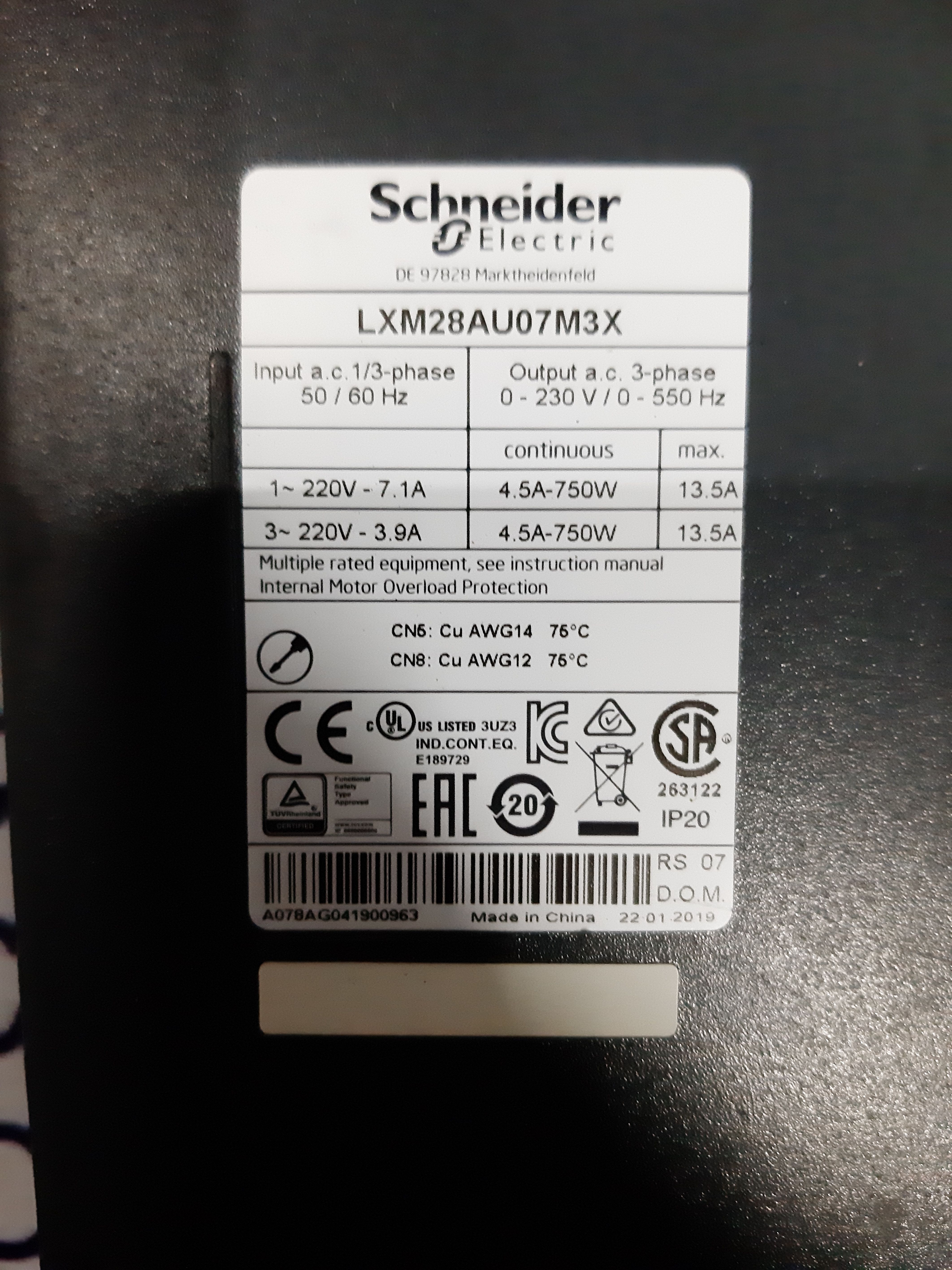

SCHNEIDER ELECTRIC AC SERVO DRIVE

SCHNEIDER ELECTRIC AC SERVO DRIVE Specification

- Rated Power

- 400 W

- Noise Level

- <55 dB

- Features

- Dynamic Braking, Auto-tuning, Multi-mode Operation

- Application

- Automation, CNC Machines, Packaging

- Rated Current

- 2.6 A

- Connector Type

- Screw Terminal

- Power Supply

- AC

- Current Range

- 0-2.6 A

- Phase

- Single/Three Phase

- Working Temperature

- 0C to 55C

- Power Factor

- >0.95

- Operating Temperature

- 0C to 55C

- Cooling Method

- Forced Air Cooling

- Output Type

- Analog / Digital

- Output Current

- 2.6 A

- Product Type

- AC Servo Drive

- Output Power

- 400 W

- Output Frequency

- 0-400 Hz

- Input Voltage

- 200-240V AC

- Voltage Protection

- Overvoltage, Undervoltage, Short Circuit

- Efficiency

- >95%

- Material

- Industrial Grade ABS & Metal

- Line Regulation

- 0.1%

- Storage Temperature

- -25C to 70C

- Weight

- 2.5 kg

- Acceleration/Deceleration Time

- 0.01 to 30 seconds

- Display Type

- LED Digital Display

- Mounting Type

- Panel Mount

- Humidity Range

- <90% RH (non-condensing)

- Communication Interface

- RS-232/485, Modbus

- System Compatibility

- Integrated with PLC and HMI systems

- Environmental Compliance

- RoHS and Reach

- Sampling Rate

- 2 kHz

- Regenerative Function

- Available

- Response Speed

- 1 kHz

- Encoder Feedback

- Supports Incremental Encoder

- Control Method

- Position, Speed, Torque Control

- Insulation Resistance

- >50 M (500V DC)

- Protection Class

- IP20

About SCHNEIDER ELECTRIC AC SERVO DRIVE

Exceptional Features and Usage Direction

The SCHNEIDER ELECTRIC AC SERVO DRIVE offers dynamic braking, auto-tuning, and multi-mode operation, elevating machine performance in CNC and packaging environments. Easy panel mount installation and LED digital display streamline monitoring, while the position, speed, and torque control enhance accuracy. Users should connect the drive using screw terminals and integrate it effortlessly with PLC and HMI systems. Ideal for industrial automation, this unmatchable drive serves precise motion control applications with maximum stability and efficiency.

Order and Certification Details for Hassle-Free Logistics

Order completion for the SCHNEIDER ELECTRIC AC SERVO DRIVE is seamless via Indias main FOB ports, ensuring rapid and secure valuation and delivery. Certified with RoHS and Reach standards, the product guarantees environmental compliance. Our sample policy is straightforwardsamples provided as per logistic requirements to aid decision-making. Enjoy transparent, efficient logistics combined with reliable documentation and certification, ensuring your acquisition meets all regulatory and operational standards for industrial automation.

FAQs of SCHNEIDER ELECTRIC AC SERVO DRIVE:

Q: How does the SCHNEIDER ELECTRIC AC SERVO DRIVE improve automation processes?

A: The servo drive enhances automation with precise position, speed, and torque control, integration capability with PLC/HMI systems, and advanced protection features, resulting in smoother and more reliable machine operation.Q: What certifications does the SCHNEIDER AC SERVO DRIVE comply with?

A: The drive meets RoHS and Reach environmental compliance certifications, ensuring safety and environmental standards are adhered to during usage.Q: When should I use dynamic braking or auto-tuning on the drive?

A: Dynamic braking is used during rapid stopping of machinery to prevent damage, while auto-tuning optimizes performance settings for new installation or after significant changes in machine load.Q: Where can suppliers and traders order or receive product delivery in India?

A: Suppliers and traders can order via Indias major FOB ports, where logistics and order completion are coordinated for efficient delivery.Q: What is the specific benefit of panel mount installation?

A: Panel mount installation offers straightforward integration into industrial control panels, saving space, improving accessibility, and facilitating seamless system management for operators.Q: How does the regenerative function contribute to system efficiency?

A: The regenerative function recycles energy generated during braking, reducing overall power consumption and increasing operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

SCHNEIDER ELECTRIC AC SERVO DRIVE

Features : Compact design, High Precision, Easy Installation, Builtin protection functions

Application : Industrial Automation, CNC Machines, Packaging, Conveyors

Phase : Other, Single/Three Phase

Product Type : AC Servo Drive

Power Supply : AC Power

Storage Temperature : 20C to +65C

MODICON QUATUM

Features : Hot Swappable, Redundancy support, Expandable, High Speed Processing, Modular design

Application : Industrial Automation, Process Control, Machine Automation

Phase : Single Phase

Product Type : Programmable Logic Controller (PLC)

Power Supply : 100240V AC, 24V DC

Storage Temperature : 40C to +85C

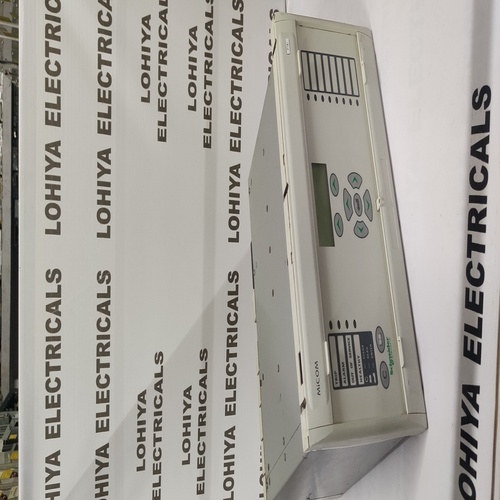

SCHNEIDER MICOM P143 OVERCURRENT AND EARTH FAULT PROTECTION RELAY P143211C3M0468J

Features : Directional, NonDirectional Overcurrent & Earth Fault, Event Recording, Fault Recording, LCD Display, Communication Ports

Application : Feeder Protection, Substation Automation, Motor & Transformer Protection

Phase : Three Phase

Product Type : Overcurrent and Earth Fault Protection Relay

Power Supply : Auxiliary (DC/AC options)

Storage Temperature : 40C to +70C

Schneider XBTF032110

Features : Touchscreen Graphic Display

Application : HumanMachine Interface for industrial automation

Phase : Other, Does not apply

Product Type : HumanMachine Interface

Power Supply : 24 V DC

Storage Temperature : 20C to 60C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry