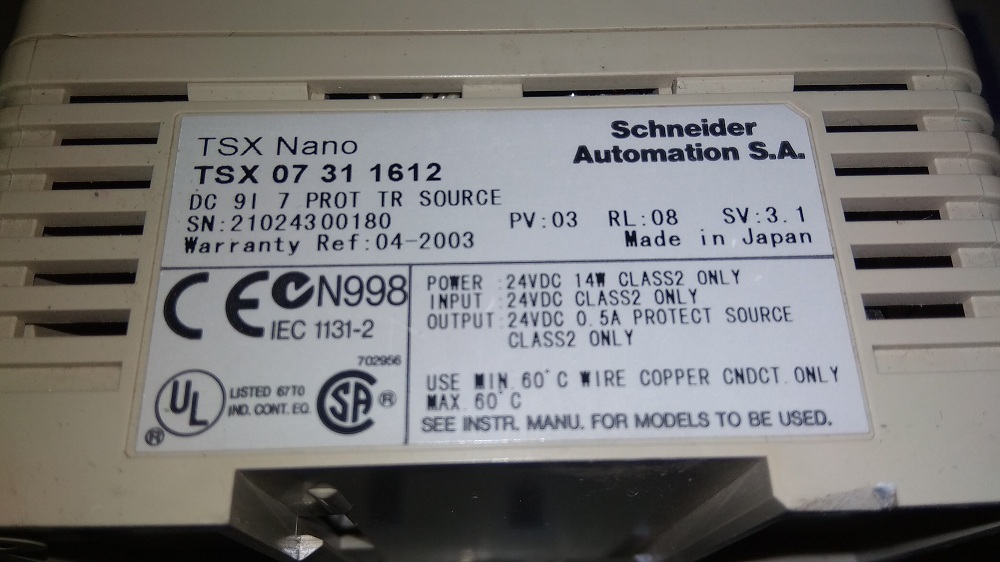

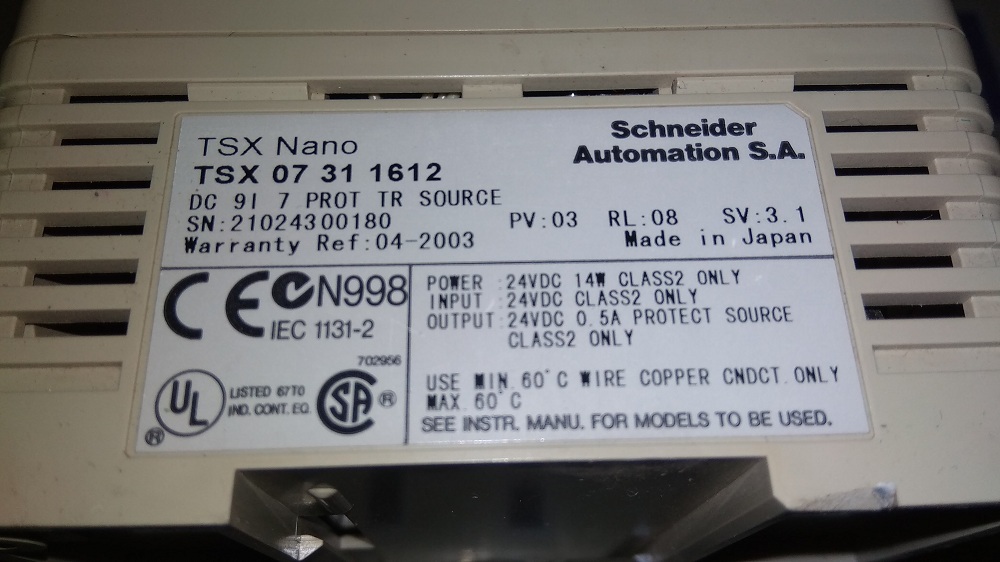

SCHNEIDER PLC

SCHNEIDER PLC Specification

- Connector Type

- Screw Terminal / Plug-in Terminal Blocks

- Power Factor

- >0.95

- Application

- Industrial Automation, Process Control

- Operating Temperature

- 0C to +60C

- Noise Level

- < 60 dB(A)

- Features

- Integrated Communication Ports, Expandable I/O, LCD Display (select models), DIN Rail Mounting, Easy Programming

- Output Type

- Relay, Transistor (depending on variant)

- Phase

- Single Phase / Three Phase (options available)

- Working Temperature

- 0C to +60C

- Cooling Method

- Natural Air Cooling

- Rated Current

- Model Specific

- Output Current

- Configurable - model dependent

- Current Range

- Up to 10A (model dependent)

- Power Supply

- 24V DC / 220V AC (universal input)

- Rated Power

- Model Specific

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- Relay/Transistor Output (as per model)

- Output Frequency

- 50/60 Hz

- Input Voltage

- 24V DC / 220V AC

- Voltage Protection

- Overvoltage and Surge Protection

- Efficiency

- High Efficiency Operation

- Material

- High Strength Plastic Housing

- Line Regulation

- < 0.5%

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 500g

- Software Compatibility

- EcoStruxure Machine Expert, SoMachine

- Indicator LEDs

- Status, Power, Communication, Fault indication

- Display

- Integrated LCD/Text display (on select models)

- Safety Functions

- Short Circuit and Overload Protection

- Communication Interface

- Modbus, RS232/RS485, Ethernet (options available)

- Protection Class

- IP20/IP40 (model dependent)

- Expansion Capability

- Supported Digital & Analog I/O modules

- Scan Time

- 0.1 ms per instruction (typical)

- Mounting Type

- DIN Rail Mounting

- Data Retention

- EEPROM/Flash, up to 10 years

- Program Memory

- Up to 256 KB (model dependent)

About SCHNEIDER PLC

Application Areas and Usage Types of SCHNEIDER PLC

The SCHNEIDER PLC excels in diverse industries, making it ideal for industrial automation and process control applications. Its robust expansion capability supports usages from factory line automation to advanced building management systems. Operators benefit from easy integration into data acquisition networks and seamless handling of mixed digital and analog inputs in demanding environments. Engineered for both continuous and batch-processing operations, this PLC adapts to environments requiring flexible, scalable, and high-stability solutions.

Sample Policy, Export Markets, and Supply Rate for SCHNEIDER PLC

We ensure our SCHNEIDER PLCs are offered at the lowest price available in the market, balancing exceptional value with supreme quality. Samples are provided under a clear policy for evaluation before bulk commitment. Our main export markets are spread across Asia, Middle East, and Africa, with consistent supply ability to meet dynamic demands. Rapid transportation and competitive rates guarantee on-time delivery, while our streamlined logistics minimize disruptions for our valued global clientele.

FAQs of SCHNEIDER PLC:

Q: How is the SCHNEIDER PLC typically mounted in an industrial setting?

A: The SCHNEIDER PLC is designed for convenient DIN Rail Mounting, allowing swift and secure installation within industrial control enclosures.Q: What communication interfaces are available with SCHNEIDER PLC models?

A: Depending on the model, SCHNEIDER PLCs offer Modbus, RS232/RS485, and Ethernet communication interfaces, providing flexible connectivity for automation and monitoring requirements.Q: Where can the SCHNEIDER PLC be effectively deployed?

A: The SCHNEIDER PLC is ideal for industrial automation, process control, building management, and manufacturing applications that demand reliability, scalability, and flexibility.Q: What is the benefit of the expandable I/O capability in SCHNEIDER PLCs?

A: Expandable digital and analog I/O modules enable users to customize the PLC for specific process needs, supporting future upgrades and diverse control applications.Q: How does the SCHNEIDER PLC ensure data and equipment safety?

A: The PLC features EEPROM/Flash data retention for up to 10 years and provides built-in short circuit, overload, and voltage surge protection for immaculate operational safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

SCHNEIDER PLC

Product Type : SCHNEIDER PLC (Programmable Logic Controller)

Connector Type : Screw Terminal

Operating Temperature : 0C to +55C

Application : Industrial Automation, Machine Control

Phase : Single Phase

Working Temperature : 0C to +55C

SCHNEIDER PLC

Product Type : PLC (Programmable Logic Controller)

Connector Type : Removable Screw Terminal

Operating Temperature : 0 to 55C

Application : Industrial Automation, Process Control

Phase : Single Phase

Working Temperature : 0C to 55C

Power Supplies MODICON QUATUM MODULE

Product Type : MODICON QUANTUM Power Supply Module

Connector Type : Screw Terminal Block

Operating Temperature : 0C to +60C

Application : PLC Power Supply for MODICON Quantum Series

Phase : Single Phase

Working Temperature : 0C to +60C

SCHNEIDER HMI XBT0T2110

Product Type : HMI (HumanMachine Interface)

Connector Type : Ethernet/USB

Operating Temperature : 0C to 50C

Application : Industrial Automation

Phase : Single Phase

Working Temperature : 0C to 50C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry