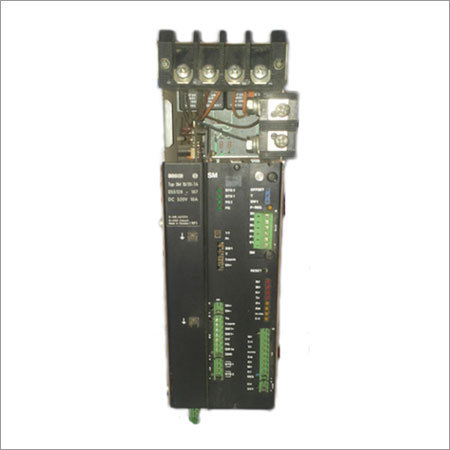

BOSCH SERVO DRIVE

BOSCH SERVO DRIVE Specification

- Current Range

- 0-6 A

- Power Factor

- >0.95

- Connector Type

- Screw Terminal

- Rated Power

- 1.5 kW

- Power Supply

- AC Mains

- Noise Level

- <60 dB

- Output Current

- 4.2 A

- Rated Current

- 4.2 A

- Operating Temperature

- 0C to 55C

- Application

- Automated Machinery, Robotics, CNC Machines

- Phase

- Three Phase

- Cooling Method

- Forced Air Cooling

- Features

- Compact Design, High Precision, Quick Response

- Working Temperature

- 0C to 55C

- Output Type

- Digital/Analog

- Product Type

- Bosch Servo Drive

- Output Power

- 1.5 kW

- Output Frequency

- 0-500 Hz

- Input Voltage

- 380-480 V AC

- Voltage Protection

- Over-voltage, Under-voltage Protection

- Efficiency

- Up to 95%

- Material

- Metal Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to 70C

- Weight

- Approx. 5 kg

- Control Mode

- Position, Speed, Torque Control

- Motor Compatibility

- Synchronous and Asynchronous Servo Motors

- Display

- LED Status Indicators

- Mounting Type

- Panel Mount

- Communication Interface

- RS232, CANopen, EtherCAT

- Protection Class

- IP20

- Backup Memory

- Non-volatile EEPROM

- Braking Unit

- Integrated Dynamic Braking

About BOSCH SERVO DRIVE

Grab the next level of automation with the decorated BOSCH SERVO DRIVE, engineered for incomparable performance in automated machinery, robotics, and CNC machines. With instant checkout, benefit from its advanced RS232, CANopen, and EtherCAT communication interfaces. Access high precision control (Position, Speed, Torque) and enjoy first-string reliability with up to 95% efficiency, metal housing, integrated dynamic braking, and non-volatile EEPROM memory. The panel-mounted, IP20-protected drive supports both synchronous and asynchronous servo motors and boasts quick response, over-/under-voltage safeguards, and LED status indicatorsideal for demanding Indian industry environments.

Highlighted Features and Benefits of BOSCH SERVO DRIVE

The BOSCH SERVO DRIVE stands out with advanced communication options, precise digital/analog output, and a robust metal housing. Its integrated dynamic braking and efficient forced air cooling deliver sustained high performance with minimal noise (<60 dB). Widely used by leading manufacturers and automation specialists, its quick response and compact design provide clear advantages, making it the first-string choice for critical industrial applications that demand accuracy and durability.

Sample Policy, FOB Port & Payment Terms

Upon confirmation of the proposal amount, BOSCH SERVO DRIVE samples are availed for evaluation. Handover of goods follows successful payment, with goods transport arranged via specified FOB ports in India. Payment terms are flexible: options include advance payment or agreed staggered schedules. Our efficient process ensures a smooth transition from order to delivery, fostering reliability and confidence throughout every transaction.

Highlighted Features and Benefits of BOSCH SERVO DRIVE

The BOSCH SERVO DRIVE stands out with advanced communication options, precise digital/analog output, and a robust metal housing. Its integrated dynamic braking and efficient forced air cooling deliver sustained high performance with minimal noise (<60 dB). Widely used by leading manufacturers and automation specialists, its quick response and compact design provide clear advantages, making it the first-string choice for critical industrial applications that demand accuracy and durability.

Sample Policy, FOB Port & Payment Terms

Upon confirmation of the proposal amount, BOSCH SERVO DRIVE samples are availed for evaluation. Handover of goods follows successful payment, with goods transport arranged via specified FOB ports in India. Payment terms are flexible: options include advance payment or agreed staggered schedules. Our efficient process ensures a smooth transition from order to delivery, fostering reliability and confidence throughout every transaction.

FAQs of BOSCH SERVO DRIVE:

Q: How does the BOSCH SERVO DRIVE enhance precision in automated machinery?

A: The BOSCH SERVO DRIVE delivers high-precision control using position, speed, and torque modes, ensuring accuracy through advanced digital/analog output and quick response rates. This makes it ideal for complex automated applications.Q: What communication interfaces are available with this drive?

A: It offers versatile integration through RS232, CANopen, and EtherCAT communication interfaces, making connection with a range of industrial controllers and networks seamless and efficient.Q: When is the ideal time to use the integrated dynamic braking unit?

A: The integrated dynamic braking unit is most beneficial during rapid stopping requirements or emergency deceleration, helping to enhance safety and prolong machine component life.Q: Where can the BOSCH SERVO DRIVE be mounted, and what protection does it offer?

A: The drive is designed for panel mounting and has an IP20 protection class, suitable for controlled industrial environments where it is shielded from solid objects larger than 12.5mm.Q: What is the process to purchase and receive the BOSCH SERVO DRIVE in India?

A: Place your order with the proposal amount; after payment completion, handover is managed through FOB ports with organized goods transport, ensuring timely and secure delivery.Q: What are the main advantages of using this servo drive for robotics or CNC machines?

A: Main advantages include its high efficiency, broad voltage protection, compact design, compatibility with diverse motors, and impressive performance consistency, making it ideal for robotics and CNC machine applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in BOSCH Used SERVO DRIVE Category

BOSCH SERVO DRIVE

Rated Power : 2 kW

Power Supply : AC Mains

Weight : Approx. 1.5 kg

Output Current : Up to 9A

Noise Level : <50 dB

Voltage Protection : Overvoltage and Undervoltage Protection

BOSCH SERVO DRIVE

Rated Power : 1 kW

Power Supply : AC 380480 V

Weight : 2.3 kg

Output Current : Up to 2.5 A

Noise Level : <60 dB

Voltage Protection : Over/Under Voltage Protection

BOSCH SERVO DRIVE

Rated Power : 5 kW

Power Supply : AC 220480 V

Weight : 3.5 kg

Output Current : 5 A

Noise Level : <55 dB

Voltage Protection : Overvoltage, Undervoltage, Short Circuit Protection

BOSCH SM 10,20-TA (2)

Rated Power : Varies

Power Supply : AC

Weight : 2kg

Output Current : 1020A

Noise Level : Low

Voltage Protection : Overvoltage protection included

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry