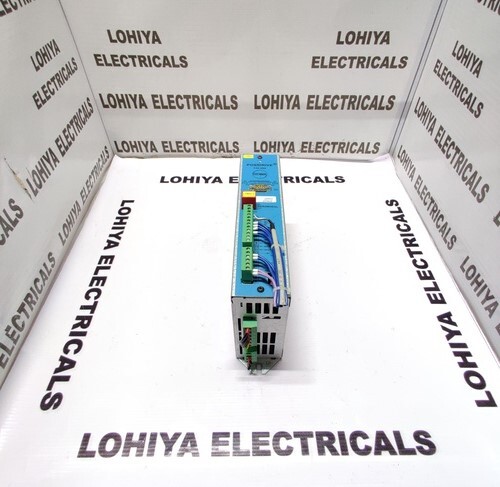

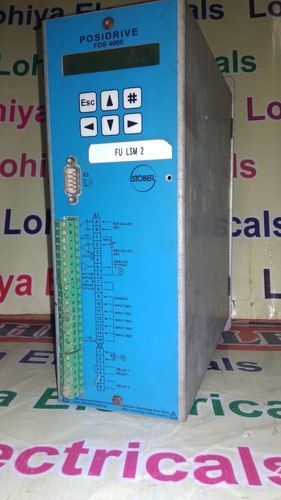

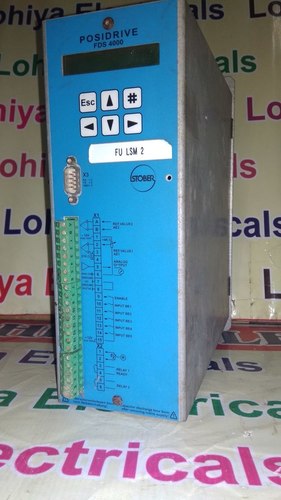

STOBER POSI DRIVE

STOBER POSI DRIVE Specification

- Current Range

- Up to 80 A

- Phase

- 3 Phase

- Output Type

- Shaft Output

- Rated Power

- Varies by model

- Noise Level

- Less than 75 dB

- Operating Temperature

- -10C to +55C

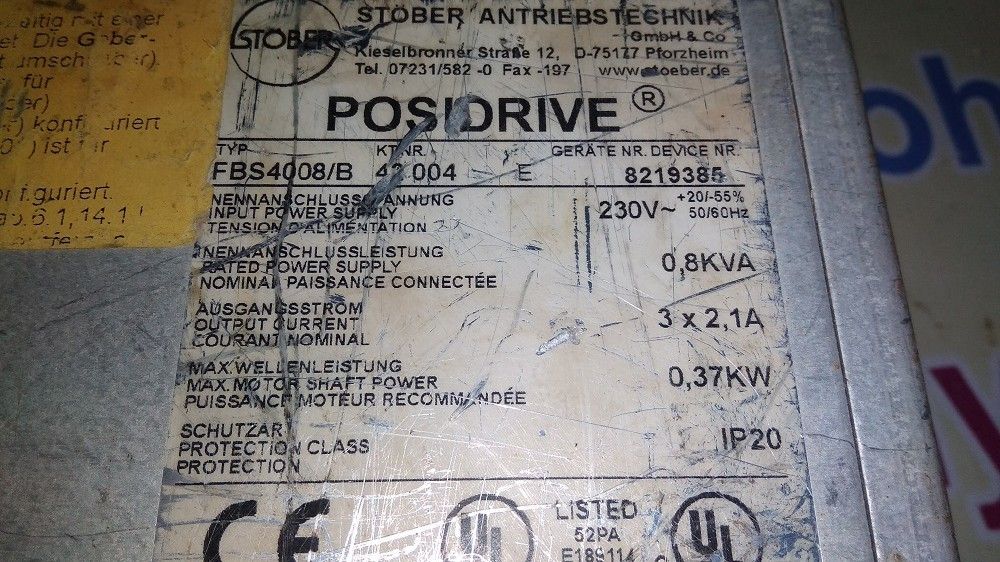

- Output Current

- Up to 80 A

- Power Factor

- > 0.95

- Rated Current

- Varies by model

- Cooling Method

- Natural Air Cooled / Forced Cooling

- Connector Type

- Standard Industrial Connectors

- Application

- Conveyors, Packaging, Material Handling, Automation

- Features

- Compact Design, High Torque, Maintenance Free, Precise Positioning

- Power Supply

- AC

- Working Temperature

- -10C to +55C

- Product Type

- POSI DRIVE

- Output Power

- 0.12 kW 45 kW

- Output Frequency

- 50/60 Hz

- Input Voltage

- 230 V / 400 V AC

- Voltage Protection

- Overvoltage and Undervoltage Protection

- Efficiency

- Up to 96%

- Material

- High-Grade Alloy Steel

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- 8 kg 120 kg

- Thermal Protection

- Integrated thermal protection

- Positioning Accuracy

- High precision, low backlash gearset

- Speed Range

- 10 600 rpm

- Remote Control Support

- Available as an option

- Shaft Diameter

- 25 mm to 60 mm

- Gear Ratio

- Up to 120:1

- Color

- Blue

- Torque Range

- 10 Nm to 1000 Nm

- Lubrication

- Lifetime lubricated

- Vibration

- Designed for low vibration

- Mounting Type

- Flange or foot mounting

- Protection Class

- IP65

About STOBER POSI DRIVE

STOBER POSI DRIVE: The Competitive Edge for Modern Plants

STOBER POSI DRIVE stands apart for its competitive advantages, including high torque, sizzling efficiency, and lifetime lubrication for maintenance-free reliability. Designed for conveyors, packaging, and material handling, its valiant performance ensures optimal workflow in automated and commercial environments. Peerless positioning accuracy and low vibrations deliver seamless, precise motion for advanced processing plants. Harness the incomparable blend of robust durability and select customizability, making STOBER POSI DRIVE the ephemeral choice for forward-thinking enterprises.

Packaging, Price, and Shipping: STOBER POSI DRIVE Details

Each STOBER POSI DRIVE is securely packaged to ensure product integrity during transit. Our list price includes standard industrial connectors and comprehensive protection features, with charges for additional customization options as needed. Sample policy allows evaluation, with samples available on request for a nominal charge. FOB port arrangements are efficiently managed for swift worldwide dispatch. Rely on our transparent pricing and safe packaging solutions to receive your order in peerless condition, ready for installation.

FAQs of STOBER POSI DRIVE:

Q: How does the STOBER POSI DRIVE ensure precise positioning in automation applications?

A: The STOBER POSI DRIVE is engineered with a high-precision, low-backlash gearset, enabling accurate positioning critical for automation, material handling, and packaging processes.Q: What mounting options are available for the STOBER POSI DRIVE?

A: This drive offers select mounting choiceseither flange mounting or foot mountingproviding versatile installation options for a wide range of commercial and industrial setups.Q: When is remote control support available for the STOBER POSI DRIVE?

A: Remote control support is offered as an optional feature, which can be included based on your specific plant requirements and operational preferences.Q: Where can the STOBER POSI DRIVE be installed in industrial settings?

A: With its robust protection (IP65 rated) and adaptable mounting, the STOBER POSI DRIVE is ideal for conveyors, packaging lines, and material handling systems in automation-driven industrial plants.Q: What are the key benefits of the drives integrated thermal and voltage protection features?

A: Integrated thermal protection and both overvoltage and undervoltage safeguards preserve the drives integrity, reduce downtime, and ensure safe, valiant performance even under demanding operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STOBER POSI DRIVE Category

STOBER FAS4014 POSIDRIVE

Line Regulation : 1%

Connector Type : Screw terminals

Application : Industrial automation, conveyor systems, machinery drive

Power Supply : AC 400480V, 50/60 Hz

Features : Compact design, high overload capability, integrated brake chopper, userfriendly interfaces

Material : Integrated electronics with metal housing

STOBER SERVO DRIVE

Line Regulation : 0.5%

Connector Type : Screw Terminal, Plugin Connector

Application : Automation, Robotics, CNC Machines

Power Supply : AC Mains

Features : Compact Design, High Reliability, Precise Control

Material : Industrial Grade Alloy

STOBER SERVO DRIVE

Line Regulation : <0.5%

Connector Type : Screw Terminal, Plugin Connectors

Application : Industrial Automation, CNC Machines, Robotics

Power Supply : 3 x 400V AC

Features : Compact Design, Precise Speed Control, Integrated Safety Functions, Digital Display

Material : Aluminum Alloy Housing

STOBER SERVO DRIVE

Line Regulation : 0.5%

Connector Type : Screw Terminal

Application : Industrial Automation, Robotics, CNC Machines

Power Supply : AC Power

Features : Compact Design, High Dynamic Response, Integrated Safety Functions

Material : Industrial Grade Metal Housing

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry