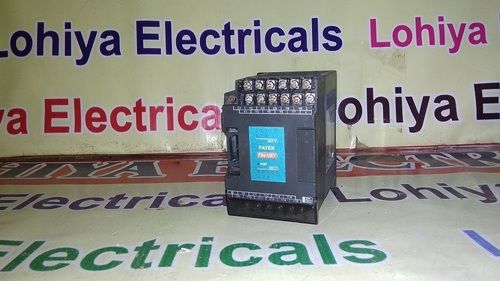

FATEK PLC

FATEK PLC Specification

- Installation Type

- DIN Rail or Panel Mount

- Connectivity Type

- RS232, RS485, Ethernet (optional modules)

- Display

- No integrated display, status indicators on module

- Output

- Digital and Analog Outputs (model dependent)

- Frequency

- 50/60 Hz

- Mounting Type

- DIN Rail, Panel Mount

- Protection Level

- Standard industrial

- IP Rating

- IP20

- Current

- 24V DC (Power Input), I/O current depending on model

- Usage & Applications

- Factory automation, process automation, machine control

- Phase

- Single Phase (Power Supply)

- Features

- Compact design, modular configuration, high-speed processing, flexible communication

- Measuring Range

- Model dependent

- Product Type

- FATEK PLC (Programmable Logic Controller)

- Operating Temperature

- 0C to 60C

- Working Temperature

- 0C to 60C

- Input

- Digital and Analog Inputs (model dependent)

- Application

- Industrial automation, machinery control, process control

- Supply Voltage

- AC 100-240V / DC 24V (model dependent)

- Accuracy

- High processing precision, model dependent

- Dimension (L*W*H)

- Model dependent, typically compact design

- Weight

- Model dependent

- Storage Temperature

- -25C to 70C

- Response Time

- <0.7 s/instruction (basic instruction)

- Expansion Capability

- Supports extension modules for I/O, communication, and special function cards

- Housing Material

- High-strength ABS plastic

- Indicator Lights

- LED status indicators for power and I/O

- Programming Language

- Ladder Diagram, Instruction List

- Communication Ports

- Built-in RS232/RS485, optional Ethernet communication

- Memory Capacity

- Program capacity up to 32K steps (model dependent)

- Ambient Humidity

- 20 to 95% RH (non-condensing)

About FATEK PLC

FATEK PLCUsage and Applications

The FATEK PLC is widely used for factory automation, machinery control, and process automation in industries seeking precision and adaptability. Utilized by system integrators, automation engineers, and manufacturers, this controller enables efficient management of complex industrial operations. With flexible mounting options and a compact design, the FATEK PLC is suited for both new installations and existing upgrades, ensuring seamless adaptation to various usage types.

Premium Domestic Market Offer and Delivery Process

FATEK PLC is offered with a commitment to premium customer experience across the domestic market. Shipment is efficiently managed through main ports including the preferred FOB port, ensuring prompt delivery times tailored to your project schedules. Customers receive dedicated support from order reservation to on-time dispatch, including flexible options to meet unique industrial requirements. Experience the advantage of a cost-effective and reliable automation solution supplied by expert traders.

FAQs of FATEK PLC:

Q: How does the FATEK PLC benefit industrial automation projects?

A: The FATEK PLC offers high-speed processing, flexible communication options, and modular expansion capabilities, allowing for seamless integration and precise control in factory automation, process control, and machine operation.Q: What programming languages can I use with the FATEK PLC?

A: FATEK PLC supports both Ladder Diagram and Instruction List programming languages, providing versatility for a range of industrial programming requirements.Q: When should I consider reserving the FATEK PLC for my facility?

A: You should reserve the FATEK PLC when upgrading existing automation systems, planning new installations, or requiring expandable, cost-effective controllers for process and machinery management.Q: Where is the FATEK PLC typically installed?

A: The FATEK PLC is commonly installed on DIN rails or panel mounts within control cabinets at manufacturing plants, process facilities, and other industrial environments.Q: What is the process for expanding the FATEK PLC system?

A: Expansion is straightforward. The controller supports extension modules for I/O, communication, and special functions, allowing users to scale the system as application demands increase.Q: What kind of support is offered for FATEK PLC shipment and delivery?

A: Customers are offered premium support, including shipment management, order tracking, and flexible delivery through main domestic ports, ensuring the PLC arrives promptly and in immaculate condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FATEK MODULE CPU PLC HMI Category

FATEK MODULE

Installation Type : DIN Rail Mounting

Product Type : PLC Expansion Module

Display : No builtin display

Dimension (L*W*H) : 90mm x 60mm x 82mm (varies by model)

Connectivity Type : Screw terminal, RS232/RS485 (optional)

Output : Digital / Relay / Transistor (model dependent)

FATEK MODULE

Installation Type : DIN Rail Mounting

Product Type : PLC Expansion Module

Display : LED Indicator

Dimension (L*W*H) : 90mm x 60mm x 76mm

Connectivity Type : Terminal Block

Output : Digital and Analog Outputs

FATEK PLC

Installation Type : DIN Rail Mounting

Product Type : PLC (Programmable Logic Controller)

Display : LED indicators

Dimension (L*W*H) : 90x90x45 mm approx. (varies by model)

Connectivity Type : RS232/RS485/USB

Output : Relay/Transistor

FATEK PLC

Installation Type : DIN Rail / Panel Mounting

Product Type : FATEK PLC (Programmable Logic Controller)

Display : LED/Status Indicator

Dimension (L*W*H) : 90mm x 60mm x 85mm (varies by model)

Connectivity Type : RS232 / RS485 Communication Ports

Output : Relay/Transistor Output

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry