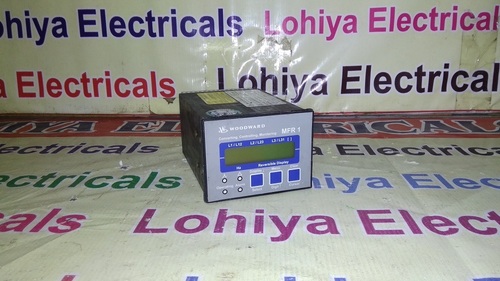

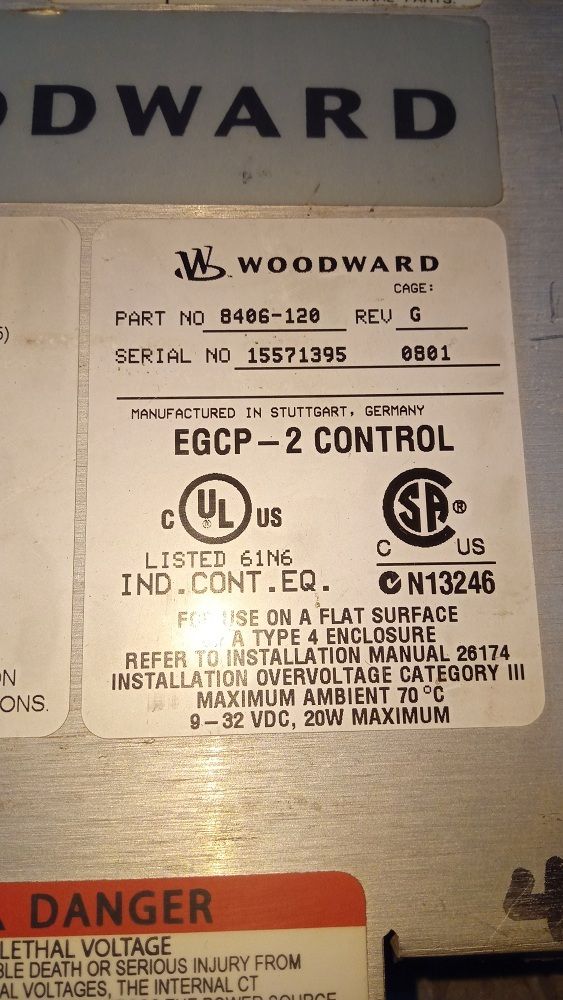

WOODWARD HMI 8406-120 G

WOODWARD HMI 8406-120 G Specification

- Cooling System

- Passive, Fanless

- Cover Material

- Polycarbonate

- Current Rating

- 2A

- Components

- Touch Screen, Processor, Communication Ports

- Rated Insulation Voltage

- 500 V

- Rated Current

- 2A

- Connectivity Type

- Ethernet, Serial (RS232/RS485)

- Base Material

- Metal

- Features

- Touch Operation, Real-Time Data Visualization, Password Protection

- Protection Level

- IP65

- Protection Class

- Class II

- Operating Voltage

- 24 VDC

- Rated Operation Voltage

- 24 VDC

- Panel Type

- Operator Interface Panel

- Cabinet Material

- Metal

- Thickness

- 47 mm

- Way

- Panel Mount

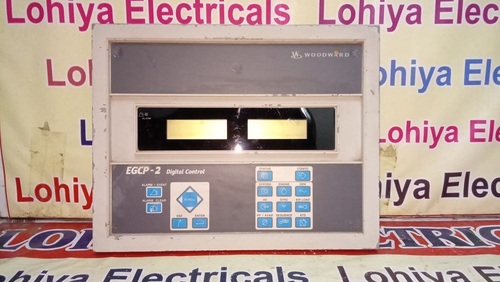

- Control System

- Digital Control

- Product Type

- Human Machine Interface (HMI)

- Material

- Industrial Grade Plastic & Metal

- Surface Finish

- Matte

- Standard

- IEC Standard

- Surface Color

- Grey

- Rated Voltage

- 24 VDC

- Frequency (MHz)

- 50/60 Hz

- Maximum Output Current

- 2A

- Dimension (L*W*H)

- 160 mm x 120 mm x 47 mm

- Application

- Control, Monitoring, Automation

- IP Rating

- IP65

- Display Type

- TFT LCD

- Touch Type

- Resistive Touch

- Humidity Tolerance

- 10% - 90% non-condensing

- Communication Interface

- Ethernet, RS232, RS485, USB

- Programming Software

- Woodward Tool Kit

- Response Time

- <5 ms

- Display Resolution

- 800 x 480 pixels

- Mounting Options

- Panel Mount

- User Interface Languages

- Multi-language support

- Data Storage

- Built-in Flash Memory

- Weight

- Approx 600 g

- Display Size

- 7 inch

- Power Consumption

- Max 12W

- Backup Functionality

- Battery-backed RTC

- Graphic Capability

- PNG, JPG image support

- Operating Temperature Range

- -10°C to +60°C

- Product Code

- 8406-120 G

About WOODWARD HMI 8406-120 G

Specific and General Use Applications

WOODWARD HMI 8406-120 G excels as a control, monitoring, and automation solution in diverse industrial environments. Used as an operator interface panel, it facilitates digital control systems and real-time data supervision, making it fit for general industrial processes and specific automation tasks. This ace panel is suitable for factories, utilities, and automation laboratories, where reliability and advanced monitoring are essential for seamless operation and safety.

Goods Transport, FOB Port & Supply Policy

Goods shipped are dispatched through reliable transport partners, with primary FOB port arrangements to streamline international deliveries. Valuation is based on competitive pricing structures, ensuring accessibility for global buyers. Sample policy includes the provision of product samples on request, subject to terms. With a strong supply ability, orders for the WOODWARD HMI 8406-120 G panel are fulfilled efficiently, guaranteeing timely dispatch and delivery to customers worldwide.

FAQs of WOODWARD HMI 8406-120 G:

Q: How can the WOODWARD HMI 8406-120 G be installed in an industrial setting?

A: It is designed for panel mounting, allowing easy integration into standard industrial control cabinets. The installation process is straightforward, thanks to its compact dimensions and clear instructions provided in the programming software toolkit.Q: What applications benefit most from this operator interface panel?

A: The panel is ideal for control, monitoring, and automation in manufacturing plants, utility systems, and automated facilities, where reliability, real-time data visualization, and multi-language user interface are necessary.Q: When is it necessary to utilize the backup functionality of the HMI?

A: The battery-backed RTC and backup options are critical during power disruptions or maintenance to preserve system time and data settings for uninterrupted operations.Q: Where can users access technical support for programming and setup?

A: Technical support is accessible through Woodwards official channels or authorized suppliers, offering guidance for programming, maintenance, and troubleshooting.Q: What is the process for requesting a sample of WOODWARD HMI 8406-120 G?

A: Buyers may request product samples via the supplier, usually subject to sample policy terms, with quick valuation and shipment through designated FOB ports for international buyers.Q: How does the resistive touch screen enhance operation efficiency?

A: Resistive touch technology allows precise input, even with gloves, making it suitable for harsh industrial environments and improving operator accuracy and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in WOODWARD CPU HMI MITTER Category

WOODWARD HMI 5448-899 B

Protection Level : IP65

Operating Voltage : 24 VDC

IP Rating : Other, IP65

Standard : IEC 61131, CE Certified

Protection Class : Class II

Cabinet Material : Polycarbonate

WOODWARD HMI

Protection Level : IP65

Operating Voltage : 24V DC

IP Rating : Other, IP65

Standard : IEC 61131

Protection Class : Class I

Cabinet Material : Polycarbonate

WOODWARD HMI 5448-914 D

Protection Level : Other, IP65 (Front Panel)

Operating Voltage : 24 V DC

IP Rating : Other, IP65

Standard : IEC/EN Standard Compliant

Protection Class : Class II

Cabinet Material : Rugged ABS Plastic

WOODWARD HMI 8406-120 F

Protection Level : Other, IP66 (front), IP20 (rear)

Operating Voltage : 24 V DC

IP Rating : Other, IP66 (front), IP20 (rear)

Standard : IEC 611312, CE, UL

Protection Class : Class I

Cabinet Material : Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry