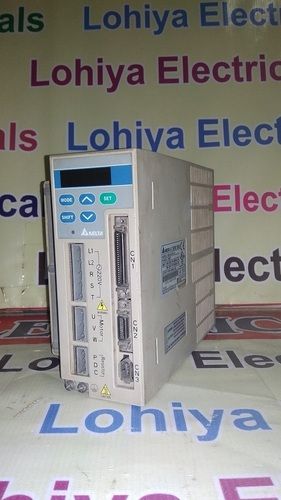

DELTA SERVO DRIVE

DELTA SERVO DRIVE Specification

- Application

- Industrial Automation, CNC Machines, Packaging, Robotics

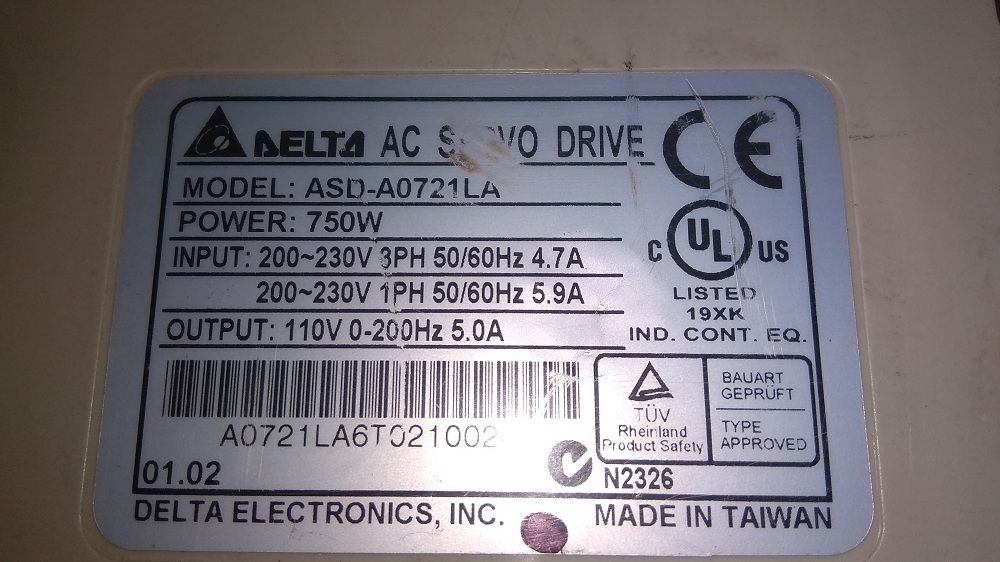

- Rated Current

- 3.0 A

- Connector Type

- Screw Terminal

- Features

- Compact Design, High Responsiveness, Auto Tuning Function, Built-In Position, Speed and Torque Controls

- Noise Level

- <55 dB

- Rated Power

- 0.75 kW

- Working Temperature

- 0C to +55C

- Phase

- Single Phase / Three Phase

- Current Range

- 0-10A

- Power Supply

- AC Power

- Power Factor

- >0.95

- Output Current

- 3.0A

- Cooling Method

- Forced Air Cooling

- Output Type

- Digital / Analog

- Operating Temperature

- 0C to +55C

- Product Type

- Servo Drive

- Output Power

- 750 W

- Output Frequency

- 0-400 Hz

- Input Voltage

- 200-230 VAC

- Voltage Protection

- Overvoltage, Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- ABS & Metal

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to +65C

- Weight

- Approx 1.1 kg

- Feedback

- Incremental Encoder Interface

- Vibration Resistance

- 10 to 55 Hz (Double Amplitude 1.5 mm)

- Mounting Type

- Panel Mount

- Environmental Compliance

- RoHS

- Display Type

- LED Digital Display

- Insulation Resistance

- 50 M (500 VDC)

- Communication Ports

- RS-232/RS-485/Modbus

- Protection Class

- IP20

- Frequency Response

- Up to 1 kHz

- Max Motor Capacity

- Up to 750 W

- Control Mode

- Position, Speed, Torque Control

- Model Number

- ASD Series

About DELTA SERVO DRIVE

Direction, Application & Durability of DELTA SERVO DRIVE

Install the DELTA SERVO DRIVE with a simple panel mount on any applicable industrial surface, ensuring secure and stable operation. Designed with a blend of ABS and metal, it ensures robust durability and long-lasting performance. The drive perfectly suits surfaces within CNC machines, packaging lines, and robotic workspaces, marrying pristine build quality with advanced function. Its auto-tuning and built-in controls streamline setup, allowing for smooth integration into automated industrial environments.

Domestic Market Coverage, Availability & Timely Delivery

DELTA SERVO DRIVE dominates the domestic mar with widespread presence, meeting the dynamic needs of various industries efficiently. With stock ready for immediate dispatch, clients minimize expenditure on downtime. Our supply ability ensures consistent product flow, and we pride ourselves on sharply reduced delivery times. Whether your business requires a single drive or large-scale procurement, our logistics guarantee reliability and prompt response across all regions.

FAQs of DELTA SERVO DRIVE:

Q: How does the DELTA SERVO DRIVE support different control modes?

A: The DELTA SERVO DRIVE ASD Series is equipped to offer three primary control modes: Position, Speed, and Torque Control. This versatility allows users to tailor the drives performance for a variety of industrial automation, packaging, and robotics applications, optimizing operational output.Q: What are the main benefits of using the DELTA SERVO DRIVE in automated systems?

A: Key benefits include high efficiency up to 98%, rapid frequency response up to 1 kHz, auto tuning function for ease of setup, and built-in protection features such as overvoltage and undervoltage safeguards. These attributes ensure precise, stable, and energy-efficient operation.Q: Where can the DELTA SERVO DRIVE be mounted and what surfaces are suitable?

A: The drive is designed for panel mount applications, making it ideal for installation within control cabinets, industrial panels, and machinery enclosures found in CNC machines, packaging equipment, and robotic systems.Q: What is the process for integrating the DELTA SERVO DRIVE into an industrial system?

A: Integration involves mounting the drive securely on a panel, connecting to the desired incremental encoder for feedback, configuring input voltages (200-230 VAC), and utilizing the LED digital display along with the auto tuning feature for precise setup.Q: When can customers expect delivery of the DELTA SERVO DRIVE for domestic orders?

A: With stock ready and a robust supply network, the DELTA SERVO DRIVE is typically delivered within a few business days, ensuring minimal downtime and swift deployment for industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DELTA Used PLC HMI AC DRIVE Category

DELTA PLC

Power Supply : 24V DC

Product Type : Programmable Logic Controller (PLC)

Working Temperature : 0C to 55C

Efficiency : High (typically above 80%)

Phase : Single Phase

Noise Level : Low, <50 dB

DELTA SERVO DRIVE

Power Supply : AC Power Supply

Product Type : DELTA Servo Drive

Working Temperature : 0C to 55C

Efficiency : Approx. 95%

Phase : Other, 1phase / 3phase

Noise Level : 50 dB

Delta VFD007M43B

Power Supply : AC

Product Type : Variable Frequency Drive

Working Temperature : 10C to 50C

Efficiency : High Efficiency

Phase : Other, Threephase

Noise Level : Low

DELTA SERVO DRIVE

Power Supply : AC Power

Product Type : Servo Drive

Working Temperature : 0C to +55C

Efficiency : High (Typically > 90%)

Phase : Other, 1Phase / 3Phase

Noise Level : Low (<60 dB)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry