ALLEN BRADLEY PLC

ALLEN BRADLEY PLC Specification

- Current Range

- Analog: 0-20mA, Digital: up to 2A

- Application

- Industrial automation, machine control, process control

- Output Type

- Relay, transistor or analog output (depending on model)

- Cooling Method

- Natural air cooling

- Rated Power

- 8-16W per module

- Power Supply

- External supply required (see input voltage)

- Power Factor

- >0.9

- Working Temperature

- 0C to 60C

- Operating Temperature

- 0C to 60C

- Phase

- Single-phase/Three-phase (module dependent)

- Connector Type

- Screw terminal, plug-in terminal blocks

- Features

- Modular design, expansion slots, LED indicators, DIN rail mountable

- Output Current

- Max 2A/channel (digital), 0-20mA (analog)

- Noise Level

- Low, <60 dB

- Rated Current

- 0.5-2A (per output channel)

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- Depends on module, typically 8-16W

- Output Frequency

- DC or up to 60 Hz (module dependent)

- Input Voltage

- 24V DC or 100-240V AC (varies by model)

- Voltage Protection

- Overvoltage and short-circuit protection integrated

- Efficiency

- Typically >85%

- Material

- Industrial grade Polycarbonate & Metal

- Line Regulation

- <1% typ.

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 400-800g (module dependent)

- Analog Output Channels

- 2/4 channel modules available

- Scan Time

- Approx. 0.1 ms/k instruction

- Protection Level

- IP20/IP21 (model dependent)

- Digital Output Channels

- 8/16/32 channel modules available

- Communication Protocols

- Ethernet/IP, DeviceNet, Modbus, RS232/RS485, optional communication modules

- Digital Input Channels

- 8/16/32 channel modules available

- Analog Input Channels

- 2/4/8 channel modules available

- Mounting Type

- DIN rail

- Display

- Status LEDs, optional HMI

- Expandability

- Supports multiple I/O and communication modules

- Program Memory

- Typically 2MB to 8MB (model dependent)

- Minimum Order Quantity

- 1 piece

- Software Support

- RSLogix 500, Studio 5000, compatible programming tools

About ALLEN BRADLEY PLC

Superior Performance and Versatility for Every Industry

The ALLEN BRADLEY PLC stands out due to its primary competitive advantages: scalable architecture, modular expansion, and a matchless suite of communication protocols. This controller excels in application places such as manufacturing plants, processing facilities, and OEM machinery. Its application method is straightforwardsimply mount on a DIN rail, configure digital or analog modules, and connect via standardized terminal blocks, allowing reliable automation tailored for diverse industrial requirements.

Optimized Supply Chain and Streamlined Procurement

Our supply ability ensures continuous availability to meet varied client needs, reducing your expenditure on downtime. The PLC is available from just one piece, with flexible sample policies to simplify your procurement process. Expedite your shipment with minimal charge, often within days of your order. Thanks to our robust logistics network, delivery time is minimized, ensuring you swiftly receive the ALLEN BRADLEY PLC to advance your automation strategy.

FAQs of ALLEN BRADLEY PLC:

Q: How do I select the right ALLEN BRADLEY PLC configuration for my application?

A: Begin by evaluating your control requirementsconsider the number of input/output channels, desired communication protocols, expansion needs, and environmental factors. Consult technical datasheets or our specialists to match the optimal model and module combination.Q: What communication protocols are supported by this PLC?

A: The ALLEN BRADLEY PLC supports multiple protocols including Ethernet/IP, DeviceNet, Modbus, RS232/RS485, and can be expanded with optional communication modules for broader network compatibility.Q: Where is the ALLEN BRADLEY PLC commonly used?

A: This PLC is widely implemented across industrial automation, machine control, and process control in manufacturing, assembly lines, and processing plants requiring reliable, scalable, and modular automation solutions.Q: What are the main benefits of using this PLC in my facility?

A: Benefits include robust protection features, seamless integration with major programming tools, high efficiency, modular expandability, and a small form factorresulting in minimized downtime and enhanced process control.Q: How does the delivery and sample procurement process work?

A: You may order as few as one piece and request samples according to our sample policy. Upon order confirmation, shipment charges are calculated and delivery is scheduled rapidly, minimizing wait times throughout the procurement process.Q: What is required for installation and initial usage?

A: Installation is straightforward: mount the PLC on a DIN rail, connect all modules using screw terminals or plug-in terminal blocks, and power up with the recommended input voltage. Program the system using RSLogix 500 or Studio 5000 before commissioning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

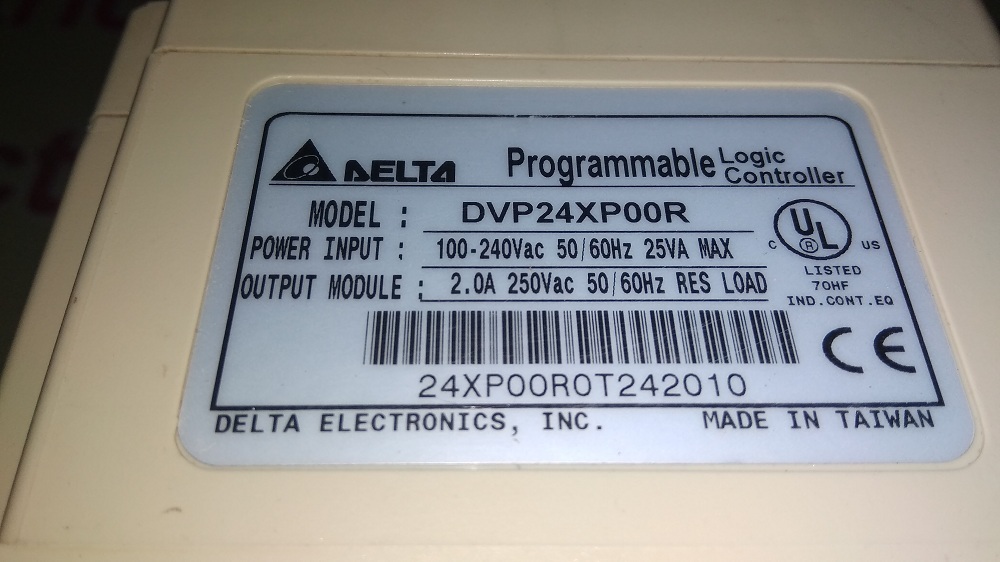

More Products in DELTA Used PLC HMI AC DRIVE Category

DELTA HMI

Features : Multilanguage support, TFT Display, Touch Panel, Communications Ports (RS232/RS485/Ethernet)

Connector Type : Terminal Block, Ethernet Port, Serial Port

Noise Level : Silent Operation

Voltage Protection : Overvoltage/Undervoltage Protection

Working Temperature : 0C to 50C

DELTA POWER SUPPLY DELTA 77-964-4300

Features : Compact design reliable performance

Connector Type : Standard Connectors

Line Regulation : 1%

Noise Level : Low

Voltage Protection : Overvoltage protection

Working Temperature : 0C to 40C

DELTA CPU DVP16SP11T

Features : 16 I/O Points, HighSpeed Counter, Expandable, Communication Port

Connector Type : Screw Terminal

Line Regulation : 0.1% max

Noise Level : Low

Voltage Protection : Overvoltage/Undervoltage Protection

Working Temperature : 0C ~ 55C

Delta VFD-B

Features : Programmable Multifunction keypad Builtin EMI Filter

Connector Type : Terminal Block

Line Regulation : Excellent

Noise Level : Low

Voltage Protection : Overvoltage Protection

Working Temperature : 10C to 50C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry