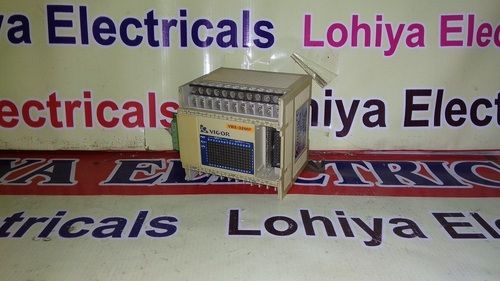

VIGOR PLC

VIGOR PLC Specification

- Current

- 0.6A

- Usage & Applications

- Process Automation, Factory Control Systems

- Output

- Relay Outputs: 8

- Installation Type

- DIN Rail Mounting

- Protection Level

- Over Voltage and Short Circuit Protection

- Mounting Type

- Panel or DIN Rail Mountable

- IP Rating

- IP20

- Phase

- Single Phase

- Connectivity Type

- RS232/RS485 Communication

- Frequency

- 50/60 Hz

- Features

- Compact Design, High Speed Processing, Expandable I/O

- Display

- LED/LCD (as per model)

- Product Type

- PLC (Programmable Logic Controller)

- Operating Temperature

- 0°C to 55°C

- Working Temperature

- 0°C to 55°C

- Input

- Digital Inputs: 12, Analog Inputs: 2

- Application

- Industrial Automation, Machinery, Production Lines

- Supply Voltage

- 220V AC

- Accuracy

- High Accuracy Control

- Dimension (L*W*H)

- Approx. 135 x 90 x 65 mm

- Weight

- Approx. 400g

- Response Time

- < 1 ms

- Programming Language

- Ladder Logic, Instruction List

- Expansion Capability

- I/O Expansion Modules Available

- Enclosure Material

- ABS Plastic Housing

- Certificates

- CE, ISO9001 Certified

- Communication Ports

- RS232, RS485 (Modbus Supported)

- Operating System

- Real-Time OS Embedded

- Ambient Humidity

- 5% - 95% RH (Non-Condensing)

- Program Memory

- 16K Steps

- Cooling Method

- Natural Air Cooling

- Backup Battery

- Supported

About VIGOR PLC

Versatility & Applicability of VIGOR PLC

VIGOR PLC is widely used by suppliers, traders, and manufacturers for factory control systems, process automation, and high-speed machinery. Suitable for various production lines and industrial set-ups, this controller is perfect for environments requiring dependable panel or DIN Rail mounting. Its compact and expandable nature allows for applications in diverse sectors, ensuring operational excellence across assembly plants, warehouses, and automated facilities where high accuracy and rapid response are crucial.

Export Markets & Distribution Policies

VIGOR PLC is frequently exported to major industrial markets, with sale price options to match procurement needs. Stock is ready for prompt shipment, facilitating smooth exchanges as per supplier policy. Sample units are available for qualified orders, ensuring clients can evaluate splendiferous performance before commitment. Delivery time is typically swift, depending on location and order size, prioritizing customer satisfaction and maintaining robust inventory levels for seamless global distribution.

FAQs of VIGOR PLC:

Q: How does VIGOR PLC ensure high accuracy and rapid response in industrial applications?

A: VIGOR PLC utilizes a real-time embedded OS, 16K Steps program memory, and processing response time less than 1 ms, delivering dependable and precise control for automation tasks.Q: What types of inputs and outputs are supported by VIGOR PLC?

A: VIGOR PLC supports 12 digital inputs, 2 analog inputs, and 8 relay outputs, making it suitable for a wide range of automation needs and process integration.Q: Where can VIGOR PLC be installed for optimal operation?

A: VIGOR PLC is designed for flexible installation; it can be panel or DIN Rail mounted, allowing use in various industrial settings including production lines and machinery control stations.Q: What is the process to expand VIGOR PLCs capabilities beyond standard I/O?

A: I/O expansion modules are available, enabling users to augment the controllers input/output capacity as operational demands increase, maintaining system scalability.Q: When is it recommended to use the backup battery feature in VIGOR PLC?

A: The backup battery should be used when uninterrupted operation and preservation of program data during power outages or maintenance events are critical for productivity.Q: What benefits do the CE and ISO9001 certifications offer for VIGOR PLC users?

A: These certifications guarantee global compliance, safety, and quality assurance, providing confidence in durable operation and compatibility with industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VIGOR MODULE CPU PLC Category

VIGOR MODULE

Accuracy : ±1%

Installation Type : Panel Mount

Protection Level : Other, IP20

Product Type : VIGOR MODULE

Mounting Type : DIN Rail Mount

IP Rating : IP20

VIGOR PLC

Accuracy : High accuracy, <0.5% (Analog channel)

Installation Type : DIN Rail / Panel Mounting

Protection Level : Other, Surge and Overvoltage Protection Builtin

Product Type : Programmable Logic Controller (PLC)

Mounting Type : DIN Rail Mountable

IP Rating : IP20

VIGOR PLC

Accuracy : High Processing Accuracy (Exact value depends on model)

Installation Type : DIN Rail Mounting

Protection Level : Other, Short circuit and overload protection

Product Type : Programmable Logic Controller (PLC)

Mounting Type : DIN Rail Mount

IP Rating : IP20

VIGOR PLC

Accuracy : High Precision Control

Installation Type : DIN Rail Mountable

Protection Level : Other, IP20

Product Type : Programmable Logic Controller (PLC)

Mounting Type : DIN Rail

IP Rating : IP20

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry