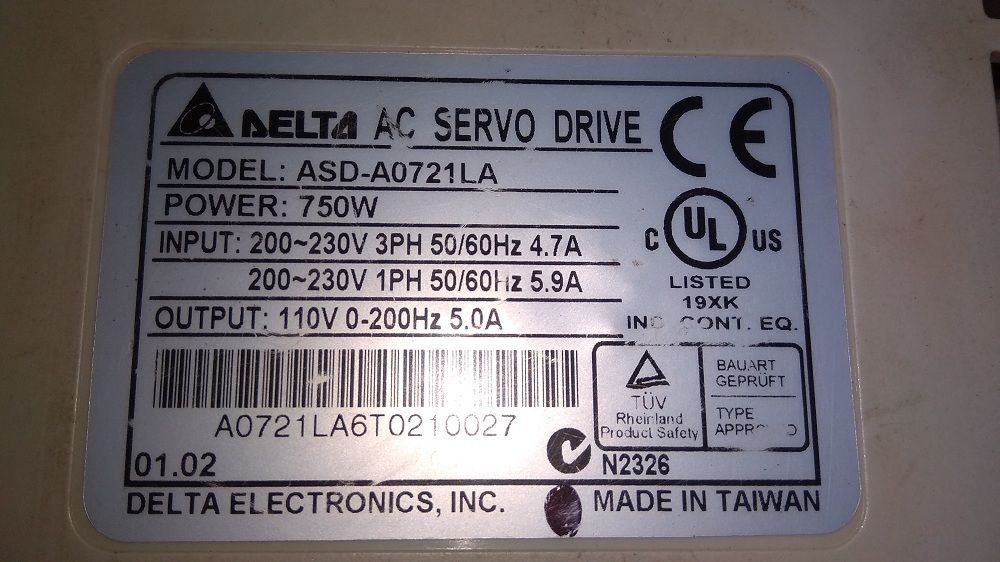

DELTA SERVO DRIVE

DELTA SERVO DRIVE Specification

- Rated Current

- 2.8 A

- Noise Level

- <55 dB

- Application

- CNC, Robotics, Automation, Packaging Machinery

- Power Factor

- >0.9

- Operating Temperature

- 0C to 55C

- Current Range

- 0-3 A

- Working Temperature

- 0C to 55C

- Output Type

- Three Phase

- Connector Type

- Screw Terminal

- Phase

- Single / Three Phase

- Features

- Compact Design, Digital Display, Auto Tuning, High-speed Response

- Output Current

- 2.8 A

- Power Supply

- AC 200-240V

- Cooling Method

- Forced Air Cooling

- Rated Power

- 400 W

- Product Type

- Delta Servo Drive

- Output Power

- 400 W

- Output Frequency

- 0-400 Hz

- Input Voltage

- 220 V AC, Single Phase

- Voltage Protection

- Over-voltage / Under-voltage / Short Circuit

- Efficiency

- Up to 95%

- Material

- Industrial Grade Plastic, Metal Enclosure

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 65C

- Weight

- 1.2 kg

- Mounting Type

- Panel Mounting

- Encoder Feedback

- Incremental / Absolute Encoder Supported

- Display

- LED Digital Display

- Alarm Output

- Relay Output

- Communication Interface

- RS-232 / RS-485 / CANopen

- Motor Type Compatibility

- AC Servo Motor

- Insulation Resistance

- >=20 M (500V DC)

- Braking Function

- Integrated Dynamic Braking

- Dielectric Strength

- 1.5 kV, 1 min

- Protection Rating

- IP20

- Relative Humidity

- 5%-95% (non-condensing)

- Control Mode

- Position / Speed / Torque Control

- Maximum Pulse Input Frequency

- 4 MHz

- Start/Stop Method

- Digital/Analog Input, Communication

About DELTA SERVO DRIVE

Versatile Usage and Advanced Features for Industrial Plants

The DELTA SERVO DRIVE is expertly designed for demanding industrial plants and automation lines, excelling in tasks such as CNC machining, robotics, and packaging machinery. Its cutting-edge features include multiple control modes, integrated dynamic braking, a digital display for real-time monitoring, and support for both incremental and absolute encoders. This compact device ensures swift, precise motion control, making it an ideal choice for plant engineers seeking reliability, productivity, and adaptability in their automated systems.

Packaging, Payment & Exchange for Export Markets

Each DELTA SERVO DRIVE is securely packaged for export, ensuring safe dispatch and intact delivery. Payment terms are transparent and customer-friendly, including standard exchange options and flexible processing for bulk orders. Sample policies are available upon request, allowing buyers to evaluate the product before making volume commitments. We promptly dispatch orders to meet your operational timeline and streamline transactions for global and domestic markets, fostering trust and convenience with every shipment.

FAQs of DELTA SERVO DRIVE:

Q: How do I use the DELTA SERVO DRIVE for different types of motor control?

A: The DELTA SERVO DRIVE supports Position, Speed, and Torque Control modes, selectable according to your application requirements. You can configure these modes via digital/analog inputs or through communication interfaces such as RS-232, RS-485, or CANopen.Q: What are the key benefits of using the DELTA SERVO DRIVE in robotics and CNC applications?

A: With its high-speed response, auto-tuning capabilities, and precise control, the DELTA SERVO DRIVE ensures enhanced accuracy and efficiency in robotics and CNC environments, minimizing downtime and optimizing machine performance.Q: When should I consider using the integrated dynamic braking function?

A: Integrated dynamic braking is ideal during rapid stop or emergency procedures, especially in high-inertia or high-speed applications, ensuring your equipment halts safely and prevents mechanical damage.Q: Where is the DELTA SERVO DRIVE typically installed in automation systems?

A: This servo drive is designed for panel mounting, making it suitable for integration in control cabinets commonly used in plant automation, packaging lines, and robotic cells.Q: What is the process for exchanging or obtaining a sample unit for export markets?

A: For export clients, sample policies facilitate evaluation before bulk purchase. Once your order or exchange request is processed, the product is securely packaged and dispatched promptly, ensuring efficient international delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DELTA Used PLC HMI AC DRIVE Category

DELTA POWER SUPPLY

Operating Temperature : 0C to 50C

Product Type : Switching Power Supply

Storage Temperature : 20C to 85C

Material : Aluminum Alloy

Input Voltage : 85V 264V AC

Application : Industrial Automation

DELTA PLC

Operating Temperature : 0C to 55C

Product Type : Programmable Logic Controller (PLC)

Storage Temperature : 25C to +70C

Material : Industrial Grade Plastic/Metal Enclosure

Input Voltage : 24V DC

Application : Industrial Automation, Machinery Control, Process Control

ALLEN BRADLEY PLC

Operating Temperature : 0C to 60C

Product Type : Programmable Logic Controller (PLC)

Storage Temperature : 40C to +85C

Material : Industrial grade Polycarbonate & Metal

Input Voltage : 24V DC or 100240V AC (varies by model)

Application : Industrial automation, machine control, process control

DELTA KJ1501X1-BA2 POWER SUPPLY

Operating Temperature : 20C to +70C

Product Type : Power Supply Unit

Storage Temperature : 40C to +85C

Material : Metal Housing

Input Voltage : 100240VAC, 2.5A, 50/60Hz

Application : Industrial Automation, Control Panels

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry