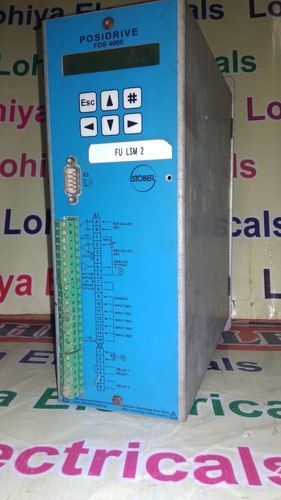

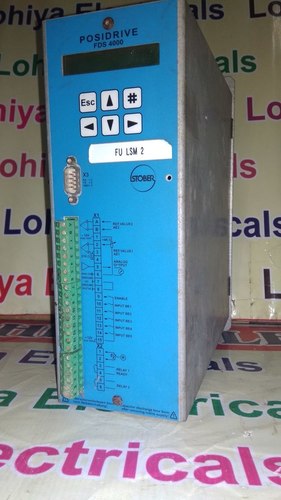

STOBER SERVO DRIVE

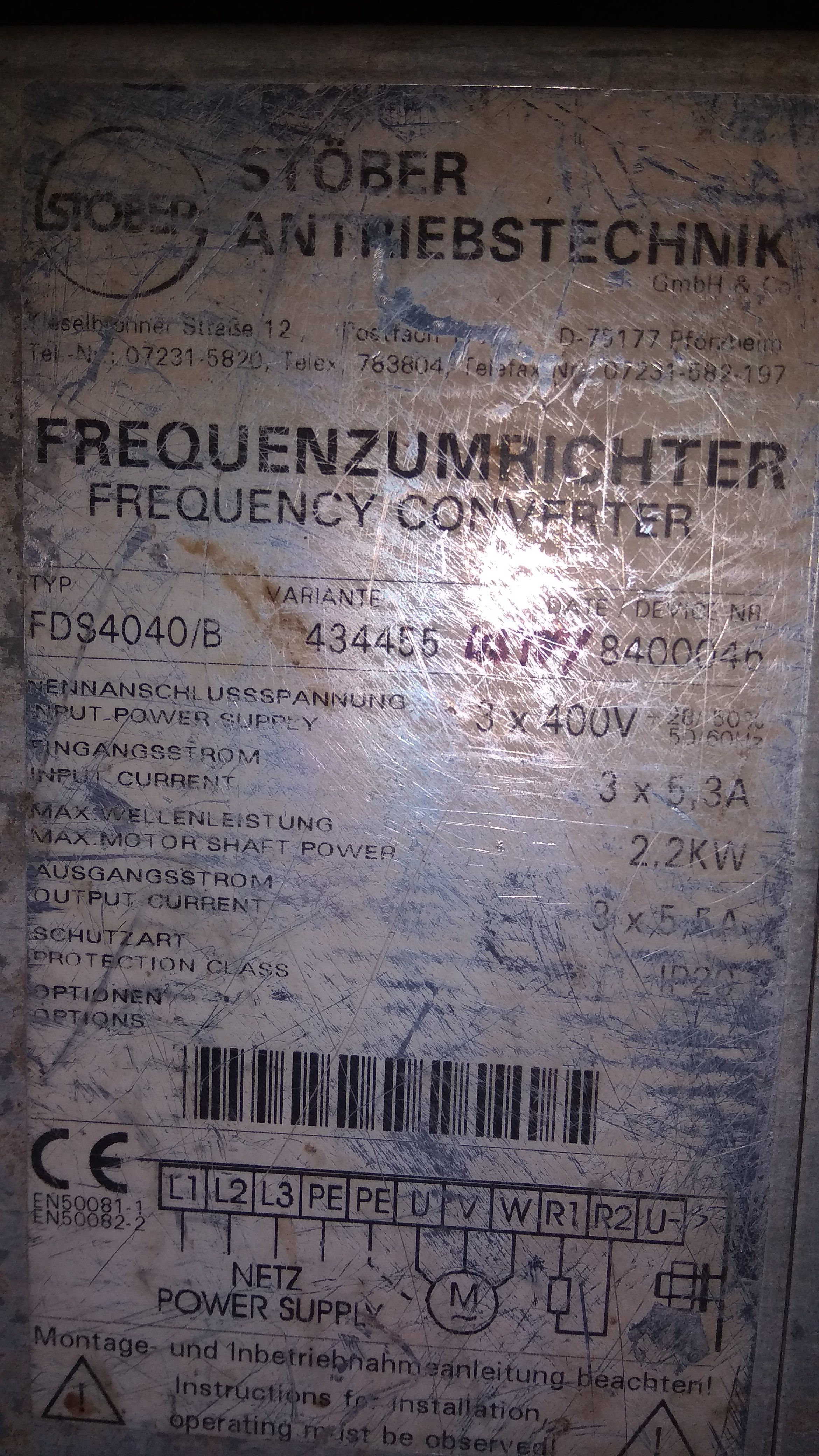

STOBER SERVO DRIVE Specification

- Power Supply

- AC Power

- Connector Type

- Screw Terminal

- Features

- Compact Design, High Dynamic Response, Integrated Safety Functions

- Phase

- Three Phase

- Power Factor

- >0.98

- Application

- Industrial Automation, Robotics, CNC Machines

- Output Type

- Digital / Analog

- Operating Temperature

- 0C to 40C

- Rated Current

- 3.3 A

- Cooling Method

- Forced Air Cooling

- Noise Level

- <55 dB

- Output Current

- Up to 3.3 A

- Current Range

- 0.5 A to 3.3 A

- Working Temperature

- 0C to 40C

- Rated Power

- 1.1 kW

- Product Type

- Servo Drive

- Output Power

- 1.1 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 380-480 V AC

- Voltage Protection

- Overvoltage and Undervoltage Protection

- Efficiency

- 95%

- Material

- Industrial Grade Metal Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- 2.5 kg

- Mounting Type

- Panel Mount

- Protection Class

- IP20

- Overload Capacity

- 150% of Rated Current for 60 sec

- Digital Inputs/Outputs

- 8 DI / 4 DO

- Analog Inputs/Outputs

- 2 AI / 2 AO

- Control Mode

- Position, Velocity, and Torque Control

- Braking Function

- Integrated Dynamic Braking Unit

- Input Frequency

- 50/60 Hz

- Display Type

- LED Status Indicators

- Communication Interface

- RS485 / CANopen / EtherCAT

- Motor Compatibility

- Synchronous and Asynchronous Servo Motors

About STOBER SERVO DRIVE

STOBER SERVO DRIVE Features and Applications

The STOBER SERVO DRIVE offers a compact design with high dynamic response, integrated safety features, and reliable forced air cooling. With advanced control modes for position, velocity, and torque, it excels in industrial automation, robotics, and CNC machine operations. Its compatibility with both synchronous and asynchronous servo motors makes it an adaptable choice for various applications, ensuring precise and stable performance across complex industrial environments.

Premium Domestic Market Reach and Packaging Details

The STOBER SERVO DRIVE is tailored for premium domestic and export markets, meeting demanding industrial standards with valued certifications. Each drive is securely packaged for safe transit and straightforward installation. Quotations are provided on request to suit individual customer specifications, with a focus on dependable service. Comprehensive certifications and adherence to superior quality control protocols ensure reliability and trust for every client, whether for industrial procurement or distribution.

FAQs of STOBER SERVO DRIVE:

Q: How does the STOBER SERVO DRIVE improve automation processes?

A: The STOBER SERVO DRIVE enhances automation by offering advanced position, velocity, and torque control, ensuring precise operations in robotics, CNC machines, and industrial automation setups.Q: What protection features are integrated into the STOBER SERVO DRIVE?

A: This servo drive features overvoltage and undervoltage protection, integrated dynamic braking, and an IP20-rated industrial-grade metal housing, offering reliable and safe operation in tough environments.Q: Where can the STOBER SERVO DRIVE be successfully used?

A: The drive is ideal for applications in industrial automation, robotics, and CNC machinery, thanks to its broad motor compatibility and dynamic control capabilities.Q: What is the process for obtaining a quotation for the STOBER SERVO DRIVE?

A: You may contact the supplier or trader directly with your application requirements. Detailed quotations are prepared to suit individual project needs, with export and domestic packaging options available.Q: What benefits do the status LED indicators provide on this servo drive?

A: LED status indicators allow for rapid diagnostics and real-time monitoring of the drives operational state, reducing downtime and streamlining maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STOBER POSI DRIVE Category

STOBER FAS4014 POSIDRIVE

Power Supply : AC 400480V, 50/60 Hz

Connector Type : Screw terminals

Voltage Protection : Overvoltage, undervoltage, shortcircuit

Phase : Other, Threephase

Features : Compact design, high overload capability, integrated brake chopper, userfriendly interfaces

Power Factor : >=0.95

STOBER SERVO DRIVE

Power Supply : AC Mains

Connector Type : Screw Terminal, Plugin Connector

Voltage Protection : Overvoltage, Undervoltage Protection

Phase : Three Phase

Features : Compact Design, High Reliability, Precise Control

Power Factor : >0.98

STOBER SERVO DRIVE

Power Supply : 3 x 400V AC

Connector Type : Screw Terminal, Plugin Connectors

Voltage Protection : Overvoltage, Undervoltage, Short Circuit Protection

Phase : Three Phase

Features : Compact Design, Precise Speed Control, Integrated Safety Functions, Digital Display

Power Factor : >0.9

STOBER POSI DRIVE

Power Supply : AC Power Supply

Connector Type : Terminal Box

Voltage Protection : Overvoltage and Undervoltage Protection

Phase : Three Phase

Features : Maintenance Free, Robust Construction, Precise Positioning, High Reliability

Power Factor : >0.95

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry