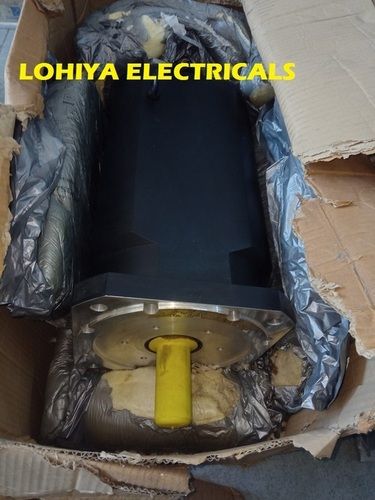

SERVO MOTOR

SERVO MOTOR Specification

- Connectivity Type

- Wired

- Usage & Applications

- CNC Machines, Robotics, Industrial Automation, Conveyor Systems

- Features

- High Torque, Low Noise, Energy Efficient, Precise Control

- Phase

- Single/Three Phase (as per model)

- Frequency

- 50/60 Hz

- Protection Level

- IP54 / IP65 (model dependent)

- Pole Type

- 2/4 Poles (depends on model)

- IP Rating

- IP54 / IP65

- Mounting Type

- Flange / Foot Mount

- Output

- Rotational Motion

- Installation Type

- Flange Mount / Foot Mount

- Sensor Type

- Encoder / Resolver (as per model)

- Current

- Varies as per model (typically 2-5A)

- Product Type

- Servo Motor

- Operating Temperature

- -20C to +50C

- Working Temperature

- -20C to +50C

- Input

- AC or DC (as per model specification)

- Diameter

- Standard or as specified

- Application

- Automation, Robotics, CNC Machinery, Packaging Machines

- Supply Voltage

- 220-240V AC / 24V DC (as per type)

- Accuracy

- High Precision Positioning

- Dimension (L*W*H)

- Standard/Custom (depends on model)

- Weight

- Approx. 2-5 kg (varies with model)

- Bearing Type

- Ball Bearing

- Cable Length

- Standard 1.5 m / Customized

- Cooling Method

- Natural Air Cooled

- Control Method

- Pulse Width Modulation (PWM), Analog/Digital Control

- Encoder Resolution

- Up to 2500 ppr

- Response Time

- <50 ms (depending on load)

- Application Industries

- Textile, Printing, Packing, Medical Equipment, Electronics

- Noise Level

- <60 dB

- Material

- Aluminum / Cast Iron body

- Rated Speed

- 1500 rpm / 3000 rpm (Varies with model)

- Insulation Class

- Class F or H

- Torque

- Rated up to 10 Nm or more (model dependent)

About SERVO MOTOR

Dynamic Applications of Servo Motors

SERVO MOTORS demonstrate remarkable versatility, dominating numerous fields such as CNC machines, robotics, printing, textiles, packaging machines, and industrial automation. Specific uses include precise positioning, speed regulation, and controlled torque delivery. General use comprises motion control in conveyor systems and electronics assembly. Direction of use typically involves flange or foot mount installation, ensuring imposing performance in both repetitive and complex automation processes.

Sample Policy & Domestic Supply Network

Our SERVO MOTOR sample policy guarantees convenient access for evaluation prior to bulk investment. Sample units are supplied to clients across Indias main domestic market, subject to prevailing freight charges and sample outlay. This initiative ensures customers can thoroughly assess the product before substantial procurement, supporting confident and informed decision-making in their automation projects.

FAQs of SERVO MOTOR:

Q: How do I choose the right SERVO MOTOR model for my application?

A: Model selection depends on parameters such as required speed, torque, control method, insulation class, and mounting type. Evaluate your applications needssuch as CNC machinery, robotics, or packagingthen match with the motors specifications for optimal performance.Q: What are the primary benefits of using this SERVO MOTOR?

A: Benefits include high precision positioning, imposing torque delivery, rapid response time (<50 ms), and superior durability with IP54/IP65 protection. These features ensure reliable and efficient automation in demanding industrial environments.Q: Where can SERVO MOTORS be applied most effectively?

A: They are ideal for automation, robotics, electronics, medical equipment, and machinery involving repetitive or intricate movement, such as textile and packaging industries, due to their energy efficiency and precise control.Q: When should I use flange mount versus foot mount installation?

A: Flange mount is recommended for applications requiring direct coupling to mechanisms, while foot mount offers stability for standalone motor arrangements. Your specific application and available space will determine the most suitable mounting method.Q: What is the process for obtaining a sample SERVO MOTOR?

A: Contact our supplier network or trader in India to request a sample. Samples are supplied after confirming freight and sample outlay details, ensuring customers assess the product before large-scale purchase.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B&R SERVO MOTOR Category

Servo Motor

Working Temperature : 20C to +80C

Mounting Type : Flange Mounted

IP Rating : IP65

Protection Level : IP65

Dimension (L*W*H) : 120 mm x 80 mm x 80 mm

Sensor Type : Position Sensor

B&r Servo Motor 8msa2x.e5-i6

Working Temperature : 20C to +40C

Mounting Type : Flange Mount

IP Rating : IP65

Protection Level : IP65

Dimension (L*W*H) : Approx. 202 mm x 102 mm x 84 mm

Sensor Type : Integrated Encoder

B&R SERVO MOTOR 8MSA8M.E1-E1

Working Temperature : 20C to +40C

Mounting Type : Flange Mount

IP Rating : IP65

Protection Level : IP65

Dimension (L*W*H) : Approx. 322 mm (length) x 130 mm (flange diameter)

Sensor Type : Incremental Encoder

B&R SERVO MOTOR 8MSA5L.E0-B500-1

Working Temperature : 20C to +40C

Mounting Type : Flange Mounted

IP Rating : IP65

Protection Level : IP65

Dimension (L*W*H) : 520 mm (Length, approx.)

Sensor Type : Integrated encoder (Resolver/EnDat)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry