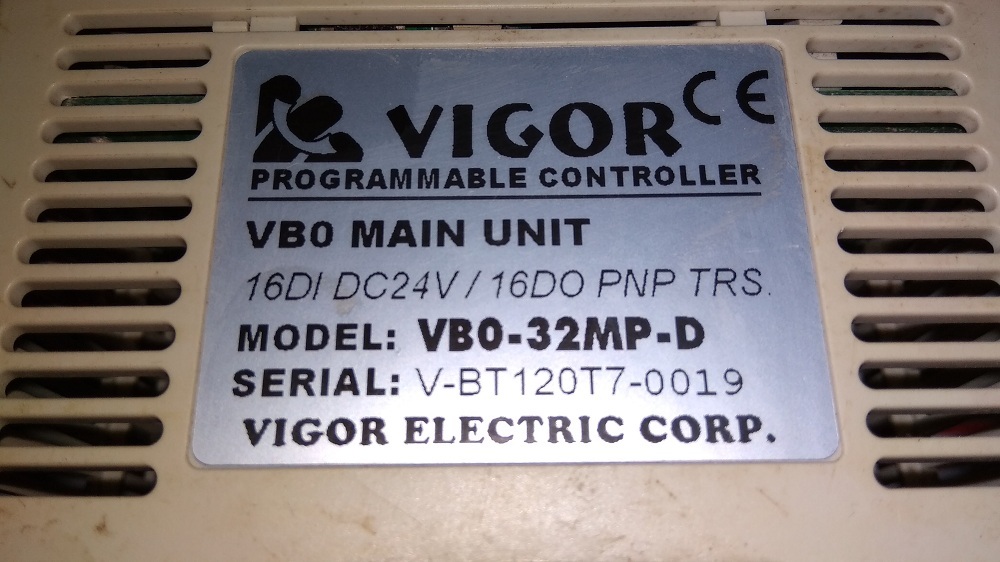

VIGOR PLC

VIGOR PLC Specification

- Current

- 0.5A (typical)

- Mounting Type

- DIN Rail Mountable

- Installation Type

- DIN Rail / Panel Mounting

- Switch Type

- Electronic switching (Relay/Transistor output type dependent)

- Frequency

- 50/60Hz

- Features

- Compact design, Modular expansion, User-friendly programming, High-speed processing

- Protection Level

- Surge and Overvoltage Protection Built-in

- Output

- Relay/Transistor, Digital/Analog Output

- Measuring Range

- Depends on module; Digital: 0/24V DC, Analog: 0-10V/4-20mA

- Connectivity Type

- RS485/RS232 Ethernet (optional)

- Display

- LED/LCD Indicator (varies by model)

- Phase

- Single Phase (24VDC) / Three Phase (220VAC optional)

- Usage & Applications

- Industrial Control Panel, Automation Systems

- IP Rating

- IP20

- Product Type

- Programmable Logic Controller (PLC)

- Operating Temperature

- 0C to 55C

- Working Temperature

- 0C to 55C

- Input

- Digital/Analog Input

- Application

- Industrial Automation, Machine Control, Process Automation

- Supply Voltage

- 24V DC / 220V AC (model dependent)

- Accuracy

- High accuracy, <0.5% (Analog channel)

- Dimension (L*W*H)

- 120mm x 90mm x 60mm (typical, varies by model)

- Weight

- 350g (approximate)

- Number of Inputs

- 14 (expandable depending on model)

- Programming Software

- Vigor VPLSoft compatible

- Communication Protocols

- Modbus RTU, Modbus TCP/IP (model specific)

- Number of Outputs

- 10 (expandable depending on model)

- Memory Type

- Flash memory for program storage

- Expansion Capability

- Supports I/O Expansion Modules

- Scan Time

- < 1ms/K instructions

- Program Capacity

- Up to 8,000 steps

- Power Consumption

- < 10W

About VIGOR PLC

Versatility and Commercial Applications

The VIGOR PLC is exceptionally suitable for use in industrial automation, machine control panels, and process automation. Its robust material features include a compact and modular design built for high performance and durability. Engineered for first-class reliability, the PLC serves as a champion control solution in various commercial settings, such as manufacturing plants and process industries, delivering consistent and accurate results with every application.

Packaging, Sample Availability, and Market Reach

Shipped goods are carefully secured to ensure safe transit, maintaining the integrity of the VIGOR PLC during shipment. Packaging details include compact and protective boxing, perfect for industrial hardware. Secure shipping options are available for all orders. Sample units can be provided upon request, allowing for pre-purchase inspection. The main domestic market for the VIGOR PLC covers both urban and industrial sectors, supporting widespread deployment for automation projects.

FAQs of VIGOR PLC:

Q: How can the VIGOR PLC be integrated into existing automation systems?

A: The VIGOR PLC can be easily integrated into existing automation infrastructure using its modular expansion capability, flexible communication protocols (Modbus RTU, Modbus TCP/IP), and user-friendly VPLSoft programming software.Q: What makes the VIGOR PLC suitable for industrial control applications?

A: The PLCs robust surge and overvoltage protection, fast scan time, high accuracy, and expandable I/O make it ideal for demanding industrial processes and machine control.Q: Where can the VIGOR PLC be installed within a facility?

A: The unit is designed for DIN rail or panel mounting, allowing for flexible installation in industrial control panels and automation cabinets.Q: What is the process for obtaining a sample of the VIGOR PLC?

A: Samples are available upon request. Interested customers can contact the supplier or trader to arrange for shipment and secure delivery of sample units.Q: What are the benefits of using the VIGOR PLC in process automation?

A: Key benefits include high-speed processing, accurate analog control, modular expansion for future growth, and easy integration into existing systemsall supporting efficient and reliable automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VIGOR MODULE CPU PLC Category

VIGOR MODULE

Current : 2A

Accuracy : 1%

Dimension (L*W*H) : 120 mm x 75 mm x 40 mm

Input : 220V AC

Application : Industrial Automation

Installation Type : Panel Mount

VIGOR PLC

Current : Max 2A per output (Relay), Max 0.75A per output (Transistor)

Accuracy : High Processing Accuracy (Exact value depends on model)

Dimension (L*W*H) : Approx. 120mm x 90mm x 60mm (varies by model)

Input : Digital and Analog Inputs

Application : Industrial Automation, Machine Control, Process Monitoring

Installation Type : DIN Rail Mounting

VIGOR PLC

Current : 500 mA

Accuracy : High Precision Control, 0.1%

Dimension (L*W*H) : 120 mm x 90 mm x 40 mm

Input : 8 Digital Inputs, 6 Analog Inputs

Application : Industrial Automation, Machine Control

Installation Type : DIN Rail Mounted

VIGOR PLC

Current : 0.6A

Accuracy : High Accuracy Control

Dimension (L*W*H) : Approx. 135 x 90 x 65 mm

Input : Digital Inputs: 12, Analog Inputs: 2

Application : Industrial Automation, Machinery, Production Lines

Installation Type : DIN Rail Mounting

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry