Call:

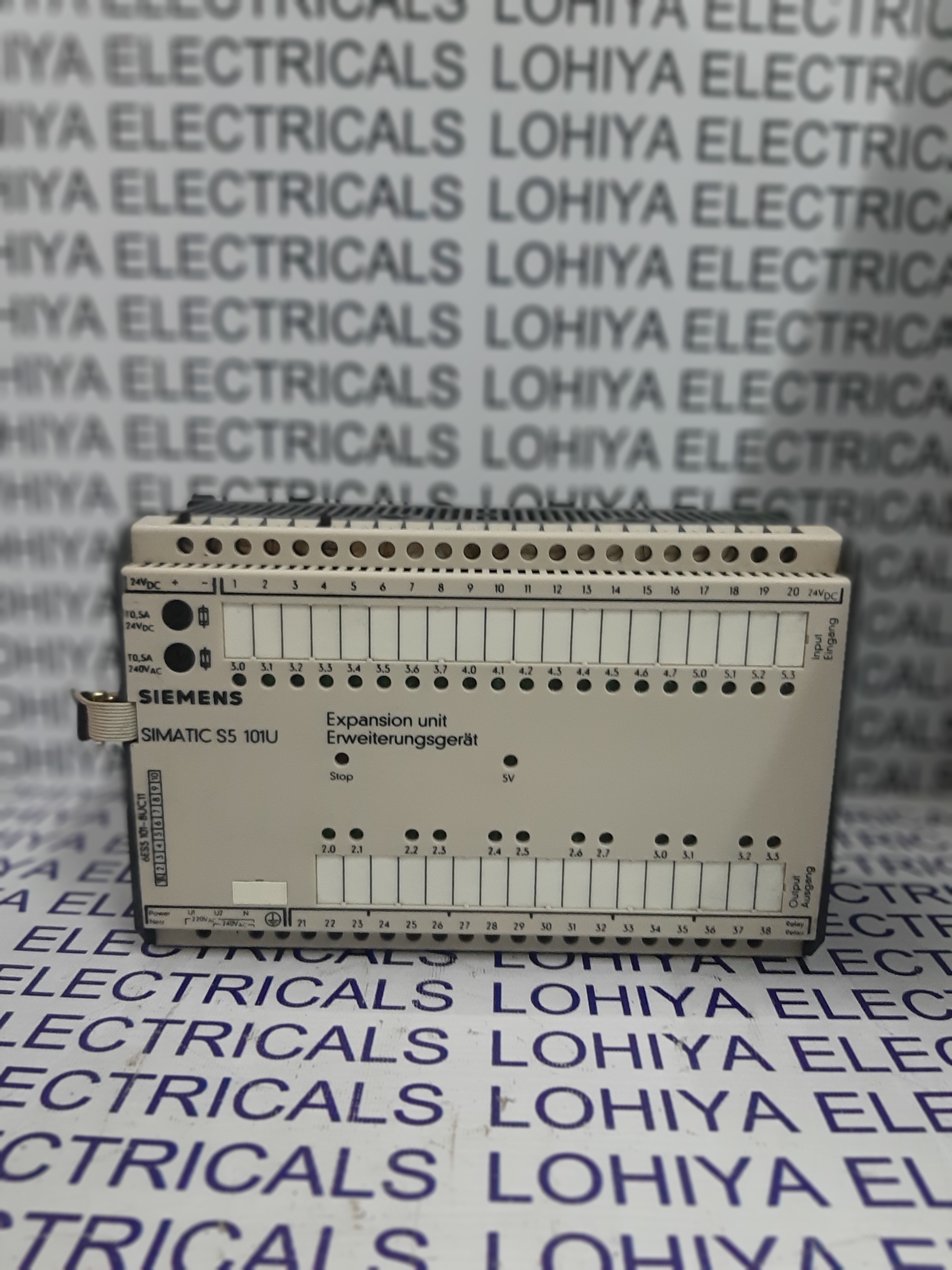

SIEMENS SIMATIC S5 CONTROLLERS

SIEMENS SIMATIC S5 CONTROLLERS Specification

- Control System

- Programmable Logic Controller (PLC)

- Operating Voltage

- 24V DC / 230V AC

- Base Material

- Plastic & Metal

- Rated Operation Voltage

- 24V DC / 230V AC

- Rated Insulation Voltage

- 500V

- Rated Current

- 0.5A-2A (per channel)

- Protection Class

- Class I

- Panel Type

- Rack Mount

- Thickness

- Standard Modular

- Connectivity Type

- RS232, Parallel Bus

- Components

- CPU, Input/Output (I/O) modules, Power Supply, Communication Processor

- Protection Level

- IP20

- Cooling System

- Natural Air Cooling

- Cabinet Material

- Steel Enclosure

- Current Rating

- 2A max (varies by module)

- Features

- Expandable Modules, Reliable Operation, Modular Design

- Cover Material

- Plastic

- Way

- Modular Multi-Way

- Product Type

- Programmable Logic Controller (PLC)

- Material

- Industrial Grade Plastic, Metal Components

- Surface Finish

- Matte

- Standard

- IEC 61131-2

- Surface Color

- Beige Grey

- Rated Voltage

- 24V DC

- Frequency (MHz)

- 50/60 Hz

- Maximum Output Current

- 2A

- Dimension (L*W*H)

- Approx. 400 x 150 x 250 mm

- Application

- Industrial Automation, Process Control, Machine Automation

- IP Rating

- IP20

- Display Type

- LED Status Indicators

- Programming Language

- STEP 5

- Relative Humidity

- 5% to 95% non-condensing

- Mounting Method

- DIN rail and rack system

- Power Consumption

- Varies by configuration; typically < 50 W

- Ambient Operating Temperature

- 0°C to +60°C

- Storage Temperature

- -25°C to +70°C

- Legacy Support

- Yes, support for older Siemens automation systems

- Communication Protocols

- Profibus, AS-Interface, proprietary Siemens protocols

- Expansion

- Supports various I/O and communication expansion modules

About SIEMENS SIMATIC S5 CONTROLLERS

Experience peerless automation value with SIEMENS SIMATIC S5 CONTROLLERS, the optimum solution for industrial process control. Their crackerjack design ensures robust operation across varied applications, supporting DIN rail and rack mounting for effortless installation. With STEP 5 programming, modular multi-way expansion, and advanced communication via Profibus, AS-Interface, and Siemens proprietary protocols, these controllers deliver legacy support and reliable power efficiency (<50W). Constructed with industrial-grade materials, conforming to IEC 61131-2, and protected up to IP20, they provide a secure, scalable, and long-lasting foundation for your automation needs. Order now for lasting performance and compatibility.

Comprehensive Application and Usage

SIEMENS SIMATIC S5 CONTROLLERS excel in varied application media, from industrial automation to machine process control. Ideal for plant sites, factories, and production lines, they deliver precise direction of use via programmable logic (PLC) functionality and LED indicators. Simply mount on DIN rail or rack systems, connect the required modules, and configure using STEP 5. Their modular approach ensures seamless integration, optimizing operations in complex and large-scale environments with effortless expansion and connectivity.

Export, Ports, and Fast Delivery Services

Serving main export markets that include Asia, the Middle East, and Europe, SIEMENS SIMATIC S5 CONTROLLERS are shipped using reliable transport services and efficient FOB ports in India. Quick dispatch options minimize lead time, ensuring rapid delivery and reduced charge on logistics. Domestically, major industrial markets across India are covered with dedicated support to streamline procurement and after-sales service, reinforcing dependable supply and customer satisfaction for all your automation infrastructure needs.

Comprehensive Application and Usage

SIEMENS SIMATIC S5 CONTROLLERS excel in varied application media, from industrial automation to machine process control. Ideal for plant sites, factories, and production lines, they deliver precise direction of use via programmable logic (PLC) functionality and LED indicators. Simply mount on DIN rail or rack systems, connect the required modules, and configure using STEP 5. Their modular approach ensures seamless integration, optimizing operations in complex and large-scale environments with effortless expansion and connectivity.

Export, Ports, and Fast Delivery Services

Serving main export markets that include Asia, the Middle East, and Europe, SIEMENS SIMATIC S5 CONTROLLERS are shipped using reliable transport services and efficient FOB ports in India. Quick dispatch options minimize lead time, ensuring rapid delivery and reduced charge on logistics. Domestically, major industrial markets across India are covered with dedicated support to streamline procurement and after-sales service, reinforcing dependable supply and customer satisfaction for all your automation infrastructure needs.

FAQs of SIEMENS SIMATIC S5 CONTROLLERS:

Q: How do you mount the SIEMENS SIMATIC S5 CONTROLLERS in an industrial setting?

A: These controllers support both DIN rail and rack system mounting. Simply select your preferred method based on available space and system architecture, then secure the controller modules and connect necessary expansions as per the installation guide.Q: What programming language and interface are used with the SIEMENS SIMATIC S5?

A: The SIMATIC S5 utilizes STEP 5 as its primary programming language. Communication interfaces include Profibus, AS-Interface, proprietary Siemens protocols, as well as RS232 and parallel bus for connectivity.Q: When should you consider using expansion modules for these controllers?

A: Expansion modules are recommended when you need to scale your system by adding more inputs, outputs, or communication channels, ensuring optimum adaptability for large or evolving automation projects.Q: Where can SIMATIC S5 CONTROLLERS be applied effectively?

A: They are highly effective in industrial automation, process control systems, machine automation, and environments demanding reliable, programmable control and legacy system integration.Q: What is the typical power consumption and how does it benefit users?

A: Power consumption is generally under 50W, which translates to energy efficiency, lower operational costs, and reliable thermal performance thanks to natural air cooling design.Q: How does legacy support benefit ongoing industrial operations?

A: Legacy support ensures continued compatibility with older Siemens automation systems, protecting earlier investments while allowing gradual system upgrades and minimized operational disruption.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry