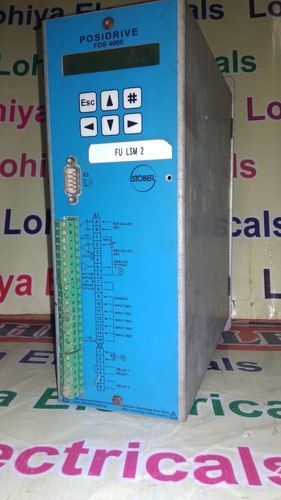

STOBER SERVO DRIVE

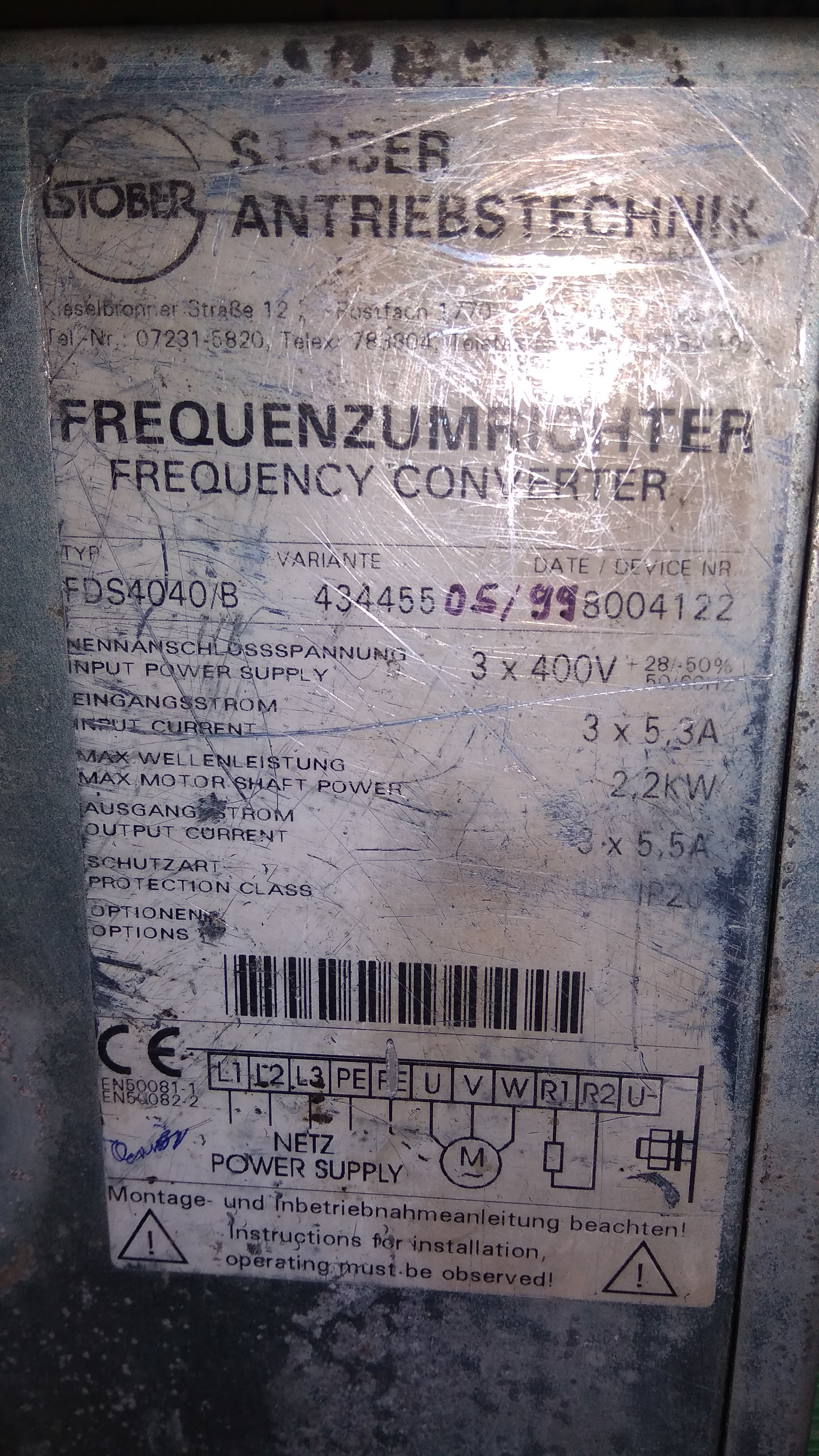

STOBER SERVO DRIVE Specification

- Working Temperature

- -10C to +55C

- Application

- Automation, Robotics, CNC Machines

- Power Supply

- AC Mains

- Power Factor

- >0.98

- Cooling Method

- Forced Air Cooling

- Connector Type

- Screw Terminal, Plug-in Connector

- Output Type

- Digital & Analog

- Noise Level

- <50 dB

- Operating Temperature

- -10C to +55C

- Phase

- Three Phase

- Output Current

- Up to 4.5 A

- Rated Power

- 750 W

- Rated Current

- 3.5 A

- Current Range

- 0-4.5 A

- Features

- Compact Design, High Reliability, Precise Control

- Product Type

- Servo Drive

- Output Power

- 750 W

- Output Frequency

- 0-400 Hz

- Input Voltage

- 220-240 V AC

- Voltage Protection

- Over-voltage, Under-voltage Protection

- Efficiency

- >95%

- Material

- Industrial Grade Alloy

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to +85C

- Weight

- 3.5 kg

- Programming Software

- STOBER DriveControl Suite

- Firmware Upgrade

- Supported via USB

- Display Type

- LCD/LED status indicators

- Pulse Input

- Supported

- Control Modes

- Position, Speed, Torque Control

- Encoder Feedback

- Absolute/Incremental encoders

- Ambient Humidity

- <95% non-condensing

- Cooling Airflow

- Forced

- Communication Interfaces

- EtherCAT, CANopen, PROFIBUS, Modbus

- Protection Class

- IP20/IP54

- Safety Functions

- Safe Torque Off (STO), Short-circuit Protection

- Mounting Type

- Panel Mount

About STOBER SERVO DRIVE

Competitive Edge & Versatile Applications of STOBER SERVO DRIVE

Experience the competitive advantage of the STOBER SERVO DRIVEcharacterized by its compact design, high reliability, and precise control. This drive excels in industrial automation, robotics, and CNC machinery, performing admirably even in demanding environments. Its application surface extends to manufacturing floors, assembly lines, and robotic arms, ensuring efficient and faultless operation. The forced air cooling and advanced protection features contribute to its superior performance in varied industrial settings.

Certifications, Delivery Lead Time, and Sample Policy: STOBER SERVO DRIVE

The STOBER SERVO DRIVE upholds global industry certifications, reflecting its adherence to rigorous standards for performance and safety. Delivery time typically varies based on the proposal amount and order rate, with prompt dispatch for standard list price orders. Sample policies are tailored to business needs, offering opportunities for evaluation before bulk commitments. Each drive is carefully packaged and shipped to ensure quality arrives intact at your facility.

FAQs of STOBER SERVO DRIVE:

Q: How does the STOBER SERVO DRIVE enhance automation processes?

A: The drive supports precise position, speed, and torque control, facilitating high-accuracy automation, robotics, and CNC operations while ensuring reliable and safe motor performance in demanding settings.Q: What communication interfaces are available for integrating the STOBER SERVO DRIVE?

A: The drive is equipped with EtherCAT, CANopen, PROFIBUS, and Modbus interfaces, allowing seamless connectivity with a variety of industrial networks and controllers.Q: When is delivery typically promised after placing an order in India?

A: Delivery time depends on the proposal amount and order rate, with most standard orders shipped promptly. Further lead time details can be provided at the time of quotation.Q: Where can the STOBER SERVO DRIVE be applied?

A: It is ideal for automation sectors, including robotics arms, CNC machines, and manufacturing lines, where precise control and robust performance are required.Q: What is the process for firmware upgrades on this drive?

A: Firmware upgrades are supported via USB, enabling users to keep their drive updated easily with the latest features and safety enhancements.Q: How does the drive ensure safety and equipment protection?

A: Safety functions include Safe Torque Off (STO), short-circuit protection, and comprehensive voltage controls, preventing damage to equipment and enhancing operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STOBER POSI DRIVE Category

STOBER FAS4014 POSIDRIVE

Power Factor : >=0.95

Voltage Protection : Overvoltage, undervoltage, shortcircuit

Cooling Method : Integrated fan cooling

Output Type : Other, Three Phase AC

Connector Type : Screw terminals

Working Temperature : 10C to +50C

STOBER POSI DRIVE

Power Factor : > 0.95

Voltage Protection : Overvoltage and Undervoltage Protection

Cooling Method : Natural Air Cooled / Forced Cooling

Output Type : Other, Shaft Output

Connector Type : Standard Industrial Connectors

Working Temperature : 10C to +55C

STOBER SERVO DRIVE

Power Factor : >0.9

Voltage Protection : Overvoltage, Undervoltage, Short Circuit Protection

Cooling Method : Forced Air Cooling

Output Type : Other, Threephase

Connector Type : Screw Terminal, Plugin Connectors

Working Temperature : 0C to +55C

STOBER POSI DRIVE

Power Factor : >0.95

Voltage Protection : Overvoltage and Undervoltage Protection

Cooling Method : Natural Air Cooling

Output Type : Other, Shaft Output

Connector Type : Terminal Box

Working Temperature : 10C to +40C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry