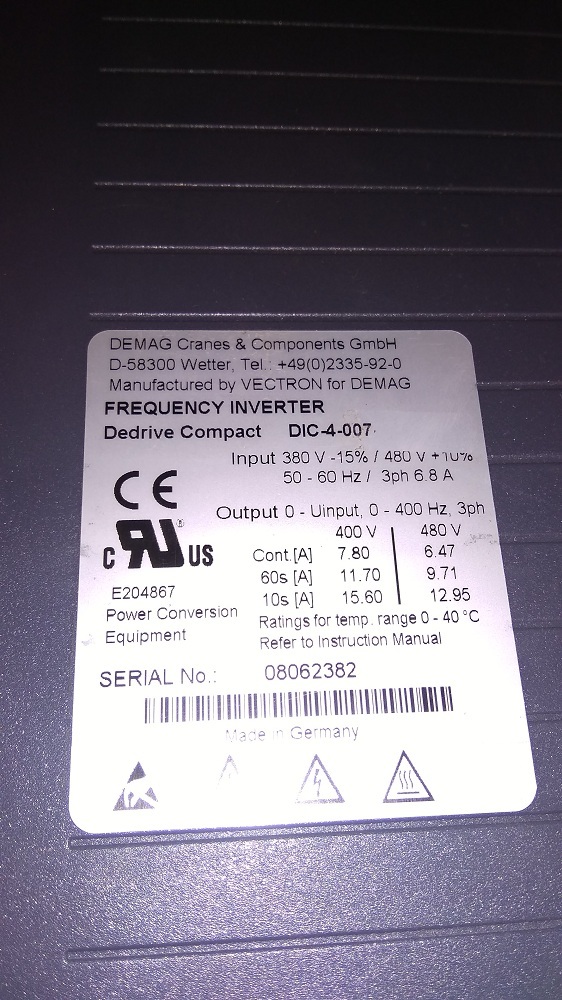

DEMAG SERVO DRIVE

DEMAG SERVO DRIVE Specification

- Current Range

- 0 - 10A

- Application

- Industrial Automation, CNC, Robotics, Injection Molding Machines

- Cooling Method

- Forced Air Cooling / Built-in Fan

- Working Temperature

- 0C to +55C

- Noise Level

- <65 dB(A)

- Power Supply

- AC Supply

- Phase

- Three Phase

- Rated Power

- 2.5 kW

- Operating Temperature

- 0C to +55C

- Features

- High Precision, Compact Design, Programmable, Fault Diagnosis

- Rated Current

- 6.7 A

- Power Factor

- >0.98

- Output Type

- Three-phase Output

- Output Current

- 6.7 A

- Connector Type

- Screw Terminals & Industrial Connector

- Product Type

- DEMAG SERVO DRIVE

- Output Power

- 2.5 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 220-480V AC, 50/60Hz

- Voltage Protection

- Over-voltage & Under-voltage Protection

- Efficiency

- >95%

- Material

- Metal Alloy / Industrial Grade Plastic

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 6.5 kg

About DEMAG SERVO DRIVE

Competitive Advantages & Application Versatility

The DEMAG SERVO DRIVE sets itself apart with high precision, compact design, and programmable functionality, making it a powerhouse for industrial automation. Its performance excels in CNC operations, robotics, and injection molding machines. With versatile mounting options and user-friendly diagnostic display, its an optimal fit for control panels in factories or industrial sites. Enhanced features like integrated brake chopper and forced air cooling ensure longevity and reliable operation, even in high-demand environments.

Global Export Value & Order Processing

Renowned for its exceptional market value, the DEMAG SERVO DRIVE is a prominent choice in global markets including Asia, Europe, and North America. Suppliers and traders in India offer secure order processing through recognized FOB ports, supporting smooth exchange and transaction experience. Samples are available for qualified inquiries, streamlining your evaluation process before bulk commitments. High reliability in both design and logistics has driven consistent international demand and favorable exchange outcomes across top export destinations.

FAQs of DEMAG SERVO DRIVE:

Q: How does the DEMAG SERVO DRIVE ensure high precision in demanding industrial applications?

A: The DEMAG SERVO DRIVE utilizes advanced Vector Control and V/f Control methods, paired with incremental or absolute encoder feedback, delivering robust precision and rapid response (<2 ms) for CNC, robotics, and automation tasks.Q: What protection features are built into the DEMAG SERVO DRIVE to ensure safe operation?

A: It comes equipped with short circuit, overload, overheat, earth fault, over-voltage, and under-voltage protection, ensuring reliable and safe usage in industrial environments.Q: When should I consider using the DEMAG SERVO DRIVE for my machinery upgrades?

A: This servo drive is ideal for replacing or upgrading existing drives in high-demand machinery such as CNC, industrial automation equipment, robotics, and injection molding machines, especially if high efficiency and precision are critical.Q: Where can the DEMAG SERVO DRIVE be installed?

A: The drive is designed for panel mount or DIN rail mount installations, making it suitable for factory control panels and industrial enclosures.Q: What is the process for upgrading the firmware on the DEMAG SERVO DRIVE?

A: Firmware upgrades are supported via its integrated communication ports (RS232, CANopen, Profibus), allowing for straightforward updates without removing the drive from its installation.Q: What are the primary benefits of choosing the DEMAG SERVO DRIVE over other drives?

A: Key benefits include ultra-fast response time, exceptional efficiency (>95%), integrated diagnostic/fault analysis, versatile communication options, compact design, and seamless operation in high-humidity or challenging conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DEMAG SERVO DRIVE Category

DEMAG DIC-4-002-C-0003-01 FREQUENCY INVERTER DRIVES

Minimum Order Quantity : 1 Piece

Input Voltage : 400 V AC

Working Temperature : 10C to +50C

Voltage Protection : Overvoltage and Undervoltage Protection

Cooling Method : Forced Air Cooling

Application : Hoist and Crane Automation, Motor Speed Control, Industrial Automation

DEMAG DIC-4-002-C-0000-00 FREQUENCY INVERTER DRIVE

Minimum Order Quantity : 1 Piece

Input Voltage : 380480 V AC

Working Temperature : 10C to +50C

Voltage Protection : Over Voltage, Under Voltage Protection

Cooling Method : Forced Air Cooling

Application : Industrial Automation, Crane Drives

DEMAG SERVO DRIVE

Input Voltage : 3 x 400 V AC

Working Temperature : 0C to +55C

Voltage Protection : Integrated overvoltage and undervoltage protection

Cooling Method : Forced air cooling

Application : Industrial automation, injection molding, robotics

DEMAG SERVO DRIVE

Input Voltage : 3 x 400 V AC

Working Temperature : 0C to +50C

Voltage Protection : Overvoltage and Undervoltage Protection

Cooling Method : Forced Air Cooling

Application : Industrial Automation, Injection Molding Machines

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry