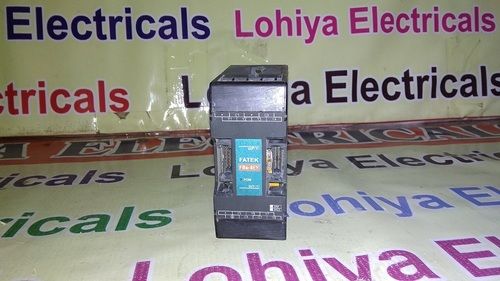

FATEK PLC

FATEK PLC Specification

- IP Rating

- IP20

- Phase

- Single Phase or Multi-phase (model dependent)

- Connectivity Type

- RS-232/RS-485, Ethernet (model dependent)

- Usage & Applications

- Factory Automation, Packaging Machines, Building Management

- Frequency

- 50/60 Hz

- Display

- Status LEDs

- Installation Type

- DIN Rail or Panel

- Mounting Type

- DIN Rail

- Output

- Relay Outputs: 6, Transistor Outputs: Optional

- Features

- Compact size, modular expansion, real-time processing, reliable performance

- Protection Level

- Basic surge and reverse polarity protection

- Current

- 0.5A (typical)

- Product Type

- Programmable Logic Controller (PLC)

- Operating Temperature

- 0C to 60C

- Working Temperature

- 0C to 60C

- Input

- Digital Inputs: 8, Analog Inputs: Optional via expansion modules

- Application

- Industrial Automation, Machine Control, Process Automation

- Supply Voltage

- 24V DC / 220V AC (model dependent)

- Accuracy

- High precision control, typically 0.1%

- Dimension (L*W*H)

- 90 mm x 70 mm x 60 mm (model dependent)

- Weight

- Approx. 350 g

- Programming Language

- Ladder Diagram (LD)

- Maximum Input Points

- Up to 256 Input Points (with expansions)

- Expansion Capability

- Supports Multiple I/O Modules

- Response Time

- 0.54µs (typical for 1 K-step logic instruction)

- Ambient Humidity

- 10% ~ 90% RH (non-condensing)

- Storage Temperature

- -20°C ~ 70°C

- Maximum Output Points

- Up to 256 Output Points (with expansions)

- Communication Protocols

- MODBUS, FATEK Protocol, Ethernet/IP (depends on module)

- Series

- FBs Series, B1/B1Z Series (model specific)

- Power Consumption

- Approx. 10W (varies by configuration)

- Memory

- Up to 32K steps program capacity (model dependent)

- Input Voltage Range

- 20.4V DC to 28.8V DC (for 24V DC models)

- Software Support

- WinProladder

About FATEK PLC

Versatile Applications & Competitive Edge

FATEK PLCs flourish in factory automation, process control, and building managementdelivering modular expansion for myriad applications. Surface of application includes packaging, industrial lines, and automation scenarios requiring high reliability. Their direction of use is streamlinedinstall on DIN rail or panel, connect I/O, and program via WinProladder. The competitive advantages are manifest: rapid logic response (0.54s), gilt-edged accuracy, robust modularity, and seamless integration into diverse automation networks.

Domestic Market & Packaging Excellence

FATEK PLCs are meticulously prepared for the main domestic markets, guaranteeing quick dispatch and secure handover to customers across the region. Sample policy supports evaluation before procurement, accommodating bespoke project needs. Packaging details highlight careful logistics planningunits arrive securely boxed with complete documentation, designed for swift installation and minimal downtime. Every process, from order to onsite delivery, prioritizes reliability, making FATEK PLCs ideal for time-sensitive automation solutions.

FAQs of FATEK PLC:

Q: How are FATEK PLCs customized for different automation needs?

A: FATEK PLCs offer modular expansion capabilities, enabling users to select and add I/O modules to match the precise requirements of their automation tasks or machine control applications.Q: What is the typical process to install a FATEK PLC system?

A: Installation involves mounting the PLC on a DIN rail or panel, connecting the appropriate I/O modules, establishing power and network connections, and configuring the system through WinProladder software.Q: Where can FATEK PLCs be used most effectively?

A: FATEK PLCs excel in diverse sectors, including factory automation, packaging machinery, and building management systems, thanks to their robust design and wide communication protocol support.Q: When should I consider expanding my FATEK PLC system?

A: Expansion is recommended when your automation project requires additional input or output points, or when new devices or subsystems are integrated into your control environment.Q: What benefits do FATEK PLCs provide over competitors?

A: FATEK PLCs bring rapid program response, gilt-edged accuracy, extensive communication options, and high reliability, making them an outstanding choice for precision automation and scalable control solutions.Q: How does FATEK PLC ensure operational reliability in harsh conditions?

A: FATEK PLCs are designed with solid protection features, operate within wide temperature and humidity ranges, and include surge and polarity safeguards to ensure uninterrupted performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FATEK MODULE CPU PLC HMI Category

FATEK MODULE

Current : 0.5A (max. output per point)

Input : Digital / Analog (model dependent)

Features : Hot swappable, modular design, remote I/O support

Application : Industrial automation, machine control

Output : Digital / Relay / Transistor (model dependent)

Protection Level : Other, Overload and shortcircuit protection

FATEK MODULE

Current : 0.5A

Input : 24V DC

Features : Compact design, reliable performance, expandability

Application : Industrial automation

Output : Relay/Transistor output (depending on module type)

Protection Level : Other, IP20

FATEK PLC

Current : 24V DC (Power Input), I/O current depending on model

Input : Digital and Analog Inputs (model dependent)

Features : Compact design, modular configuration, highspeed processing, flexible communication

Application : Industrial automation, machinery control, process control

Output : Digital and Analog Outputs (model dependent)

Protection Level : Other, Standard industrial

FATEK PLC

Current : 0.5A (typical)

Input : Digital/Analog

Features : Compact size, fast processing speed, flexible expansion modules

Application : Industrial automation, process control

Output : Relay/Transistor

Protection Level : Other, Short Circuit Protection, Overload Protection

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry