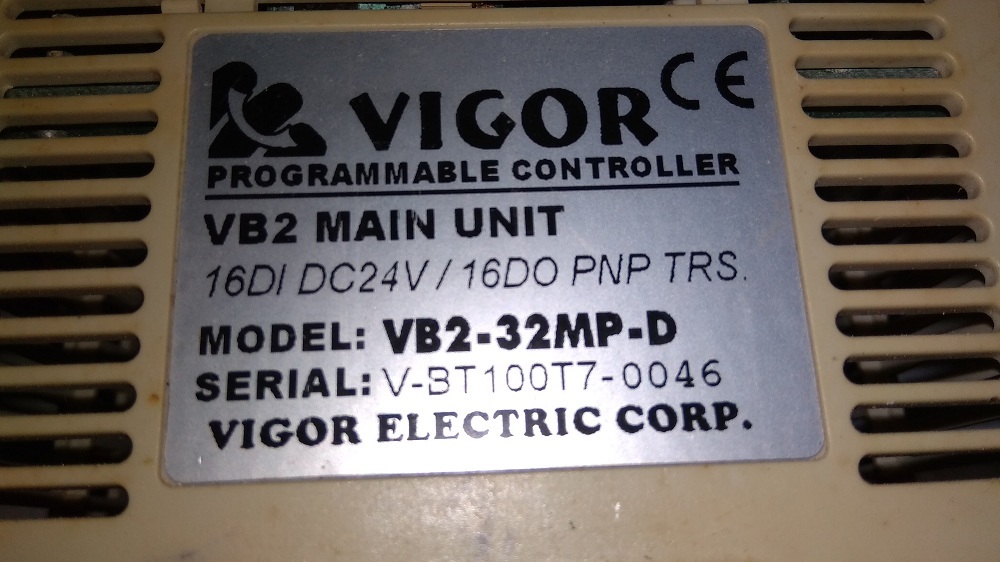

VIGOR PLC

VIGOR PLC Specification

- Installation Type

- DIN Rail Mounting

- Phase

- Single/Three phase compatible (model dependent)

- Frequency

- 50/60 Hz

- Output

- Relay/Transistor (varies by model)

- Features

- Modular Design, Expandable I/O, High-Speed Processing, Built-in Communication Interfaces

- Connectivity Type

- RS232/RS485/USB/Ethernet (model dependent)

- Current

- Max. 2A relay output, 0.5A transistor output

- Protection Level

- Overvoltage and Electronic Protection

- IP Rating

- IP20

- Mounting Type

- DIN rail

- Display

- LED Indicator

- Usage & Applications

- Factory Automation, Process Line Control, Packaging Machinery

- Product Type

- Programmable Logic Controller (PLC)

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0C to 55C

- Input

- Digital/Analog Inputs (varies by model)

- Application

- Industrial automation, process control, machine control

- Supply Voltage

- 24V DC / 220V AC (depending on model)

- Accuracy

- High control accuracy (up to microsecond response, application dependent)

- Dimension (L*W*H)

- Varies by model (typical: 125 x 90 x 60 mm)

- Weight

- Approx. 350g

- Number of I/O Points

- Vary by model (e.g., 8/16/32 points)

- Communication Protocols Supported

- Modbus, TCP/IP, RTU

- Memory Capacity

- Program Memory up to 16k steps

- Programming Language

- Ladder Logic, Instruction List (IL)

About VIGOR PLC

Specific Usage and Advanced Application

VIGOR PLC is crafted for demanding applications such as factory automation, process control, and packaging machinery. Its modular design enables seamless expansion with digital and analog inputs, making it adaptable for diverse plant operations. Advanced features like high-speed processing and built-in communication interfaces ensure high control accuracy. Ideal for process line control and machine automation, it can be installed on DIN rails and is protected with overvoltage and electronic safeguards for reliable, efficient functioning.

Supply Ability, Payment Terms, and Export Markets

VIGOR PLC boasts premium supply ability, ensuring prompt order processing and secure shipping to customers worldwide. Flexible payment terms are available to make procurement hassle-free. Serving main export markets across Asia, Europe, and the Americas, the product is provided by leading suppliers and traders. With robust packaging and attentive service, buyers are guaranteed priority handling and delivery, making it the preferred choice for complex industrial requirements.

FAQs of VIGOR PLC:

Q: How does the VIGOR PLC contribute to improved process control accuracy?

A: VIGOR PLC utilizes high-speed processing, advanced modular design, and microsecond response times to deliver exceptional control accuracy for demanding industrial and process control applications.Q: What programming languages are compatible with VIGOR PLC?

A: You can program VIGOR PLC using Ladder Logic or Instruction List (IL), providing flexibility for different engineering requirements and user expertise.Q: Where can the VIGOR PLC be installed within a plant?

A: VIGOR PLC is easily mounted on DIN rails, making it suitable for installation in control panels, machinery enclosures, and plant process stations.Q: Which communication protocols does VIGOR PLC support for network integration?

A: VIGOR PLC supports Modbus (TCP/IP, RTU), RS232, RS485, USB, and Ethernet, enabling seamless connectivity with other industrial devices and central control systems.Q: What benefits does modular I/O expansion offer for users?

A: Modular I/O expansion allows users to tailor input and output configurations according to the unique needs of their process, enhancing flexibility and scalability for various industrial setups.Q: When is product delivery typically processed, and is shipping secure?

A: Order processing is prompt, and shipping is conducted securely through premium channels, ensuring timely and protected delivery to domestic and international destinations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VIGOR MODULE CPU PLC Category

VIGOR PLC

Supply Voltage : 24V DC / 220V AC (model dependent)

IP Rating : IP20

Current : 0.5A (typical)

Protection Level : Other, Surge and Overvoltage Protection Builtin

Product Type : Programmable Logic Controller (PLC)

Frequency : 50/60Hz

VIGOR PLC

Supply Voltage : AC100240V; Optional DC24V

IP Rating : IP20

Current : Max 2A per output (Relay), Max 0.75A per output (Transistor)

Protection Level : Other, Short circuit and overload protection

Product Type : Programmable Logic Controller (PLC)

Frequency : 50/60 Hz

VIGOR POWER MODULE

Supply Voltage : AC 220V

IP Rating : IP20

Current : 10A

Protection Level : Other, Overload/Short Circuit

Product Type : Power Module

Frequency : 50/60Hz

VIGOR PLC

Supply Voltage : 24V DC

IP Rating : IP20

Current : 600 mA

Protection Level : Other, IP20

Product Type : Programmable Logic Controller (PLC)

Frequency : 50/60 Hz

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry