Call:

DEMAG SERVO DRIVE

DEMAG SERVO DRIVE Specification

- Connector Type

- Screw Terminal / Push-in Connector

- Output Current

- 2A 180A

- Power Factor

- >0.95

- Rated Power

- As per drive model specification

- Working Temperature

- 0C to +55C

- Current Range

- 2A to 180A

- Operating Temperature

- 0C to +55C

- Power Supply

- AC Mains, 3-Phase

- Output Type

- Digital/Analog

- Features

- Compact design, High Control Accuracy, Integrated Fieldbus, Safe Torque Off (STO)

- Rated Current

- As per drive model specification

- Application

- Robotics, Automation, CNC Machines, Injection Molding

- Phase

- Three Phase

- Noise Level

- <65 dB

- Cooling Method

- Fan/Forced Air Cooling

- Product Type

- Servo Drive

- Output Power

- 0.5 kW - 90 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 200-480 V AC

- Voltage Protection

- Overvoltage/Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- Industrial Grade Metal Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Varies with model (approx. 7 kg - 35 kg)

About DEMAG SERVO DRIVE

Introducing the DEMAG SERVO DRIVE, a peerless solution engineered for world-class performance in automation, robotics, CNC, and injection molding. Enhanced with Vector Control/V/f control and supporting prominent communication interfaces like Profibus, EtherCAT, CANopen, and Modbus, it provides eminent efficiency up to 98%. Personalise your system with integrated alarm features, encoder inputs, and synchronization capabilities. Ending Soonexclusive Price Cut for Indian suppliers and traders. Rugged industrial-grade metal housing (IP20/IP54), mounted via panel, ensures reliable, safe operation in demanding settings. Firmware upgrades via USB/Serial, advanced voltage protection, and precise control offer a competitive edge.

Unrivaled Applications and Distinctive Advantages

The DEMAG SERVO DRIVE boasts a compact, robust design tailored for diverse surfaces of application, including robotics, CNC machines, and automated production systems. Enjoy competitive advantages like high control accuracy, fast synchronization, integrated fieldbus connectivity, and Safe Torque Off (STO). Extra features such as LED/LCD display panels, versatile mounting, superior line regulation, and embedded protection circuits ensure safety and efficiency, distinguishing DEMAG as a leader in industrial drive technology.

FOB Port, Supply Ability, and Domestic Market Excellence

Our supply chain supports prompt DEMAG SERVO DRIVE order processing via designated Indian FOB ports. With substantial supply ability and reliable logistics, we cater to proposals of various expenditure and project scale. The main domestic market, backed by efficient distribution and tailored support, ensures customers experience expedited delivery and seamless procurement from proposal amount to final order fulfillment.

Unrivaled Applications and Distinctive Advantages

The DEMAG SERVO DRIVE boasts a compact, robust design tailored for diverse surfaces of application, including robotics, CNC machines, and automated production systems. Enjoy competitive advantages like high control accuracy, fast synchronization, integrated fieldbus connectivity, and Safe Torque Off (STO). Extra features such as LED/LCD display panels, versatile mounting, superior line regulation, and embedded protection circuits ensure safety and efficiency, distinguishing DEMAG as a leader in industrial drive technology.

FOB Port, Supply Ability, and Domestic Market Excellence

Our supply chain supports prompt DEMAG SERVO DRIVE order processing via designated Indian FOB ports. With substantial supply ability and reliable logistics, we cater to proposals of various expenditure and project scale. The main domestic market, backed by efficient distribution and tailored support, ensures customers experience expedited delivery and seamless procurement from proposal amount to final order fulfillment.

FAQs of DEMAG SERVO DRIVE:

Q: How does the DEMAG SERVO DRIVE benefit industrial automation applications?

A: The DEMAG SERVO DRIVE delivers precise control, high efficiency, and reliable synchronization, making it ideal for robotics, CNC, and automation systems where accuracy and performance are paramount.Q: What communication interfaces are supported by the DEMAG SERVO DRIVE?

A: It supports multiple world-class communication protocols, including Profibus, EtherCAT, CANopen, and Modbus, enabling seamless integration into existing automation and control networks.Q: When should the braking unit and encoder inputs be selected?

A: These features should be chosen based on specific model requirements and application needs, particularly if enhanced stopping control or precise positional feedback is necessary for your process.Q: Where can the DEMAG SERVO DRIVE be installed?

A: The drive supports panel mounting and is suitable for industrial environments with IP20 or IP54 protection, depending on the selected model, offering flexibility for installation in diverse applications.Q: What is the process for upgrading DEMAG SERVO DRIVE firmware?

A: Firmware upgrades are straightforward and can be performed via USB or serial interfaces, ensuring the drive remains up-to-date with the latest control enhancements and security features.Q: How does the integrated alarm function enhance safety?

A: The built-in alarm system provides instant alerts for overcurrent, overheating, or short circuit events, allowing prompt action to prevent system damage and ensure consistent operational safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in DEMAG SERVO DRIVE Category

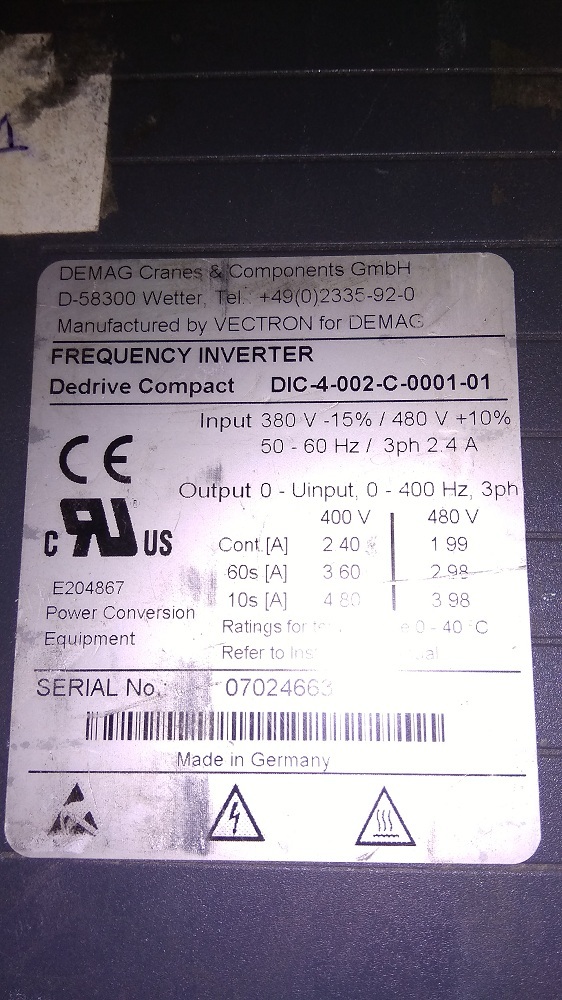

DEMAG DIC-4-002-C-0003-01 FREQUENCY INVERTER DRIVES

Minimum Order Quantity : 1 Piece

Efficiency : Up to 98%

Output Type : Other, Adjustable AC Output

Storage Temperature : 25C to +65C

Power Supply : ThreePhase AC

DEMAG DIC-4-004-E-0000-03 FREQUENCY INVERTER DRIVE

Minimum Order Quantity : 1 Piece

Efficiency : 98%

Output Type : Other, Threephase

Storage Temperature : 25C to +70C

Power Supply : AC supply, 3phase

DEMAG SERVO DRIVE

Efficiency : >95%

Output Type : Other, Threephase Output

Storage Temperature : 25C to +70C

Power Supply : AC Supply

DEMAG SERVO DRIVE

Efficiency : Above 95%

Output Type : Other, ThreePhase

Storage Temperature : 20C to 70C

Power Supply : AC Power

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry