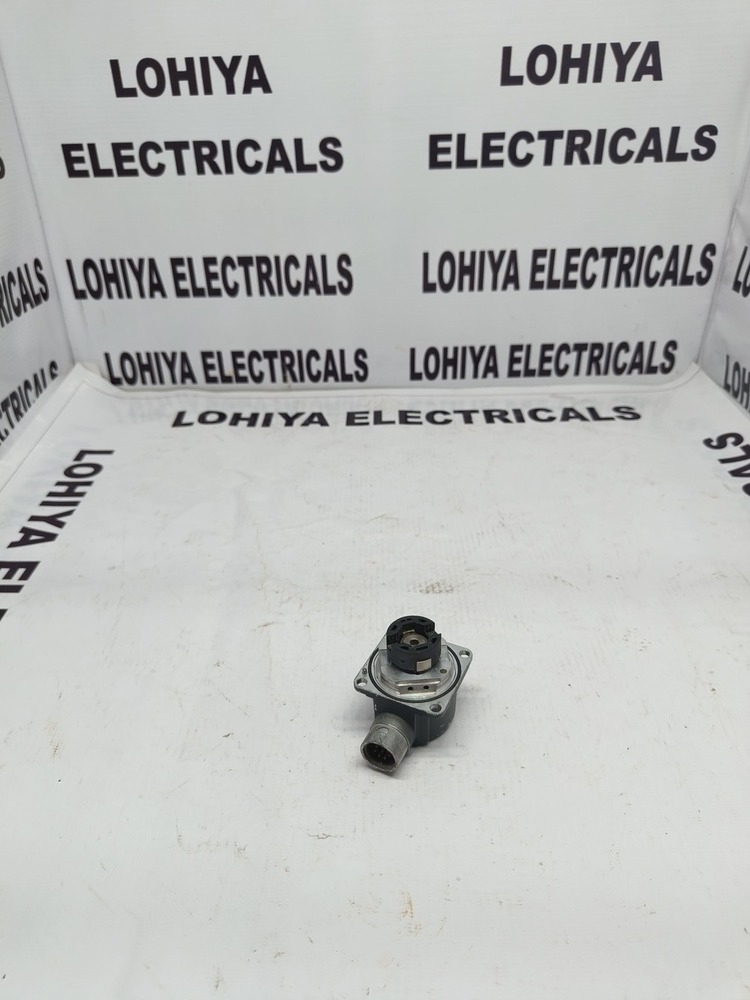

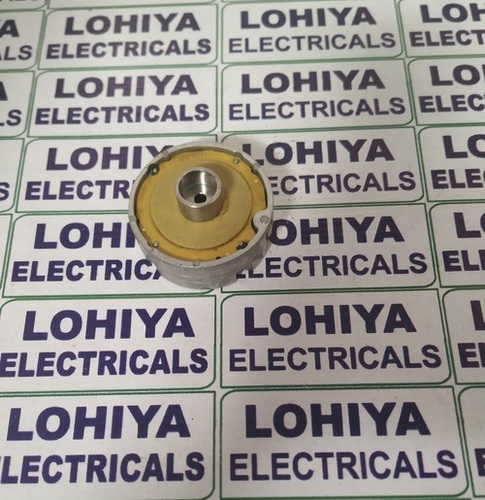

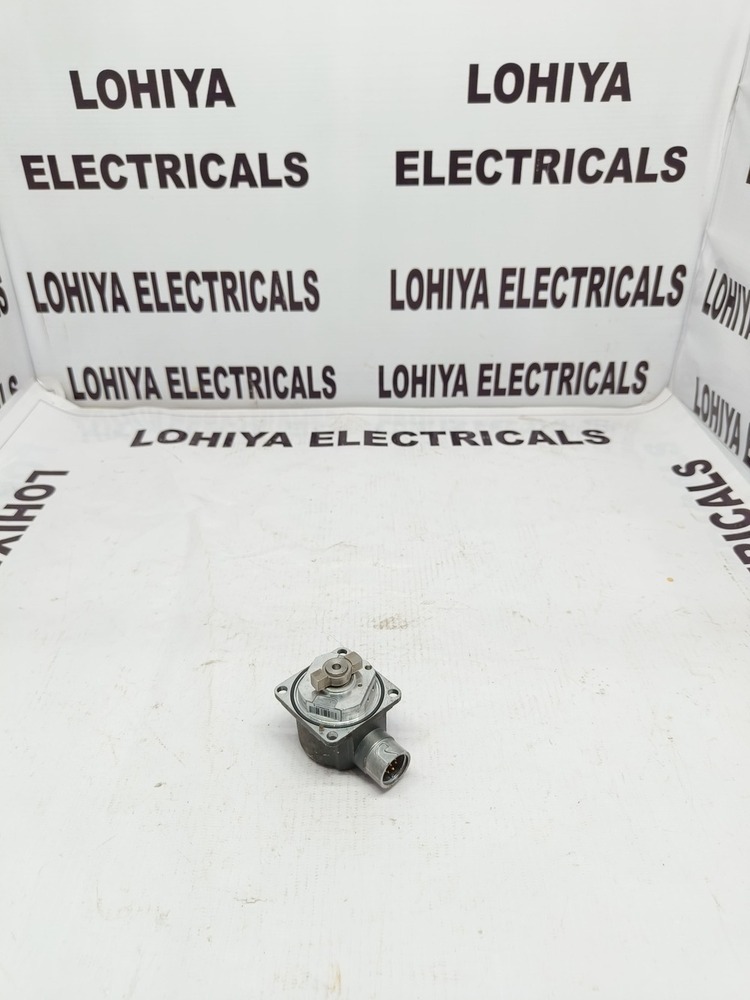

SIEMENS C6FX2001-3EB02 INCREMENTAL ENCODER

SIEMENS C6FX2001-3EB02 INCREMENTAL ENCODER Specification

- Protection Class

- Class I

- Cooling System

- Passive

- Panel Type

- Closed Type

- Rated Operation Voltage

- 5V DC

- Rated Insulation Voltage

- 500V

- Features

- Precision Positioning, Durable Construction, High Output Frequency

- Way

- Single

- Base Material

- Aluminum Alloy

- Operating Voltage

- 5V DC

- Connectivity Type

- Wire

- Control System

- Electronic

- Thickness

- 45 mm

- Current Rating

- 50 mA

- Cover Material

- Plastic

- Components

- Encoder Shaft, Signal Output Cable

- Rated Current

- 50 mA

- Protection Level

- IP65

- Product Type

- INCREMENTAL ENCODER

- Material

- Metal

- Surface Finish

- Anodized

- Standard

- IEC

- Surface Color

- Silver Gray

- Rated Voltage

- 5V DC

- Frequency (MHz)

- 5 MHz

- Maximum Output Current

- 50 mA

- Dimension (L*W*H)

- 70 x 45 x 45 mm

- Application

- Industrial Automation, Position Feedback

- IP Rating

- IP65

- Model Number

- C6FX2001-3EB02

- Output Type

- Incremental

- Shaft Type

- Solid Shaft

- Shaft Diameter

- 6 mm

- Mounting Method

- Flange Mount

- Vibration Resistance

- 10 g (10...2000 Hz)

- Output Signal

- A, B, Z channels

- Storage Temperature Range

- -40C to +100C

- Load Capacity

- 10 N axial / 30 N radial

- Cable Length

- 2 meters

- Shock Resistance

- 50 g (11 ms)

- Operating Temperature Range

- -25C to +85C

- Encoder Resolution

- 1000 pulses/revolution

- Response Time

- <1 s

About SIEMENS C6FX2001-3EB02 INCREMENTAL ENCODER

Optimal Usage and Application Directions

The SIEMENS C6FX2001-3EB02 Incremental Encoder is primarily used for position feedback and precision control in industrial automation. To use, simply mount the encoder with the flange mount fixing, connect its 2-meter cable to your control system, and ensure the environmental conditions align with the rated operating range. It is designed for machines requiring high-resolution feedback, making it ideal for automated conveyors, packaging systems, and robotics.

Global Export Excellence and Swift Delivery

Our immaculate SIEMENS C6FX2001-3EB02 Incremental Encoder is available for express shipping to renowned markets worldwide, including Europe, Southeast Asia, Africa, and the Middle East. With a substantial supply ability, your order is processed efficiently, allowing for timely arrival and minimal outlay. Each unit is packaged securely with protective foam and anti-static material, ensuring the opulent encoder reaches you in pristine condition.

FAQs of SIEMENS C6FX2001-3EB02 INCREMENTAL ENCODER:

Q: How should the SIEMENS C6FX2001-3EB02 Incremental Encoder be installed?

A: Mount the encoder using its flange mounting method and connect the signal output cable to the control system, ensuring all wiring is secure before powering up.Q: What are the main benefits of using this encoder in industrial automation?

A: This model offers precision positioning, durability under high loads and vibrations, and quick response times, making it a cost-effective solution for elite industrial applications.Q: When is it ideal to use this incremental encoder?

A: It is ideal for applications requiring high-resolution position feedback, such as automated assembly lines or robotics, especially where durability and accuracy are paramount.Q: Where can this encoder be supplied or shipped to?

A: This encoder can be sourced and shipped globally, with express shipping available to prominent markets in Europe, Southeast Asia, Africa, and the Middle East.Q: What process should be followed to ensure optimal operation of this encoder?

A: Check compatibility with control systems, confirm correct mounting and wiring, maintain environmental conditions within the specified range, and periodically inspect the encoder for consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEMENS ENCODER Category

SIEMENS HGX-0572896.a 835376803/KN ENCODER

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High precision, Robust design, Maintenancefree, Vibration resistant

Rated Operation Voltage : 24 VDC

Rated Insulation Voltage : 500 V AC

Material : Other, Aluminum Alloy, Industrialgrade polymers

SIEMENS (1P) 6FX2001-5FD13-0AA1 ABSOLUTE ENCODER

Minimum Order Quantity : 1 Piece

Features : Absolute Position Sensing, Compact Design, Robust Construction

Rated Operation Voltage : 5V DC

Rated Insulation Voltage : 500V AC

Material : Metal

SIEMENS ENCODER EQI 1325.020-32

Features : High precision, robust housing, optical scanning, multiturn absolute position

Rated Operation Voltage : 5V DC

Rated Insulation Voltage : 60 V DC

Material : Other, Metal Housing with Precision Sealed Components

SIEMENS HGX-0572891.0 230206067/R2 ENCODER

Minimum Order Quantity : 1 Piece

Features : High accuracy, robust housing, shock resistant

Rated Operation Voltage : 1030 VDC

Rated Insulation Voltage : 500V

Material : Other, Metal body, electronic components

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry