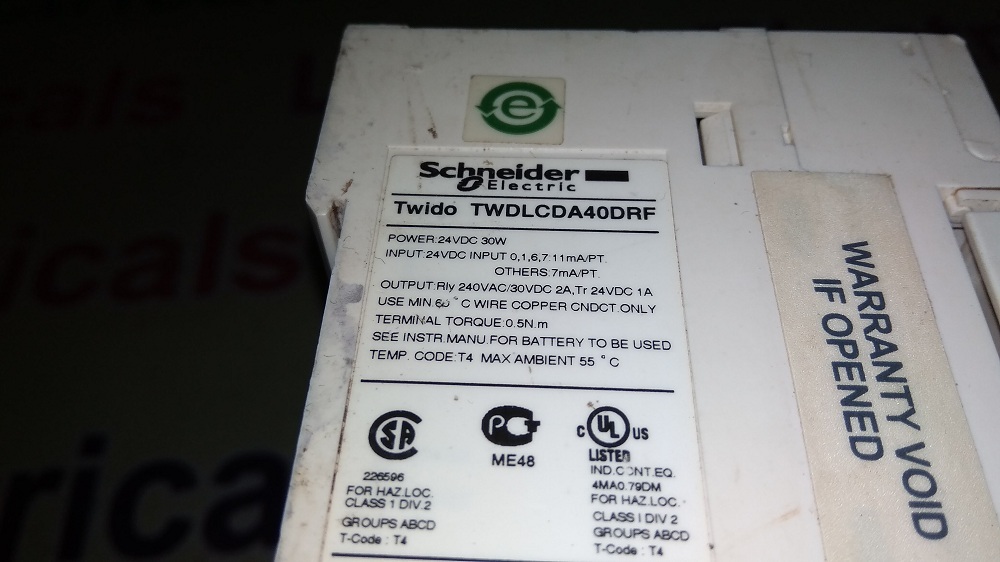

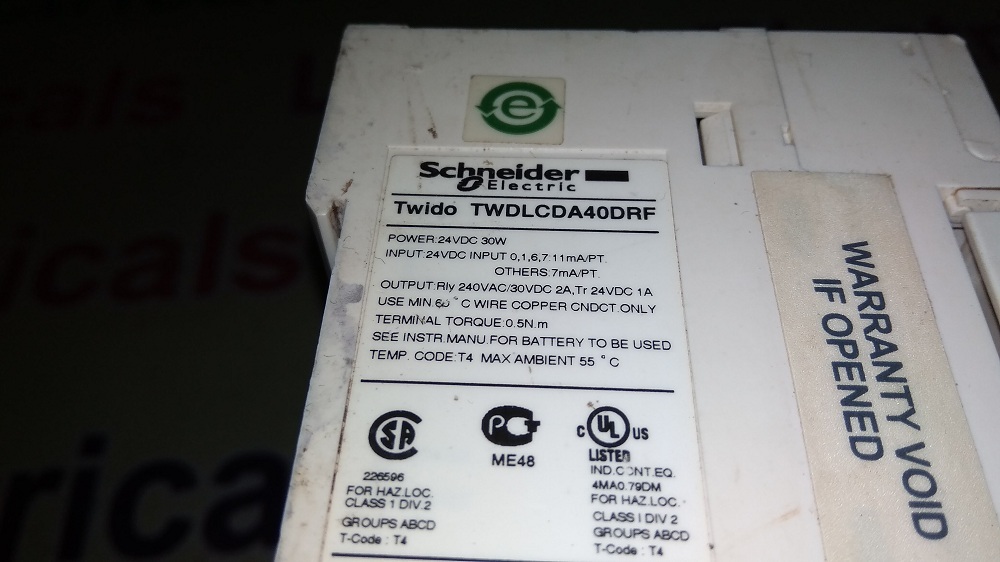

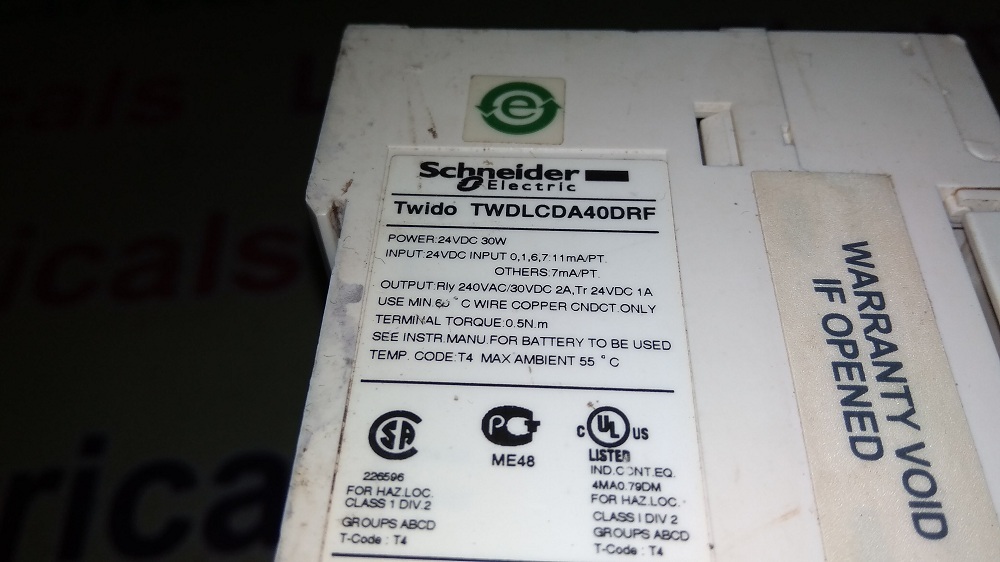

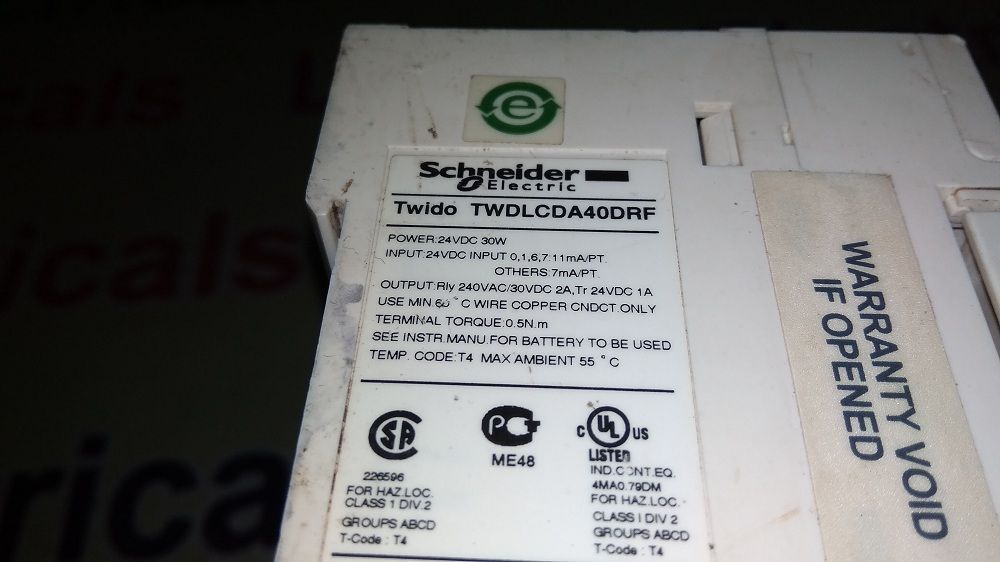

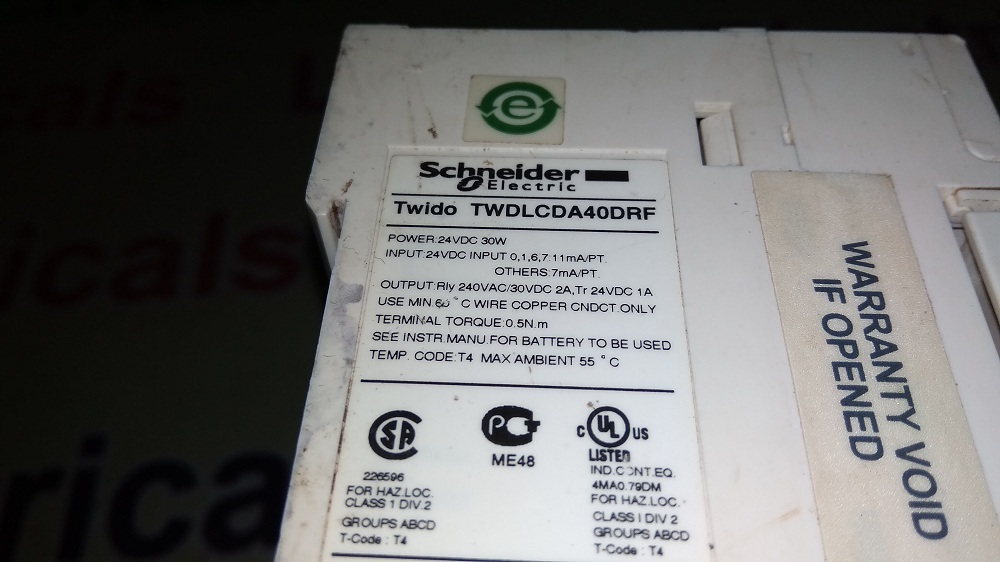

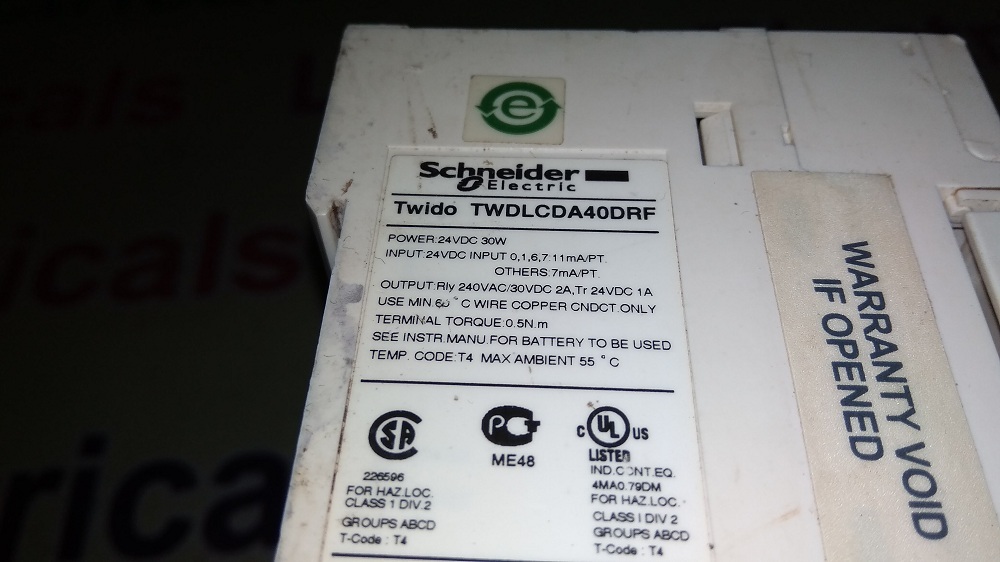

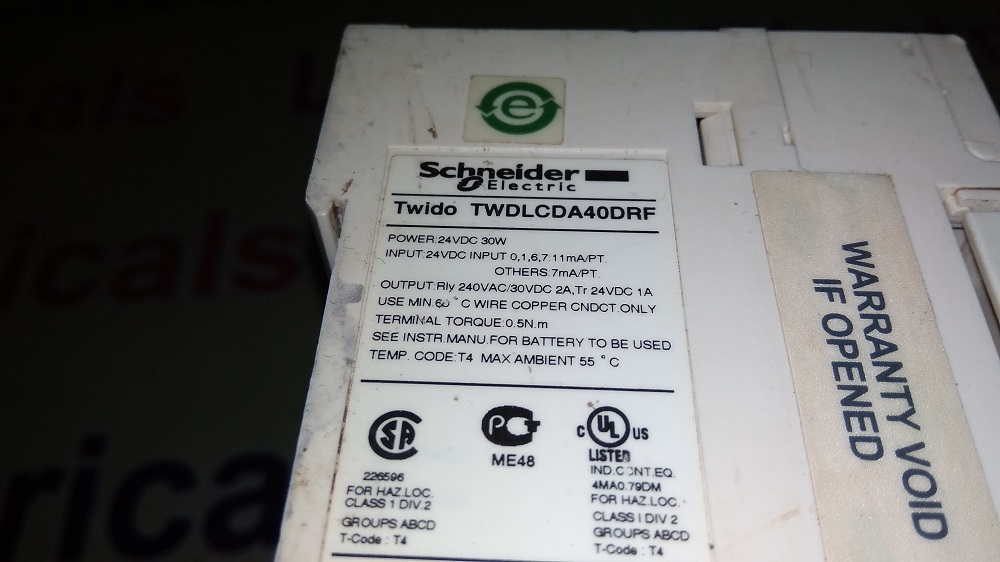

SCHNEIDER PLC

SCHNEIDER PLC Specification

- Rated Current

- 2A

- Power Factor

- >0.95

- Operating Temperature

- 0C to +55C

- Application

- Industrial Automation, Machinery Control, Process Control

- Output Type

- Relay / Transistor (Configurable)

- Features

- Compact Module, Expandable I/O, LED Indicators

- Noise Level

- <45 dB

- Rated Power

- 48W

- Output Current

- 2A

- Current Range

- 0.1A 2A

- Connector Type

- Screw Terminal Blocks

- Working Temperature

- 0C to +55C

- Cooling Method

- Natural Air Cooling

- Power Supply

- AC/DC Universal

- Phase

- Single Phase

- Product Type

- PLC (Programmable Logic Controller)

- Output Power

- 24V DC, 2A

- Output Frequency

- 50/60 Hz

- Input Voltage

- 220V AC

- Voltage Protection

- Overvoltage and undervoltage protection

- Efficiency

- High (typically >90%)

- Material

- ABS Plastic / Metal Enclosure

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- 550g (approx)

- Communication Ports

- RS232 / RS485

- Mounting Type

- DIN Rail Mounting

- Analog Inputs

- 2 Channels (optional)

- Protection Level

- IP20

- Response Time

- <1 ms

- Display Type

- LED Status Display

- Programming Software

- Schneider SoMachine / EcoStruxure Machine Expert

- Digital Inputs

- 8 Channels

- Digital Outputs

- 6 Channels

About SCHNEIDER PLC

Competitive Advantages of SCHNEIDER PLC

SCHNEIDER PLC stands out with its compact design, expandable I/O, and high reliability for industrial automation. Used by discerning process engineers and manufacturers, it ensures rapid response and advanced voltage protection, keeping operations seamless. Its compatibility with EcoStruxure and SoMachine software distinguishes it from competitors, providing a unique programming edge. Trusted for critical machinery control, it offers rarefied performance in demanding environments.

Market Reach, Certifications, and Sample Availability

Primarily serving the Indian domestic market, SCHNEIDER PLCs are delivered efficiently with clear proposal amounts covering expenditure and transportation. These units ship with comprehensive certifications, ensuring assured quality and regulatory compliance. For large projects, sample policies are in place, supporting preliminary assessments before bulk procurement. Both the supplier and trader network offers robust after-sales support for any further requirements.

FAQs of SCHNEIDER PLC:

Q: How is the SCHNEIDER PLC installed in industrial environments?

A: The SCHNEIDER PLC is designed for quick and straightforward DIN rail mounting, making it suitable for a variety of industrial setups.Q: What is the communication process for connecting external devices to the PLC?

A: You can connect external devices using the built-in RS232 or RS485 communication ports, facilitating seamless machine integration and data transfer.Q: When should you consider the optional analog input channels?

A: Opt for the analog inputs when your application requires precise analog signal monitoring, such as sensors in process control or advanced automation tasks.Q: Where is SCHNEIDER PLC predominantly used?

A: SCHNEIDER PLCs are widely used in industrial automation, machinery control, and process management across Indias engineering and manufacturing sectors.Q: What are the major benefits of using SCHNEIDER PLC over alternatives?

A: Key benefits include high efficiency, configurable outputs, advanced voltage protection, rapid response times, and compatibility with Schneiders leading programming software.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

PROCESSOR MODULE

Material : FR4 PCB, Aluminium Housing

Application : Industrial Automation, Control Systems

Features : Low Power Consumption, High Stability, Compact Design

Product Type : Processor Module

Connector Type : Pluggable Terminal Block, Header Pins

Cooling Method : Passive Heat Sink

SCHNEIDER AC SERVO DRIVE

Material : HighGrade Engineering Plastic and Metal

Application : Precision Motion Control, CNC Machines, Robotics, Packaging Machinery

Features : Auto Tuning, Compact Design, HighSpeed Response, Builtin Safety Functions

Product Type : AC Servo Drive

Connector Type : Screw Terminal / Plugin Terminal

Cooling Method : Fan Cooling

SCHNEIDER MODULE TSXDSY16T2

Material : Plastic and metal

Application : Industrial automation, PLC

Features : 16 transistor outputs, diagnostic LED indicators, removable terminal block

Product Type : Discrete Output Module

Connector Type : Removable primavera connector

Cooling Method : Natural convection

SCHNEIDER ELECTRIC MODULE TSXDEZ232D2

Material : PCB and Electronic Components

Application : Industrial Automation

Features : Digital Module

Product Type : Communication Module

Connector Type : Edge Connector

Cooling Method : None

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry