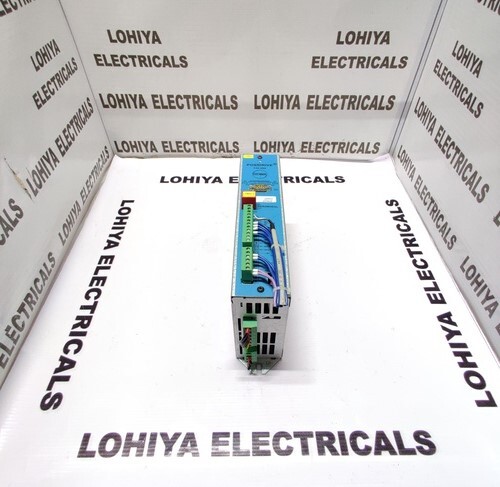

STOBER SERVO DRIVE

STOBER SERVO DRIVE Specification

- Working Temperature

- 0C to +55C

- Output Type

- Three-phase

- Output Current

- 12 A

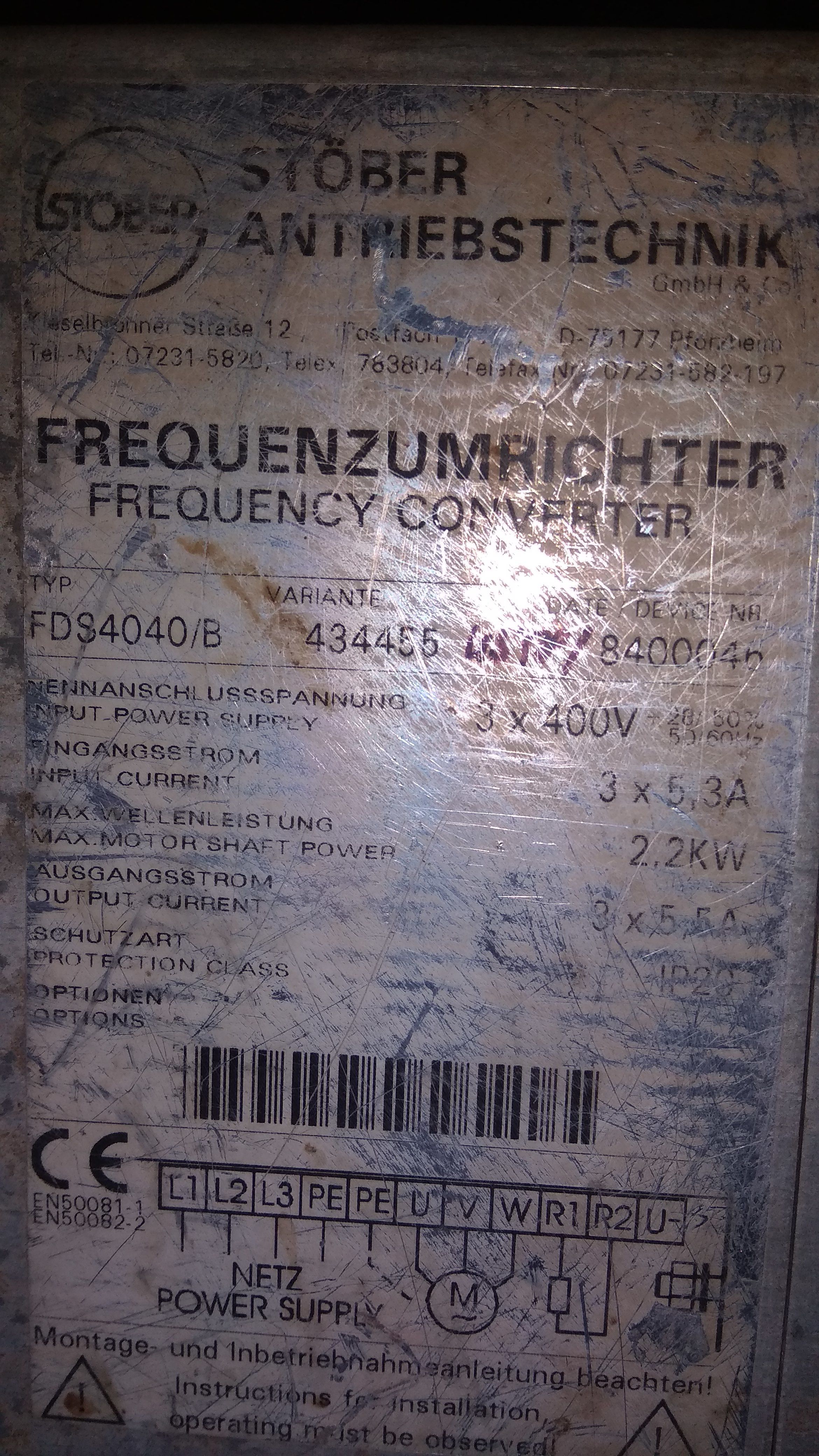

- Phase

- Three Phase

- Application

- Industrial Automation, CNC Machines, Robotics

- Features

- Compact Design, Precise Speed Control, Integrated Safety Functions, Digital Display

- Power Supply

- 3 x 400V AC

- Operating Temperature

- 0C to +55C

- Current Range

- 0 - 15 A

- Rated Power

- 5 kW

- Power Factor

- >0.9

- Rated Current

- 12 A

- Cooling Method

- Forced Air Cooling

- Noise Level

- <58 dB

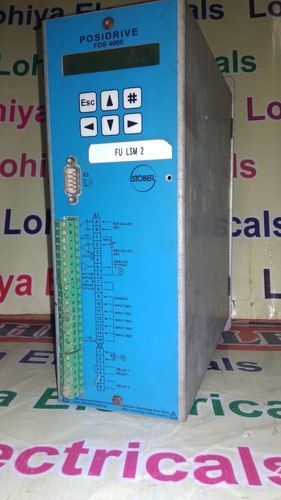

- Connector Type

- Screw Terminal, Plug-in Connectors

- Product Type

- Servo Drive

- Output Power

- 5 kW

- Output Frequency

- 0 - 600 Hz

- Input Voltage

- 3 x 400V AC

- Voltage Protection

- Overvoltage, Undervoltage, Short Circuit Protection

- Efficiency

- Up to 96%

- Material

- Aluminum Alloy Housing

- Line Regulation

- <0.5%

- Storage Temperature

- -25C to +70C

- Weight

- 4.8 kg

- Degree of Protection

- IP20

- Ambient Humidity

- 5% - 95% (non-condensing)

- Encoder Support

- Supported (Incremental/Absolute)

- Control Method

- Field Oriented Control (FOC), Vector Control, Position, Velocity and Torque Control

- Communication Interface

- Ethernet, CANopen, Modbus, EtherCAT

- Braking Resistor

- Optional External

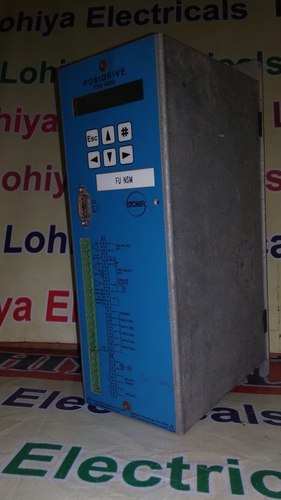

- Display

- LCD Display with LED Status Indicators

- Digital Inputs/Outputs

- 8 DI / 4 DO

- Start-up Time

- <1 Second

- Mounting Type

- Panel Mount, Wall Mount

- Firmware Update

- Supported via USB/Network

- Analog Inputs/Outputs

- 2 AI / 2 AO

About STOBER SERVO DRIVE

Discover the new release of the STOBER SERVO DRIVE-a sterling choice for industrial automation, CNC machines, and robotics. This top-notch drive boasts Field Oriented Control (FOC), Vector Control, and precise Position, Velocity, and Torque Control. Highly recommended for its support of Ethernet, CANopen, Modbus, and EtherCAT, it ensures excellent connectivity. Features include an aluminum alloy housing, LCD display, and integrated safety, all in a compact design. With 5 kW output, rapid <1 second start-up, and 96% efficiency, this drive is built for superior performance.

Versatile Application & User Guidance

The STOBER SERVO DRIVE is suitable for use across multiple demanding sectors, including industrial automation, CNC machines, and robotics. Ideal for precise and dynamic operations, it accommodates both panel and wall mounting. To operate, follow the provided guidelines for installation, utilize the intuitive LCD display for programming, and select operational modes as required. Designed for continuous, intensive use, this drive delivers consistent output, enhancing both productivity and control in automated environments.

Delivery, Packaging, and Export Markets

Delivery time for the STOBER SERVO DRIVE depends on order quantity and destination, with prompt dispatch assured. Each unit is securely packaged with protective materials to ensure safe transportation. Our handover process includes a thorough quality check and shipment tracking. The drive is ready for global markets, with main export destinations spanning Europe, Asia, and beyond. This focus on care in packaging and efficient handover helps guarantee customer satisfaction with every delivery.

Versatile Application & User Guidance

The STOBER SERVO DRIVE is suitable for use across multiple demanding sectors, including industrial automation, CNC machines, and robotics. Ideal for precise and dynamic operations, it accommodates both panel and wall mounting. To operate, follow the provided guidelines for installation, utilize the intuitive LCD display for programming, and select operational modes as required. Designed for continuous, intensive use, this drive delivers consistent output, enhancing both productivity and control in automated environments.

Delivery, Packaging, and Export Markets

Delivery time for the STOBER SERVO DRIVE depends on order quantity and destination, with prompt dispatch assured. Each unit is securely packaged with protective materials to ensure safe transportation. Our handover process includes a thorough quality check and shipment tracking. The drive is ready for global markets, with main export destinations spanning Europe, Asia, and beyond. This focus on care in packaging and efficient handover helps guarantee customer satisfaction with every delivery.

FAQ's of STOBER SERVO DRIVE:

Q: How can I update the firmware of the STOBER SERVO DRIVE?

A: Firmware updates are easily performed via USB or network connection, ensuring the drive always runs on the latest software for top performance.Q: What communication protocols are supported by the STOBER SERVO DRIVE?

A: The drive supports Ethernet, CANopen, Modbus, and EtherCAT communication interfaces, enabling flexible integration with a variety of industrial systems.Q: What are the recommended applications for this servo drive?

A: It is highly recommended for industrial automation, CNC machinery, and robotics, where precise motion control and reliability are essential.Q: Where can I mount the STOBER SERVO DRIVE?

A: This model supports versatile installation, allowing for both panel mounting and wall mounting depending on your system requirements.Q: What safety features does the servo drive offer?

A: The STOBER SERVO DRIVE includes integrated safety functions, voltage protections (overvoltage, undervoltage, short circuit), and a robust design for reliable operation.Q: What is the process for installing and starting up the drive?

A: Installation involves securing the drive using screw terminal or plug-in connectors, configuring via the LCD display, and starting up, which takes less than a second.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in STOBER POSI DRIVE Category

STOBER FAS4014 POSIDRIVE

Line Regulation : 1%

Output Frequency : 0500 Hz

Current Range : 1.0 to 9.0 A

Rated Power : Up to 4.0 kW

Output Power : 0.37 kW to 4.0 kW

Rated Current : Up to 9.0 A

STOBER SERVO DRIVE

Line Regulation : 0.5%

Output Frequency : 0400 Hz

Current Range : 04.5 A

Rated Power : 750 W

Output Power : 750 W

Rated Current : 3.5 A

STOBER POSI DRIVE

Line Regulation : 1%

Output Frequency : 50/60 Hz

Current Range : Up to 80 A

Rated Power : Varies by model

Output Power : 0.12 kW 45 kW

Rated Current : Varies by model

STOBER SERVO DRIVE

Line Regulation : 0.5%

Output Frequency : 0400 Hz

Current Range : 0.53.0 A

Rated Power : 750 W

Output Power : 0.75 kW

Rated Current : 2.2 A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry