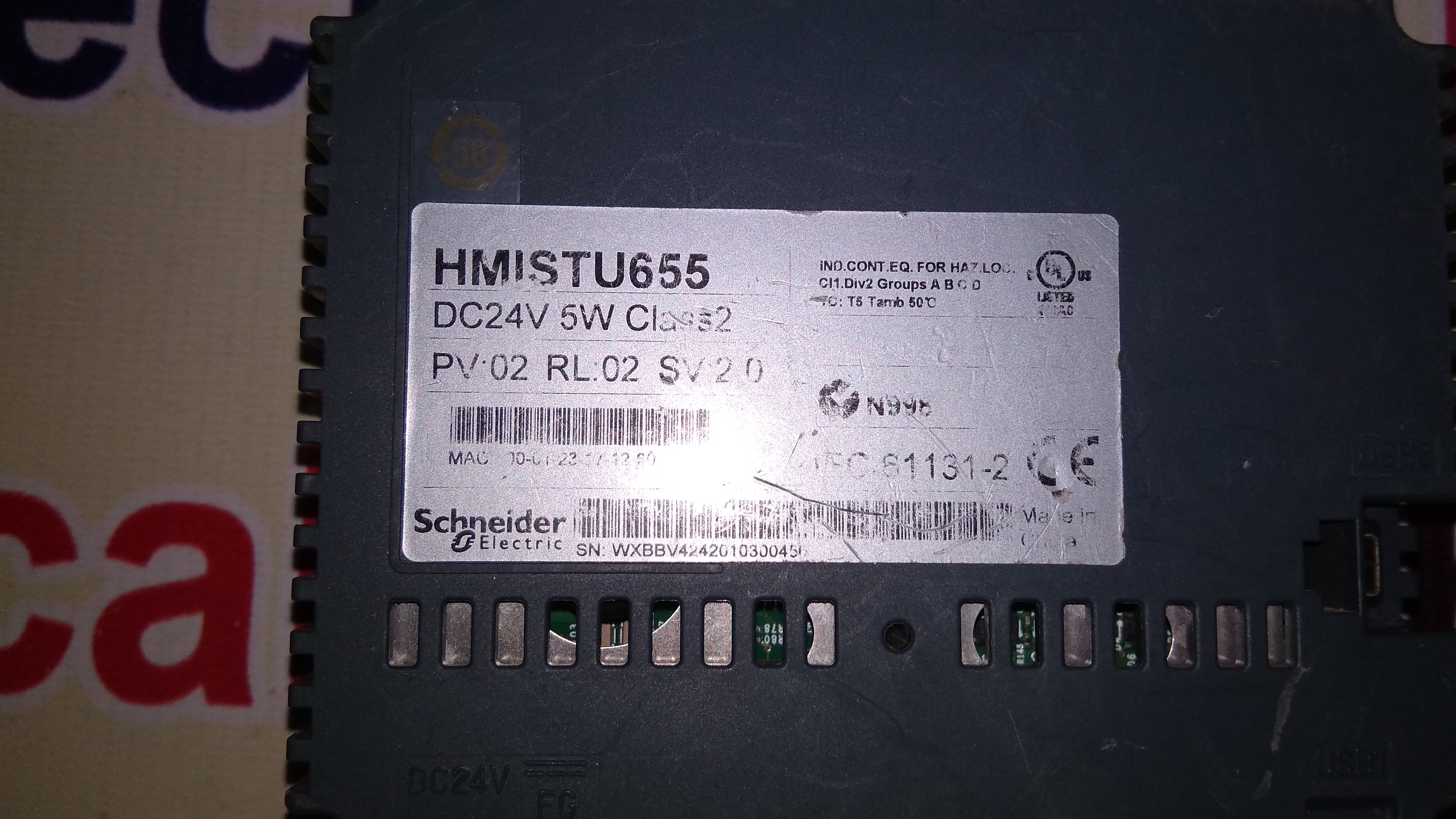

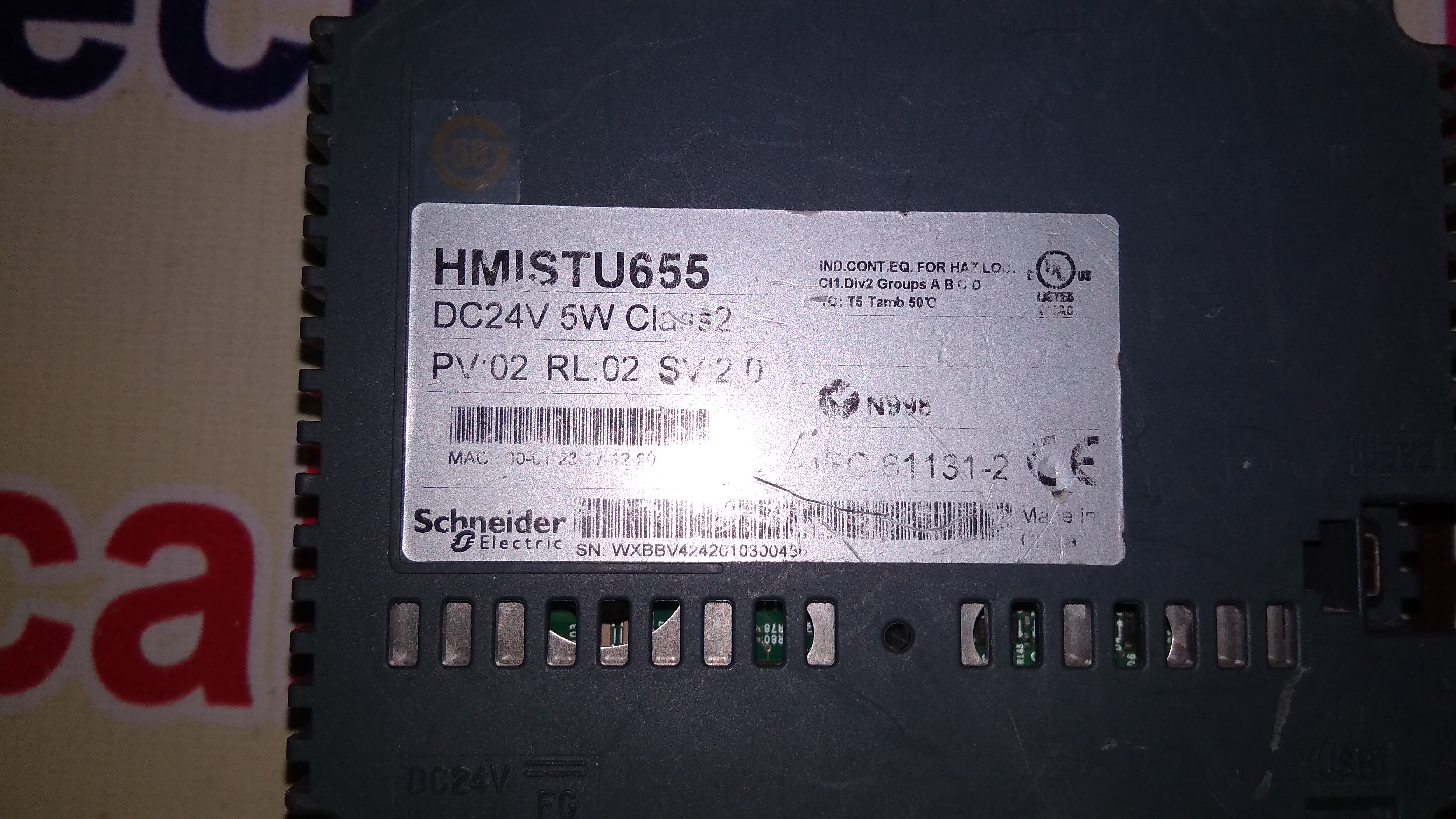

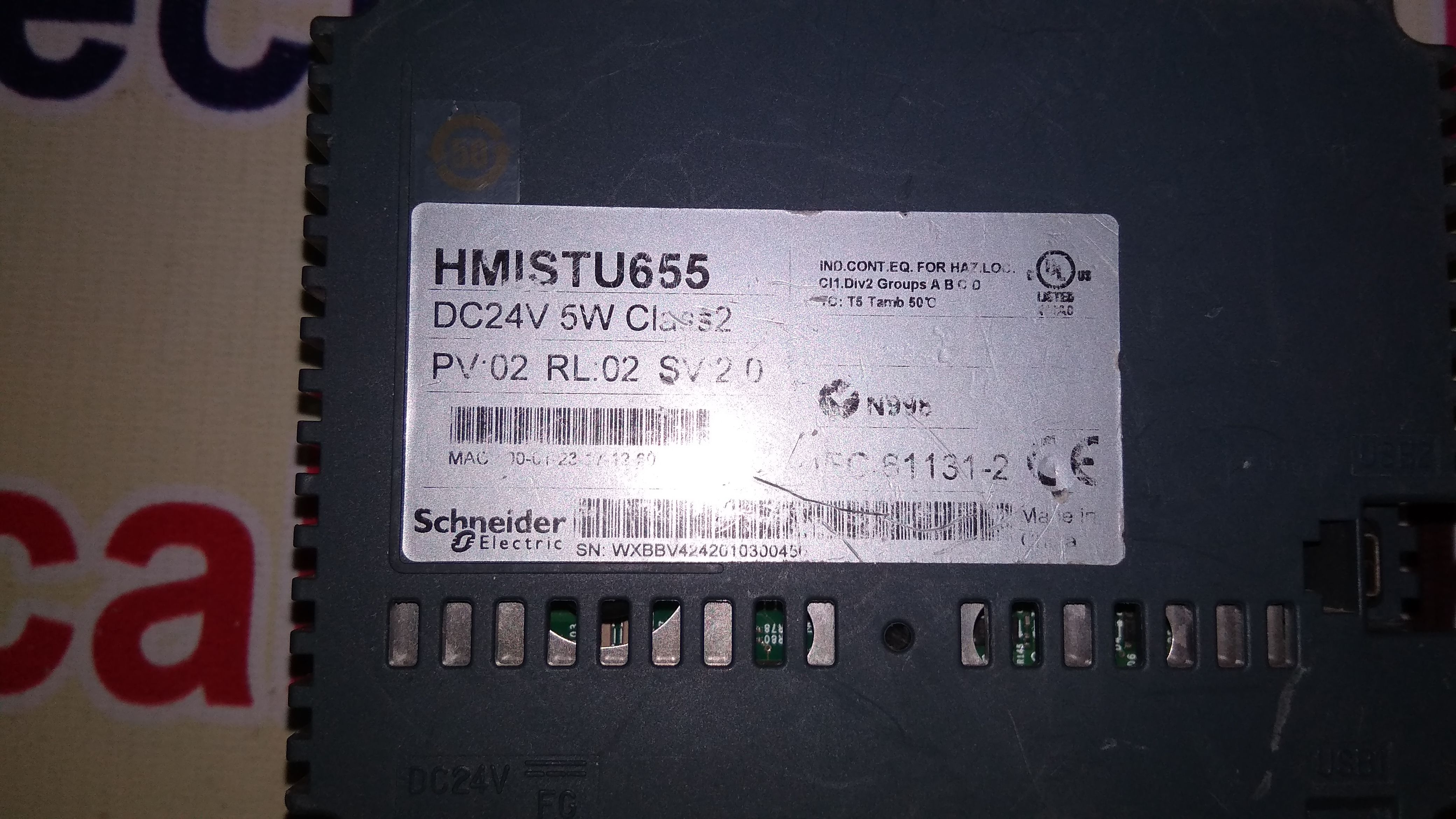

SCHNEIDER HMI

SCHNEIDER HMI Specification

- Features

- Touchscreen, Ethernet/Serial Connectivity, Data Logging, Real-time Monitoring, Alarm Management, Recipe Management, User Management, Password Security

- Rated Power

- 5W to 12W (model dependent)

- Noise Level

- Silent operation (fanless design)

- Working Temperature

- 0C to 50C

- Cooling Method

- Natural air convection (fanless passive cooling)

- Rated Current

- max 1.2A at 24V DC

- Output Type

- Digital Display; Touch Screen Interface

- Operating Temperature

- 0C to 50C

- Connector Type

- Screw terminal for power input; DB9/DB25 for serial, RJ45 for Ethernet

- Power Supply

- 24V DC external supply

- Current Range

- 0.5A to 1.2A (depending on model)

- Application

- Factory automation, Industrial process control, SCADA systems

- Phase

- Single Phase (for panel supply)

- Product Type

- Schneider HMI (Human Machine Interface)

- Output Power

- Not Applicable (Display Device)

- Input Voltage

- 24V DC nominal

- Voltage Protection

- Overvoltage, undervoltage protection circuit

- Efficiency

- Greater than 85%

- Material

- Polycarbonate Housing, Front Panel: Glass Touchscreen

- Storage Temperature

- -20C to +60C

- Weight

- Approx. 1.5 kg

- Connectivity

- Ethernet, RS232, RS485, USB Host/Device

- Protection Rating

- IP65 front panel (dust and water jet protection)

- Display Resolution

- 800 x 480 pixels (common for 7 model)

- Touch Panel Type

- 4-wire resistive touch

- Screen Colors

- 65K (16-bit RGB)

- Mounting Type

- Panel mounting (flush mount)

- Display Size

- 7 inch TFT LCD (model dependent, varies from 4.3 to 15)

- Backlight Life

- Typical 50,000 hours

- Supported Protocols

- Modbus TCP/IP, Modbus RTU, Schneider Electric and third-party PLCs

About SCHNEIDER HMI

Key Features and Applications of SCHNEIDER HMI

The SCHNEIDER HMI boasts advanced features including a touchscreen interface, real-time monitoring, data logging, and robust Ethernet/serial connectivity. Ideal for factory automation, industrial process control, and SCADA systems, this device suits both large-scale and niche operations. With its secure password management and durable glass touchscreen, the HMI supports seamless, efficient usage for operators and engineers ensuring precision and productivity in demanding industrial environments.

Domestic Market, Packaging, and Delivery for SCHNEIDER HMI

SCHNEIDER HMI serves the vast Indian market with reliable availability and premium support. Upon arrival, units are securely packaged to withstand transit, assuring pristine condition at delivery. A focus on quick dispatch ensures minimal lead time from order to shipment. Flexible payment terms cater to diverse business needs, supporting smoother procurement cycles and faster integration into your automation setup.

FAQs of SCHNEIDER HMI:

Q: How is the SCHNEIDER HMI typically used in industrial settings?

A: The SCHNEIDER HMI is designed for integration in factory automation, industrial process controls, and SCADA systems, providing operators real-time monitoring, alarm management, and intuitive process control.Q: What sets the SCHNEIDER HMI apart in terms of connectivity and compatibility?

A: The HMI supports Ethernet, RS232, RS485, and USB connections, and is compatible with Modbus TCP/IP, Modbus RTU, Schneider Electric, and third-party PLCs, giving it exceptional adaptability across automation networks.Q: Where can the SCHNEIDER HMI be installed and operated safely?

A: With an IP65-rated front panel for dust and water jet protection, the unit can be safely panel mounted in harsh industrial environments, working efficiently between 0C and 50C.Q: What is the process for deploying and setting up the SCHNEIDER HMI?

A: Installation involves flush panel mounting, connecting power and communication lines (using screw terminals, DB9/DB25, and RJ45 as required), and configuring protocols for PLC integration. The interface guides you through setup with its touch panel.Q: What are the benefits of choosing the SCHNEIDER HMI for automation projects?

A: Operators benefit from its meritorious real-time monitoring, data logging, alarm management, and efficient touchscreen interface, all underpinned by robust protection and silent, maintenance-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

POWER SUPPLY

Material : Metal Enclosure

Features : High Reliability, Low Ripple, Compact Design

Cooling Method : Natural Air Cooling

Working Temperature : 10C to +60C

Operating Temperature : 10C to +60C

Weight : 520g

SCHNEIDER HMI XBT N200

Material : Undefined

Features : Undefined

Cooling Method : Undefined

Working Temperature : Undefined

Operating Temperature : Undefined

Weight : Undefined

SCHNEIDER MODULE TSXETY5103

Material : Plastic and electronic components

Features : 10/100 Mbps Ethernet, Modbus TCP/IP communication, DIN Rail mountable

Cooling Method : Natural convection

Working Temperature : 0C to +60C

Operating Temperature : 0C to +60C

Weight : Approx. 180 g

SCHNEIDER MODULE TSX DSY 08T22

Material : Plastic and Metal

Features : Compact design Reliable performance

Cooling Method : Air

Working Temperature : 0C to 60C

Operating Temperature : 0C to 60C

Weight : Approximately 150g

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry