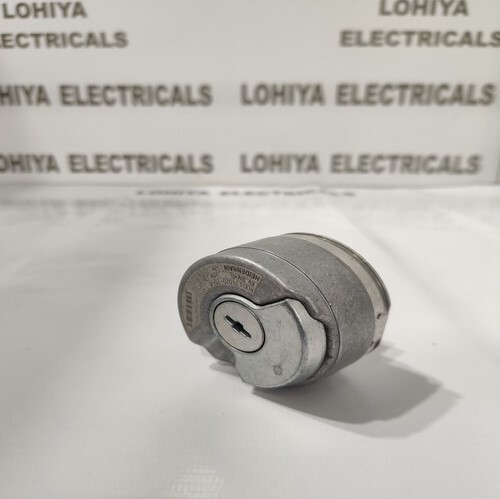

HEIDENHAIN ENCODER

HEIDENHAIN ENCODER Specification

- Current Rating

- 120 mA

- Cabinet Material

- Aluminum Housing

- Rated Operation Voltage

- 530 V DC (depending on model)

- Control System

- Digital Output

- Rated Current

- 120 mA

- Components

- Optical Sensor, Encoder Disk, Output Cable

- Cover Material

- ABS Plastic

- Operating Voltage

- 530 V DC

- Thickness

- Body Diameter Approx. 58 mm

- Way

- Incremental/Absolute

- Features

- High-resolution, Dustproof, Long Service Life

- Rated Insulation Voltage

- 500 V (testing)

- Cooling System

- Passive

- Protection Class

- Class III

- Connectivity Type

- Cable Output (Radial/Axial options)

- Protection Level

- IP64

- Base Material

- Aluminum Alloy

- Product Type

- Rotary Encoder

- Material

- Aluminum Alloy Housing, Stainless Steel Shaft

- Surface Finish

- Anodized

- Standard

- DIN EN 61010-1

- Surface Color

- Matte Silver and Black

- Rated Voltage

- 5 V DC10%

- Frequency (MHz)

- Up to 300 kHz Output Frequency

- Maximum Output Current

- 250 mA

- Dimension (L*W*H)

- 58 mm x 58 mm x 35 mm (excluding shaft)

- Application

- CNC Machines, Robotics, Automation, Motion Feedback.

- IP Rating

- IP64

- Output Signal Type

- TTL/HTL (Differential, RS422, Push-Pull options)

- Operating Temperature Range

- -20 C to +85 C

- Vibration Resistance

- 100 m/s (10-2000 Hz)

- Shock Resistance

- 1000 m/s, 6ms

- Resolution

- Up to 5000 PPR (Pulses Per Revolution)

- Bearing Life

- 100 x 10 revolutions minimum

- Mounting

- Clamping Flange

- Cable Length

- Standard 1 meter (custom on request)

- Model Name/Number

- ERN Series (e.g., ERN 1381, ERN 1387)

- Shaft Type

- Solid Shaft, 10 mm Diameter

- Weight

- Approx. 300g

- Storage Temperature

- -40 C to +100 C

About HEIDENHAIN ENCODER

Versatile Application, Remarkable Performance

The HEIDENHAIN ENCODER is suitable for CNC machinery, robotics, and diverse automation applications. Used for precise motion feedback, it guarantees accurate position and speed monitoring. Its key advantage lies in high-resolution sensing and robust construction, delivering long service life even under tough operational conditions. Its adaptability to both incremental and absolute feedback makes it an optimum solution for industrial control systems requiring reliability and efficiency.

Export Reach, Domestic Excellence & Streamlined Purchases

HEIDENHAIN ENCODERS are in high demand across major export markets in Europe, Asia, and North America, while also forming a backbone in the domestic automation sector. With efficient logistics, secure packaging, and flexible payment terms, businesses can plan their outlay confidently. Whether acquiring single units or bulk orders, transaction processes are streamlined for maximum convenience, ensuring timely delivery and reliable product support.

FAQs of HEIDENHAIN ENCODER:

Q: How do I select the correct HEIDENHAIN ENCODER model for my application?

A: Identify your operational requirements, including desired resolution (up to 5000 PPR), output signal type, shaft size, and environmental conditions. Consult the ERN Series specifications to match features like shaft diameter, protection level, and output options to your needs.Q: What are the main benefits of using the ERN Series encoder in automation systems?

A: The ERN Series delivers high-resolution feedback, robust vibration and shock resistance, and long bearing life. This ensures precise position tracking and reliability, which are vital in CNC machines, robotics, and other demanding automation environments.Q: Where is this encoder commonly used, and what applications benefit most?

A: HEIDENHAIN ENCODERS see frequent use in CNC machinery, robotics, and automated production lines, where position accuracy and durability are critical for operational efficiency and safety.Q: What kind of output signal types are available, and how do they integrate with control systems?

A: These encoders offer TTL/HTL (Differential, RS422, Push-Pull) outputs, ensuring compatibility with a wide range of digital controllers and motion feedback systems. Integration is straightforward via cable output (radial/axial).Q: How is the HEIDENHAIN ENCODER packaged and shipped to ensure safe delivery?

A: Encoders are packaged in secure, protective boxes tailored to withstand shocks and environmental exposure during transit, ensuring the product arrives safely and ready for installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HEIDENHAIN ENCODER Category

HEIDENHAIN ROD 431020-2048 ENCODER

Minimum Order Quantity : 1 Piece

Operating Voltage : 5 VDC

Application : Servo Motor Feedback, Robotics, CNC Machines

Surface Color : Other, Silver

Protection Level : Other, IP64

Product Type : Electric Panel

HEIDENHAIN ENCODER 736 080-51

Operating Voltage : 5 V DC

Application : CNC Machines, Robotics, Automation systems

Surface Color : Other, Silver

Protection Level : Other, IP64

Product Type : Other, Rotary Encoder

ENCODER EQN 1325.011-2048 E4

Operating Voltage : 5V DC

Application : Industrial Automation, CNC Machines

Surface Color : Other, Silver Gray

Protection Level : Other, IP 40

Product Type : Other, Rotary Encoder

HEIDENHAIN ENCODER ERN 1387.001

Operating Voltage : 5 V DC

Application : CNC machine tools, automation systems

Surface Color : Other, Silver and Black

Protection Level : Other, IP64

Product Type : Other, Rotary Encoder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry