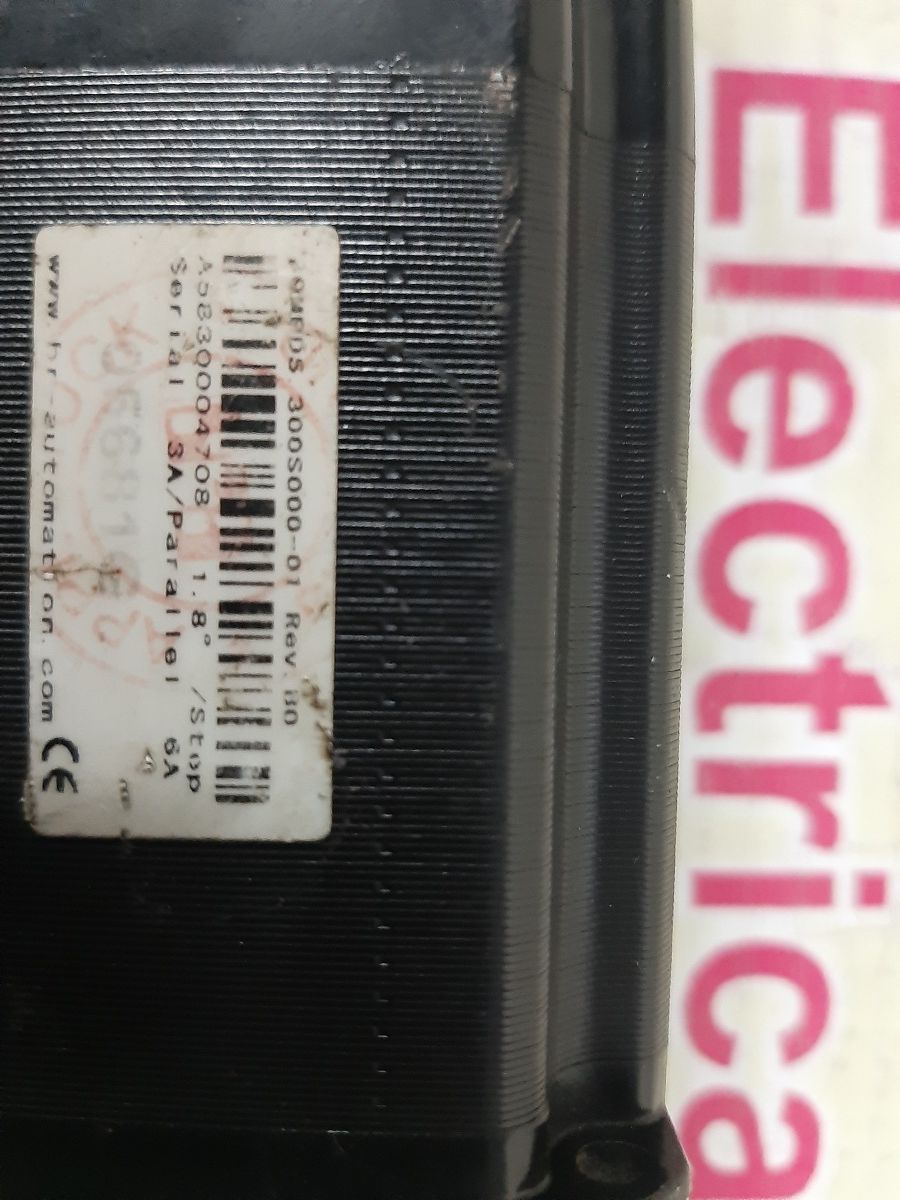

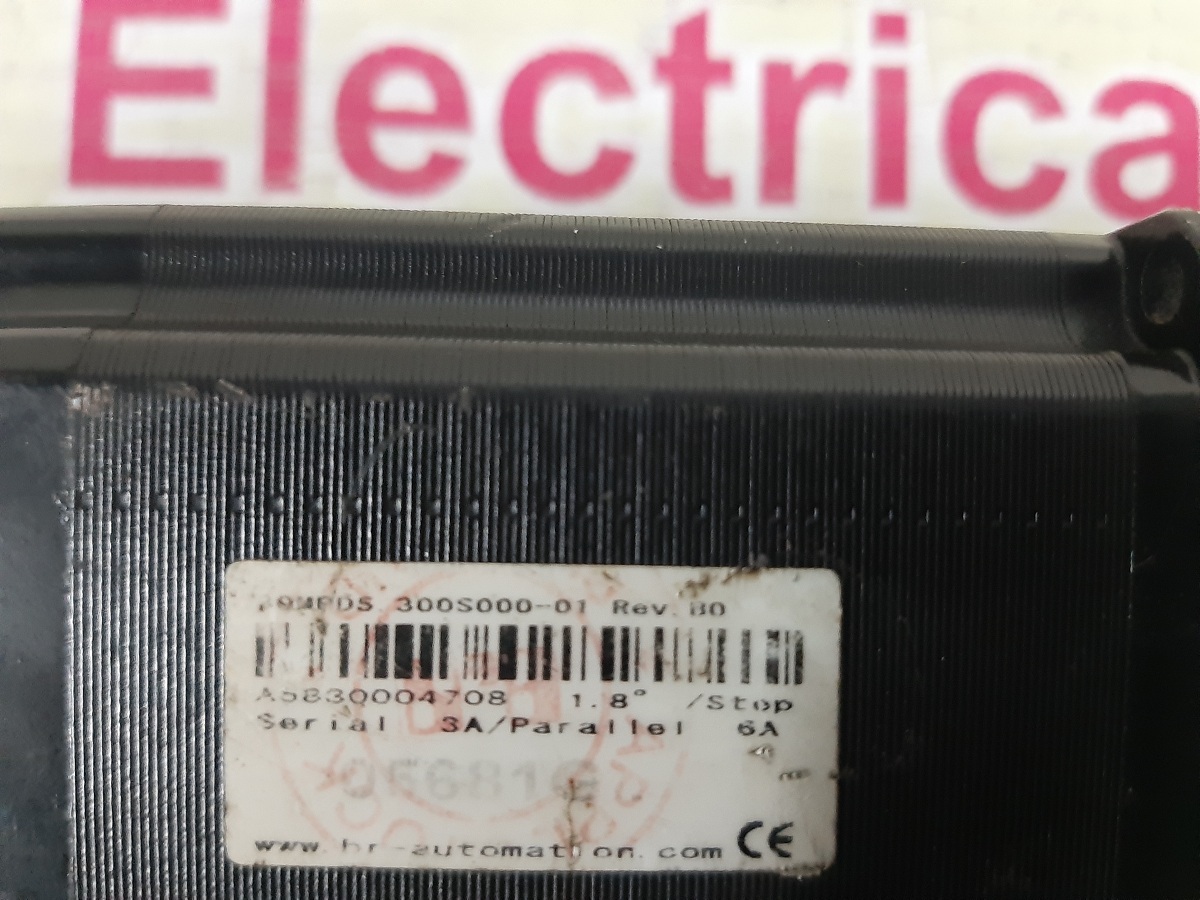

Servo Motor

Servo Motor Specification

- Switch Type

- Electronic

- Protection Level

- IP65

- Output

- Rotational motion

- Frequency

- 50/60 Hz

- Sensor Type

- Position Sensor

- Connectivity Type

- Wired

- Installation Type

- Flange Mount

- IP Rating

- IP65

- Phase

- Single Phase

- Mounting Type

- Flange Mounted

- Features

- High Precision, Fast Response, Low Noise

- Current

- 2.5A

- Usage & Applications

- CNC Machines, Packaging, Conveyors

- Pole Type

- 2 Pole

- Product Type

- Servo Motor

- Operating Temperature

- -20C to +80C

- Working Temperature

- -20C to +80C

- Input

- 220V AC

- Diameter

- 50 mm

- Application

- Industrial Automation, Robotics

- Supply Voltage

- 220V AC

- Accuracy

- 0.1

- Dimension (L*W*H)

- 120 mm x 80 mm x 80 mm

- Weight

- 2.1 kg

- Maximum Speed

- 3000 RPM

- Brake

- Optional Electromagnetic Brake

- Bearing Type

- Ball Bearing

- Life Expectancy

- 20,000 Hours

- Ambient Humidity

- <90% RH (Non-condensing)

- Housing Material

- Aluminium Alloy

- Shaft Type

- Keyed

- Insulation Class

- Class B

- Cooling Method

- Natural Air Cooled

- Torque Rating

- 1.27 Nm

About Servo Motor

Servo Motor: Superior Precision for Industrial Automation

Experience unmatched excellence with this Servo Motor, purpose-built for demanding applications such as robotics, CNC machines, conveyors, and packaging systems. Its high torque, IP65-rated protection, and flange mount design guarantee robust performance even in intense industrial environments. The integration of a position sensor and optional electromagnetic brake enables high-precision control, making it a competitive choice for manufacturers aiming for reliability, efficiency, and remarkable operational accuracy in their automated processes.

Packing & Dispatch: Global Reach with Secure Exchange

Each Servo Motor is securely packed and dispatched in durable packaging to ensure safe transit and delivery. Our main export markets encompass Asia, Europe, and the Middle East, meeting international standards at every stage. Payment terms include advance, TT, and secure online exchanges, ensuring transparent and flexible transactions. Shipped swiftly and handled with care, our products aim to provide seamless integration into global supply chains for our valued partners and customers.

FAQs of Servo Motor:

Q: How does the keyed shaft enhance the servo motors reliability in industrial settings?

A: The keyed shaft ensures a secure and robust mechanical connection, reducing slippage and guaranteeing precise rotational motion. This contributes significantly to consistent performance and increased longevity in demanding automation and robotics applications.Q: What advantages does the aluminium alloy housing offer?

A: The resplendent aluminium alloy housing provides excellent heat dissipation, resistance to corrosion, and durability, preserving optimal performance in harsh industrial environments and elevating the motors overall life expectancy.Q: When should the optional electromagnetic brake be utilised?

A: The optional electromagnetic brake is beneficial in scenarios requiring high-precision stopping or holding of loads, such as in CNC machines or conveyor systems, offering enhanced control and safety during operation.Q: Where can this servo motor be installed for best performance?

A: Optimised for industrial automation tasks, this motor is ideally installed in CNC machinery, packaging equipment, robotic systems, and conveyors, particularly where high accuracy and reliability are paramount.Q: What is the process for installing this servo motor?

A: Mount the servo motor using its flange on a stable surface, connect the wired inputs to a 220V AC supply, and integrate position sensor and optional brake connections according to the detailed installation manual provided.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B&R SERVO MOTOR Category

B&R SERVO MOTOR 8MSA4L.E0-67

Frequency : 50/60 Hz

Connectivity Type : Electrical Connector

Protection Level : IP65

Product Type : B&R Servo Motor 8MSA4L.E067

Diameter : 90 mm (flange)

Output : 5.7 kW (Nominal)

B&R SERVO MOTOR 8MSA3X.R0-42

Frequency : 50/60 Hz

Connectivity Type : Standard Industrial Servo Connectors

Protection Level : IP65

Product Type : Servo Motor

Diameter : Approx. 60 mm (Flange size)

Output : Rated power 1.2 kW

B&R SERVO MOTOR 8MSA4L.R0-33

Frequency : 50/60 Hz

Connectivity Type : Servo cable and feedback connector

Protection Level : IP65

Product Type : B&R Servo Motor 8MSA4L.R033

Diameter : Approx. 130 mm (Flange)

Output : Continuous torque: 8.7 Nm

B&R SERVO MOTOR 8MSA8M.R0-P1

Frequency : 50/60 Hz

Connectivity Type : Cable connection with connector

Protection Level : IP65

Product Type : Servo Motor

Diameter : Motor flange size: 130 mm

Output : Rated power: 5.4 kW

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry