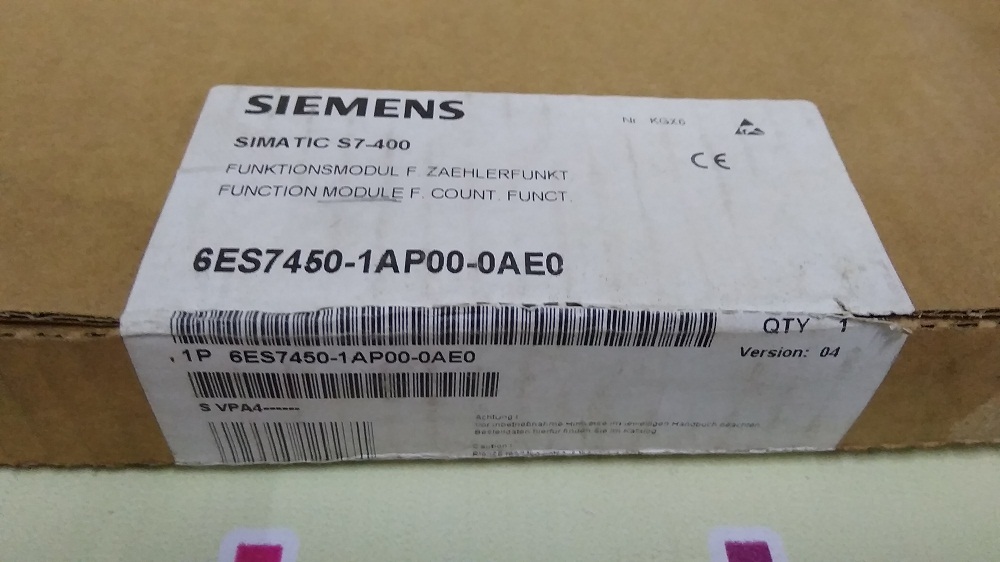

SIEMENS S7 400 MODULE

SIEMENS S7 400 MODULE Specification

- Rated Current

- N/A (module-dependent)

- Rated Power

- N/A (for modules, see specific power supply)

- Power Factor

- >0.90 (power supply only)

- Operating Temperature

- 0C to +60C

- Cooling Method

- Passive (natural air) Cooling

- Current Range

- N/A (module-dependent)

- Features

- Modular Design, Hot Swapping, High Reliability, Flexible Configuration, Communication Interfaces

- Working Temperature

- 0C to +60C

- Noise Level

- <55 dB (max, passive cooling)

- Power Supply

- 24 V DC, 120/230 V AC (model dependent)

- Application

- Industrial Automation, Process Control, Machine Automation

- Connector Type

- Screw Terminal and/or Plug-in Connectors

- Output Type

- Digital / Analog (model dependent)

- Phase

- Single/Three Phase (depends on module application)

- Output Current

- N/A (module-dependent)

- Product Type

- Programmable Logic Controller (PLC) Module

- Output Power

- N/A (module-dependent)

- Output Frequency

- N/A (module-dependent)

- Input Voltage

- 24 V DC / 120-230 V AC (model specific)

- Voltage Protection

- Overvoltage Protection: Yes

- Efficiency

- Up to 90% (module dependent)

- Material

- Industrial Grade Plastic and Metal Housing

- Line Regulation

- <0.1% (for input module)

- Storage Temperature

- -40C to +70C

- Weight

- Approx. 500-1500 g (module type)

About SIEMENS S7 400 MODULE

Versatile Industrial Application

The SIEMENS S7 400 MODULE is engineered for seamless integration into industrial automation, process control, and machine automation environments. Application methods include modular configuration and direct mounting on DIN Rail or racks for streamlined setup. Commercial users benefit from flexible expansion capability, rapid response times, and intuitive status LEDs, enhancing visibility and control. Utilise its advanced communication interfaces to power sophisticated automation in manufacturing plants, assembly lines, and production facilities, delivering reliable and scalable performance daily.

Packaging & Delivery Insights

Handover of the SIEMENS S7 400 MODULE comes with robust packaging designed to minimise expenditure on transit damage and maximise safety. Each unit is securely packed to withstand storage temperatures from -40C to +70C. Sample policy estimates can be provided upon request, allowing clients to test suitability before large-scale deployment. Main domestic markets include industrial automation businesses and process control firms, with swift delivery and responsive support ensuring prompt installation and operational readiness.

FAQs of SIEMENS S7 400 MODULE:

Q: How do I mount the SIEMENS S7 400 MODULE in industrial setups?

A: The SIEMENS S7 400 MODULE can be installed using DIN Rail or rack mounting, depending on your application requirements and space constraints.Q: What communication protocols does the module support for industrial automation?

A: This module supports PROFIBUS, PROFINET, MPI, and Ethernet, allowing versatile connectivity with a variety of network infrastructures.Q: When can I expand or hot swap modules in the S7 400 system?

A: Expansion or hot swapping is supported during maintenance or system upgrades, enabling you to add modules without significant downtime.Q: Where is the SIEMENS S7 400 MODULE best utilised in commercial applications?

A: It is mainly used in industrial automation, process control, and machine automation facilities where high reliability and flexible operation are essential.Q: What software is needed for programming the S7 400 MODULE?

A: You should use SIMATIC STEP 7 or TIA Portal programming software to configure and manage CPU, I/O, and communication processes.Q: How does the SIEMENS S7 400 enhance reliability in automation systems?

A: Features like battery-backed RAM for data retention, IP20 protection, modular design, and passive cooling ensure gilt-edged reliability in critical environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEMENS SIMATIC S7 400 MODULE/ CP Category

SIEMENS S7-400 MODULE 6ES7 441-2AA03-0AE0

Material : Industrialgrade plastic and metal

Working Temperature : 0C to +60C

Features : 16 digital output channels, diagnostic LED display, plugin connector

Operating Temperature : 0C to +60C

Weight : Approx. 450 g

Application : Industrial Automation, Process Control

Latest Modular SIEMENS SIMATIC S7 400 MODULE 6ES7 431-7QH00-0AB0

Material : Industrial Grade Plastic and Metal

Working Temperature : 0C to +60C

Features : HART communication supported, Hot Swapping, Diagnostics LEDs, Channel Diagnostics

Operating Temperature : 0C to +60C

Weight : Approx. 450 g

Application : Industrial Automation, PLC Control Systems

SIEMENS SIMATIC S7 400 6ES7 416-2XN05-0AB0 MODULE

Material : Industrialgrade plastic and metal housing

Working Temperature : 0C to +60C

Features : Redundant power supply capability, extended memory, high speed processing, diagnostic LEDs

Operating Temperature : 0C to +60C

Weight : Approx. 800 g

Application : Industrial automation, process control

SIEMENS SIMATIC S7 400 MODULE 6ES7 441-2AA02-0AE0

Material : Industrial grade plastic and metal

Working Temperature : 0C to +60C

Features : Hotswapping, diagnostic functions, shortcircuit proof outputs

Operating Temperature : 0C to +60C

Weight : Approx. 500 g

Application : Industrial automation, process control, PLC expansion

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry