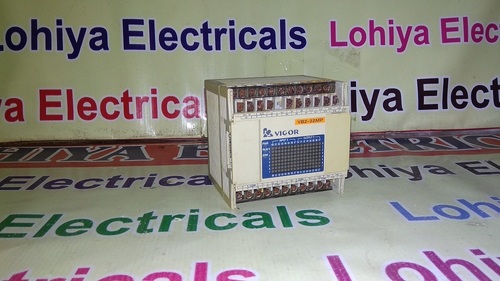

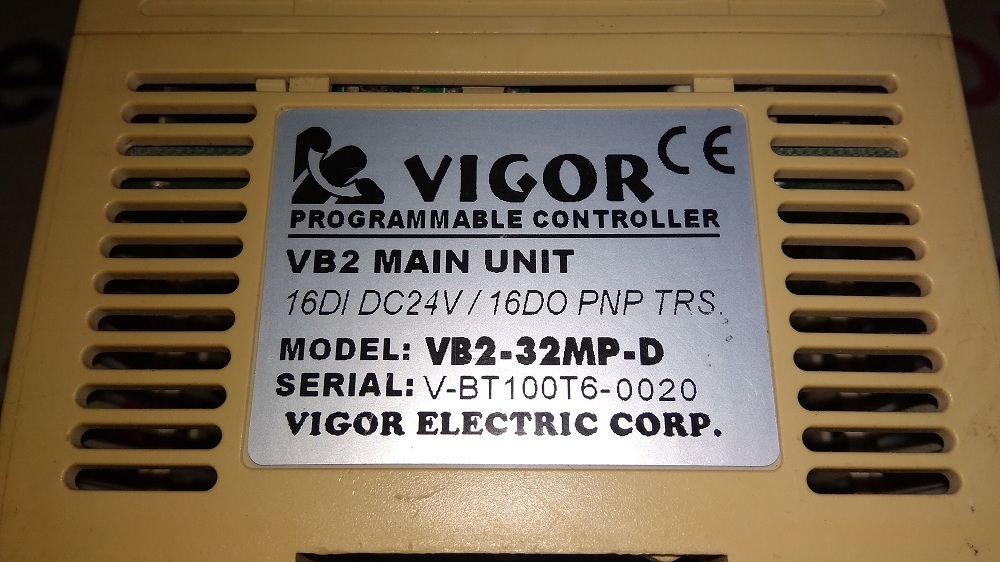

VIGOR PLC

VIGOR PLC Specification

- Display

- LED Display

- IP Rating

- IP20

- Mounting Type

- DIN Rail

- Installation Type

- DIN Rail Mountable

- Output

- 8 Relay Outputs

- Phase

- Single Phase

- Protection Level

- IP20

- Usage & Applications

- Automation Systems, Machine Control

- Current

- 600 mA

- Features

- Expandable Modules, Program Memory, Real-Time Clock

- Frequency

- 50/60 Hz

- Connectivity Type

- RS-232/RS-485 Communication

- Product Type

- Programmable Logic Controller (PLC)

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0-55C

- Input

- 12 Inputs (Digital)

- Application

- Industrial Automation, Process Control

- Supply Voltage

- 24V DC

- Accuracy

- High Precision Control

- Dimension (L*W*H)

- 110 x 90 x 80 mm

- Weight

- 350g

- Expansion

- Supports Digital and Analog Expansion Modules

- Communication Protocols

- Modbus RTU Supported

- Scan Time

- 0.55 s/instruction

- PLC Series

- VIGOR VB Series

- Backup Memory

- EEPROM (program retained during power loss)

- HMI Support

- Yes, supports standard HMI devices

- Program Capacity

- 8K Steps

About VIGOR PLC

Discover the magnificent VIGOR PLC, engineered for excellence in industrial automation and machine control. Add to Cart this hot deal for top-tier process control with 8K steps of program capacity, gilt-edged real-time clock, and high precision accuracy. The VB Series supports expandable modules for both digital and analog applications. Reliable Modbus RTU protocol ensures seamless communication, while the LED display and EEPROM backup memory protect your program data. DIN rail mountable and featuring IP20 protection level, this device is a superb investment for suppliers and traders seeking robust automation solutions.

Application Powerhouse & Gilt-Edged Features

VIGOR PLC excels across diverse application media, handling industrial automation, machine control, and process control tasks with high precision. Its expandable module support and real-time clock heighten operation versatility, while compatibility with standard HMI devices adds intuitive interaction. With backup memory retention and LED display insights, this PLC delivers gilt-edged reliability, making it essential for demanding environments where performance and adaptability are paramount.

Domestic Market Strength & Export Promise

VIGOR PLC commands strong presence in the domestic mar, with certifications attesting to its quality. Proposal amounts are easily customized for project needs, ensuring order completion is efficient and timely. Main domestic market benefits from rapid supply and support, while main export markets recognize VIGOR PLC for its reliability and performance. Certified standards and versatility make it a sought-after choice for global industrial automation proposals.

Application Powerhouse & Gilt-Edged Features

VIGOR PLC excels across diverse application media, handling industrial automation, machine control, and process control tasks with high precision. Its expandable module support and real-time clock heighten operation versatility, while compatibility with standard HMI devices adds intuitive interaction. With backup memory retention and LED display insights, this PLC delivers gilt-edged reliability, making it essential for demanding environments where performance and adaptability are paramount.

Domestic Market Strength & Export Promise

VIGOR PLC commands strong presence in the domestic mar, with certifications attesting to its quality. Proposal amounts are easily customized for project needs, ensuring order completion is efficient and timely. Main domestic market benefits from rapid supply and support, while main export markets recognize VIGOR PLC for its reliability and performance. Certified standards and versatility make it a sought-after choice for global industrial automation proposals.

FAQs of VIGOR PLC:

Q: How does the VIGOR PLC support high precision control in industrial automation?

A: The VIGOR PLC utilizes advanced programming capacity and swift scan times, resulting in high precision control vital for automation processes. It regulates systems with excellent accuracy, ensuring reliable performance.Q: What process is involved in connecting the VIGOR VB Series to an HMI device?

A: Connecting to HMI devices is straightforward, as the VIGOR VB Series supports standard protocols and ports. Simply link the communication interfaces, such as RS-232 or RS-485, and configure the settings for seamless monitoring and management.Q: Where can the VIGOR PLC be installed within an automation system?

A: Thanks to its DIN rail mountable design and compact dimensions, the VIGOR PLC can be installed conveniently in control panels or enclosures within any industrial automation setup.Q: When is the backup memory feature beneficial for users?

A: The EEPROM backup memory retains program data during power losses, ensuring that operations resume quickly and efficiently after interruptionsespecially critical in environments demanding minimal downtime.Q: What are the main benefits for suppliers and traders who choose VIGOR PLC?

A: Suppliers and traders benefit from VIGOR PLCs reliability, expansive programmability, and robust communication protocols, enabling them to deliver cost-effective solutions and cater to broad automation needs confidently.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in VIGOR MODULE CPU PLC Category

VIGOR MODULE

Display : LED Digital

Operating Temperature : 0C to 60C

IP Rating : IP20

Mounting Type : DIN Rail Mount

Installation Type : Panel Mount

Weight : 350 g

VIGOR PLC

Display : LED/Indicator (on unit)

Operating Temperature : 0C to 55C

IP Rating : IP20

Mounting Type : DIN Rail Mount

Installation Type : DIN Rail Mounting

Weight : About 0.5 kg

VIGOR PLC

Display : LED/LCD (as per model)

Operating Temperature : 0C to 55C

IP Rating : IP20

Mounting Type : Panel or DIN Rail Mountable

Installation Type : DIN Rail Mounting

Weight : Approx. 400g

VIGOR PLC

Display : LED Indicator

Operating Temperature : 0C to 55C

IP Rating : IP20

Mounting Type : DIN rail

Installation Type : DIN Rail Mounting

Weight : Approx. 350g

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry