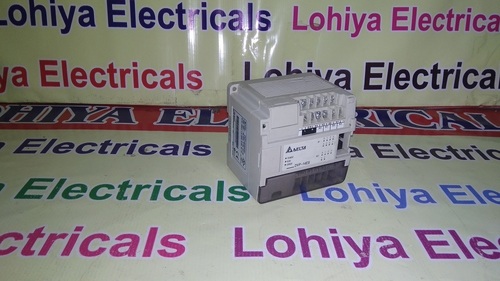

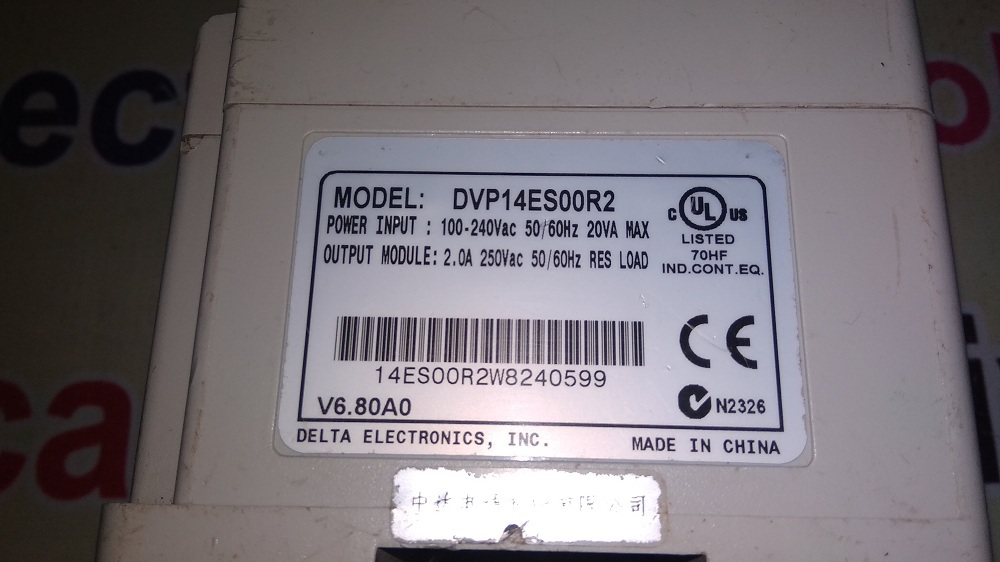

DELTA PLC

DELTA PLC Specification

- Features

- Compact Design, High-Speed Processing, User-Friendly Programming, LED Indicators, Expandable Modules

- Cooling Method

- Natural Air Cooling

- Application

- Industrial Automation, Process Control, Machine Automation

- Operating Temperature

- 0C to 55C

- Output Current

- 1A per output channel

- Power Factor

- >0.9

- Rated Power

- 10W - 30W (model dependent)

- Current Range

- 0.1A to 1A (per output)

- Noise Level

- Low, <40dB

- Working Temperature

- 0C to 55C

- Connector Type

- Screw Terminal

- Rated Current

- 1A (per output)

- Phase

- Single Phase

- Power Supply

- 24V DC

- Output Type

- Relay/Transistor

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- 24V DC (Relay output capacity 1A at 24V)

- Output Frequency

- 50/60Hz

- Input Voltage

- 24V DC

- Voltage Protection

- Overvoltage, Surge Protection

- Efficiency

- High (factory standard)

- Material

- Industrial Grade Plastic/Metal Housing

- Line Regulation

- 1%

- Storage Temperature

- -20C to +70C

- Weight

- Approx. 250g

About DELTA PLC

DELTA PLC: Versatile Application Areas and Industrial Suitability

DELTA PLC excels in a broad sweep of application areas, from industrial automation to process and machine control. Used as a central control unit in manufacturing, it integrates seamlessly with complex systems to orchestrate efficient operations. This PLC is suitable for use in packaging, production lines, and automated processing plants. Its robust design and adaptability make it an ideal choice for OEMs, panel builders, and process industries needing reliable and scalable control solutions.

Robust Export Markets & Streamlined Packing and Dispatch

The DELTA PLC ranges are rated highly across major export markets, including Southeast Asia, the Middle East, Europe, and Africa. With a formidable supply ability to meet large demands, we ensure edge-to-edge service from packing to shipped goods. Orders are processed swiftly and efficiently, with goods packed securely for dispatch. Shipments are typically FOB from prominent international ports, enabling timely deliveries that meet global industrial automation requirements.

FAQs of DELTA PLC:

Q: How does the DELTA PLC ensure reliable protection during industrial operations?

A: The DELTA PLC offers comprehensive protection, including overvoltage and surge protection, safeguarding both the PLC and connected devices. With its IP20-rated enclosure and industrial-grade housing, it withstands harsh environments, minimizing downtime and errors.Q: What are the main benefits of the DVP Series expandable modules?

A: The DVP Series supports expansion up to 16 modules, allowing users to scale system capabilities as requirements grow. This supports flexibility for future upgrades, broader I/O support, and integration of additional process controls, maximizing investment value.Q: Where can DELTA PLCs be used for best performance?

A: DELTA PLCs are best utilized in industrial automation, process control, and machine operation settings, including factory lines, packaging machines, and batch processing plants. Their robust design suits demanding, round-the-clock environments.Q: How simple is the programming process with DELTA PLC?

A: Programming is user-friendly, as the DELTA PLC supports widely recognized Ladder Logic and Function Block Diagram (FBD) languages. This allows engineers and operators to build, modify, and troubleshoot control sequences with ease.Q: What input voltages does the DELTA PLC accept and how is input type selected?

A: The DELTA PLC models accept 12/24V DC digital inputs with sink/source selectable options. This flexibility ensures compatibility with varied sensors and switches used in modern automation systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DELTA Used PLC HMI AC DRIVE Category

DELTA HMI

Features : Multilanguage support, TFT Display, Touch Panel, Communications Ports (RS232/RS485/Ethernet)

Operating Temperature : 0C to 50C

Application : Industrial Automation, Process Control, Factory Equipment

Cooling Method : Natural Air Cooling

Storage Temperature : 20C to 60C

Efficiency : Approx. 85%

DELTA SERVO DRIVE

Features : High precision, fast response, overload protection, compact design

Operating Temperature : 0C to 55C

Application : Industrial automation, CNC machines, robotics

Cooling Method : Forced air cooling

Storage Temperature : 20C to 65C

Efficiency : Up to 95%

DELTA SERVO DRIVE

Features : Compact Design, High Responsiveness, Auto Tuning Function, BuiltIn Position, Speed and Torque Controls

Operating Temperature : 0C to +55C

Application : Industrial Automation, CNC Machines, Packaging, Robotics

Cooling Method : Forced Air Cooling

Storage Temperature : 20C to +65C

Efficiency : Up to 98%

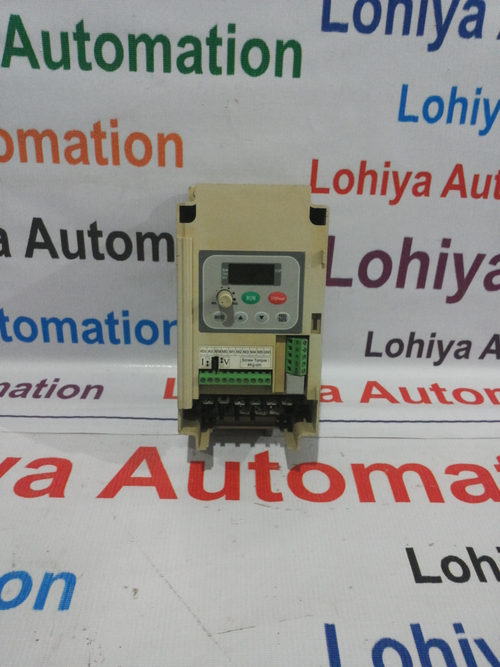

Delta VFD015S43D

Features : Compact design Easy installation and operation

Operating Temperature : 0C to 50C

Application : Industrial Automation

Cooling Method : Natural Cooling

Storage Temperature : 20C to +60C

Efficiency : High Efficiency

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry