BOSCH SERVO DRIVE

BOSCH SERVO DRIVE Specification

- Phase

- Three Phase

- Application

- Automated Machinery, Robotics, CNC Machines, Packaging Equipment

- Features

- High dynamic response, Built-in diagnostics, Parameter storage, Safe Torque Off (STO)

- Output Type

- Digital/Analog

- Rated Current

- 5.2 A

- Power Factor

- >0.98

- Power Supply

- AC 3x 400V/480V

- Noise Level

- <60 dB

- Current Range

- 0-6 A

- Cooling Method

- Forced Air Cooling

- Output Current

- 5.2 A

- Operating Temperature

- 0C to +55C

- Rated Power

- 2.5 kW

- Connector Type

- Terminal Block, Plug-in Connector

- Working Temperature

- 0C to +55C

- Product Type

- Bosch Servo Drive

- Output Power

- 2.5 kW

- Output Frequency

- 0-600 Hz

- Input Voltage

- 380-480 V AC 3-phase

- Voltage Protection

- Overvoltage, Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- Industrial Grade Aluminium Housing

- Line Regulation

- <0.5%

- Storage Temperature

- -25C to +70C

- Weight

- 5.8 kg

- Display

- LED and LCD Display

- Protection Class

- IP20

- Control Method

- Field Oriented Control (FOC), V/f Control

- Ambient Humidity

- 5%95% non-condensing

- Supported Motor Types

- Synchronous, Asynchronous, Servo Motors

- Firmware Upgrade

- Yes, via USB or Network

- Braking Unit

- Integrated

- Mounting Type

- Panel Mount

- Communication Interface

- EtherCAT, CANopen, Profibus, Modbus

- Maximum Output Voltage

- 530 V AC

About BOSCH SERVO DRIVE

Versatile Applications in Diverse Industries

The BOSCH SERVO DRIVE stands as a premier choice in plant applications spanning automated machinery, sophisticated robotics, CNC systems, and advanced packaging equipment. It is widely used as a central drive controller by manufacturers aiming for precision and high-yield operations. Plant engineers, automation specialists, and OEMs consistently choose this solution for its reliability, performance, and ease of integration in Indias leading industries.

Sample Policy, Payment Terms & Certifications

Our BOSCH SERVO DRIVE is available under a premium sample policycontact us for list price quotes and sample dispatch schedules. Convenient payment terms including NEFT, RTGS, and credit are accepted for seamless transactions. Each unit is dispatched with complete documentation and complies with international certifications, ensuring robust quality and operational assurance for your installations.

FAQs of BOSCH SERVO DRIVE:

Q: How is the BOSCH SERVO DRIVE typically utilised in industrial applications?

A: The BOSCH SERVO DRIVE is primarily used to manage motion control in automated machinery, robotics, CNC machines, and packaging equipment, providing precise control of synchronous, asynchronous, and servo motors.Q: What communication interfaces does this drive support for integration?

A: It supports EtherCAT, CANopen, Profibus, and Modbus communication interfaces, enabling seamless integration with various automation systems and industrial networks.Q: When should I consider upgrading the firmware of the BOSCH SERVO DRIVE?

A: Firmware upgrades can be performed via USB or network to ensure optimal performance, access new features, and maintain security. It is recommended to upgrade firmware periodically as updates are released by BOSCH.Q: Where can I mount the BOSCH SERVO DRIVE in my application setup?

A: The drive is designed for panel mounting, allowing easy installation within control cabinets and machinery panels, suitable for industrial environments with IP20 protection.Q: What benefits does the integrated braking unit and Safe Torque Off (STO) feature provide?

A: The integrated braking unit ensures efficient, controlled stopping of motors, while Safe Torque Off (STO) increases safety by securely disconnecting motor power during maintenance or emergencies.Q: How does the BOSCH SERVO DRIVE maintain high efficiency and reliability in operation?

A: With a peak efficiency of up to 98%, robust aluminium housing, and advanced diagnostics, the drive offers excellent energy savings and operational dependability even under challenging industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BOSCH Used SERVO DRIVE Category

BOSCH SERVO DRIVE

Application : Automated Machinery, Robotics, CNC Machines

Features : Compact Design, High Precision, Quick Response

Product Type : Bosch Servo Drive

Material : Metal Housing

Cooling Method : Forced Air Cooling

Storage Temperature : 25C to 70C

BOSCH SERVO DRIVE

Application : Industrial automation, CNC machinery, Robotics

Features : Closed loop control, Auto tuning, Diagnostics display

Product Type : Servo Drive

Material : Industrial grade ABS plastic and metal

Cooling Method : Forced air cooling

Storage Temperature : 25C to +70C

BOCSH CIRCUIT 1 036998_103401

Application : Industrial Automation

Features : Placeholder Features

Product Type : BOCSH CIRCUIT 1 036998_103401

Material : Placeholder Material

Cooling Method : Placeholder Cooling Method

Storage Temperature : Placeholder Storage Temperature

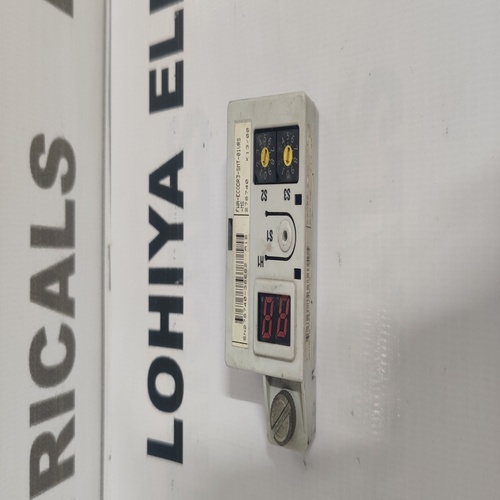

BOSCH INDRAMAT FWA-EC00R3-SMT-01VRS-MS AC SERVO AMPLIFIER DRIVE CONTROLLER

Application : Industrial Automation, Robotics, CNC Machines

Features : Integrated diagnostics, Digital communication, Modular design, Fault memory

Product Type : AC Servo Amplifier Drive Controller

Material : Industrial Grade Metal Casing

Cooling Method : Forced Air Cooling (fanassisted)

Storage Temperature : 25C to +70C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry