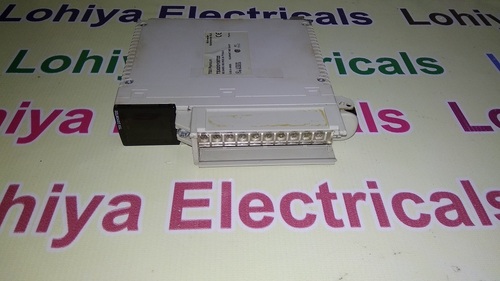

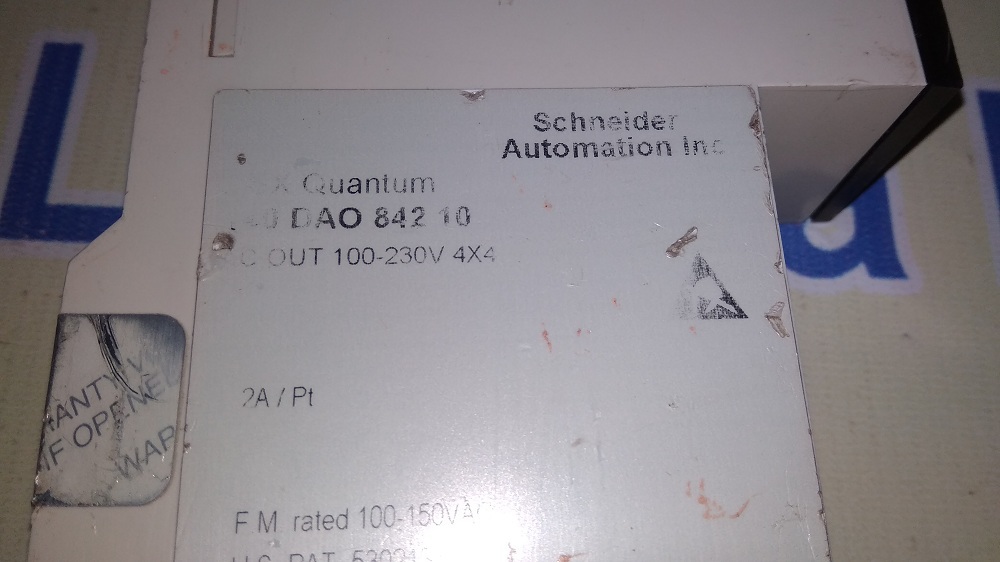

SCHNEIDER PLC

SCHNEIDER PLC Specification

- Power Factor

- >0.95

- Connector Type

- Screw Terminal

- Rated Power

- Serves as logic controller, power per output 24V DC

- Output Type

- Relay, Transistor (sink/source depending on model)

- Phase

- Single Phase

- Output Current

- 0.5A (relay), up to 2A (transistor)

- Cooling Method

- Natural Air Cooling

- Working Temperature

- 0C to 55C

- Noise Level

- <40 dB

- Features

- Modular Expansion, Communication Ports (Ethernet/RS485), LED Indication, Short Circuit Protection

- Operating Temperature

- 0C to 55C

- Application

- Industrial Automation, Machine Control, Process Automation

- Rated Current

- Max. 2A per output

- Current Range

- 0.1A to 2A depending on output module

- Power Supply

- Integrated AC Supply

- Product Type

- PLC (Programmable Logic Controller)

- Output Power

- 24 V DC (digital outputs), relay and transistor options

- Output Frequency

- 50/60 Hz

- Input Voltage

- 100-240 V AC

- Voltage Protection

- Overvoltage and surge protection integrated

- Efficiency

- Up to 90%

- Material

- High-grade Industrial Plastic Housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 0.6 kg

- Display

- None (LED Indicators)

- Communication Ports

- RS232/RS485/Ethernet

- Program Memory

- 8 KB

- PLC Programming Language

- Ladder Logic, FBD, IL

- Mounting Type

- DIN Rail Mounting

- Number of Inputs

- 8 Digital Inputs

- Number of Outputs

- 6 Relay Outputs

- Expansion

- Supported with Expansion Modules

About SCHNEIDER PLC

Versatile Applications for Industrial Demands

The SCHNEIDER PLC excels in a wide range of plant applications, from machine control to comprehensive process automation. Whether for manufacturing facilities or assembly lines, this PLC proves ideal for both specific and general uses. Its adaptability and robust design make it suitable for various operational settings, ensuring consistent performance and reliability in industrial environments.

Reliable Supply, Swift Processing, and Simple Ordering

With substantial supply ability, SCHNEIDER PLC units are shipped promptly, ensuring rapid order processing for every customer. Sample availability allows for product trials before large-scale implementation. Secure payment terms are established to facilitate smooth transactions, while shipped goods arrive safely with careful handling. Timely delivery and dependable logistics underpin each order, from initial inquiry to final installation.

FAQs of SCHNEIDER PLC:

Q: How can SCHNEIDER PLC be customized for specific automation tasks?

A: SCHNEIDER PLC supports multiple programming languages like Ladder Logic, FBD, and IL, allowing engineers to tailor automation sequences for distinct applications. Modular expansion options further enhance customization to meet unique plant requirements.Q: What communication interfaces are available on the SCHNEIDER PLC?

A: This PLC is equipped with RS232, RS485, and Ethernet ports, providing versatile connectivity for integration into various industrial network architectures.Q: Where is the best place to use SCHNEIDER PLC in industrial applications?

A: SCHNEIDER PLC is ideal for machine control, process automation, and general plant automation tasks in industries requiring reliable and scalable automation solutions.Q: What is the process for ordering and receiving SCHNEIDER PLC units?

A: Customers can place orders through authorized suppliers or traders. Orders are swiftly processed, and the goods are shipped using secure logistics channels to ensure timely delivery.Q: What key benefits does the SCHNEIDER PLC offer for industrial users?

A: Key benefits include high efficiency (up to 90%), overvoltage and surge protection, modular expandability, and a classic, imposing reliability recognized in hot-selling industrial segments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

SCHNEIDER PLC

Operating Temperature : 0C to 55C

Weight : Approx 0.5 to 1.5 kg (model dependent)

Storage Temperature : 25C to +70C

Features : Modular design, high reliability, digital and analog input/output, RS232/RS485 communication

Voltage Protection : Overvoltage and shortcircuit protection

Noise Level : Low, <55 dB

SCHNEIDER ELECTRIC PLC CONTROLLER

Operating Temperature : 10C to +60C

Weight : 0.5 kg

Storage Temperature : 40C to +85C

Features : Programmable, Expandable I/O, LED Indicators

Voltage Protection : Overvoltage & Undervoltage Protection

Noise Level : <50 dB

SCHNEIDER MODULE

Operating Temperature : 0C to +60C

Weight : Approx. 200 g

Storage Temperature : 40C to +85C

Features : Short Circuit Protection, Modular Design, LED Status Indication

Voltage Protection : Overvoltage and Undervoltage Protection

Noise Level : <50 dB

SCHNEIDER ELECTRIC HMI

Operating Temperature : 0C to +50C

Weight : Approx. 0.8 2.2 kg (model dependent)

Storage Temperature : 20C to +60C

Features : Resistive or capacitive touchscreen, LED backlight, multilanguage support, Ethernet/Serial/USB connectivity

Voltage Protection : Overvoltage and reverse polarity protection

Noise Level : <40 dB (passive cooling, fanless operation)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry