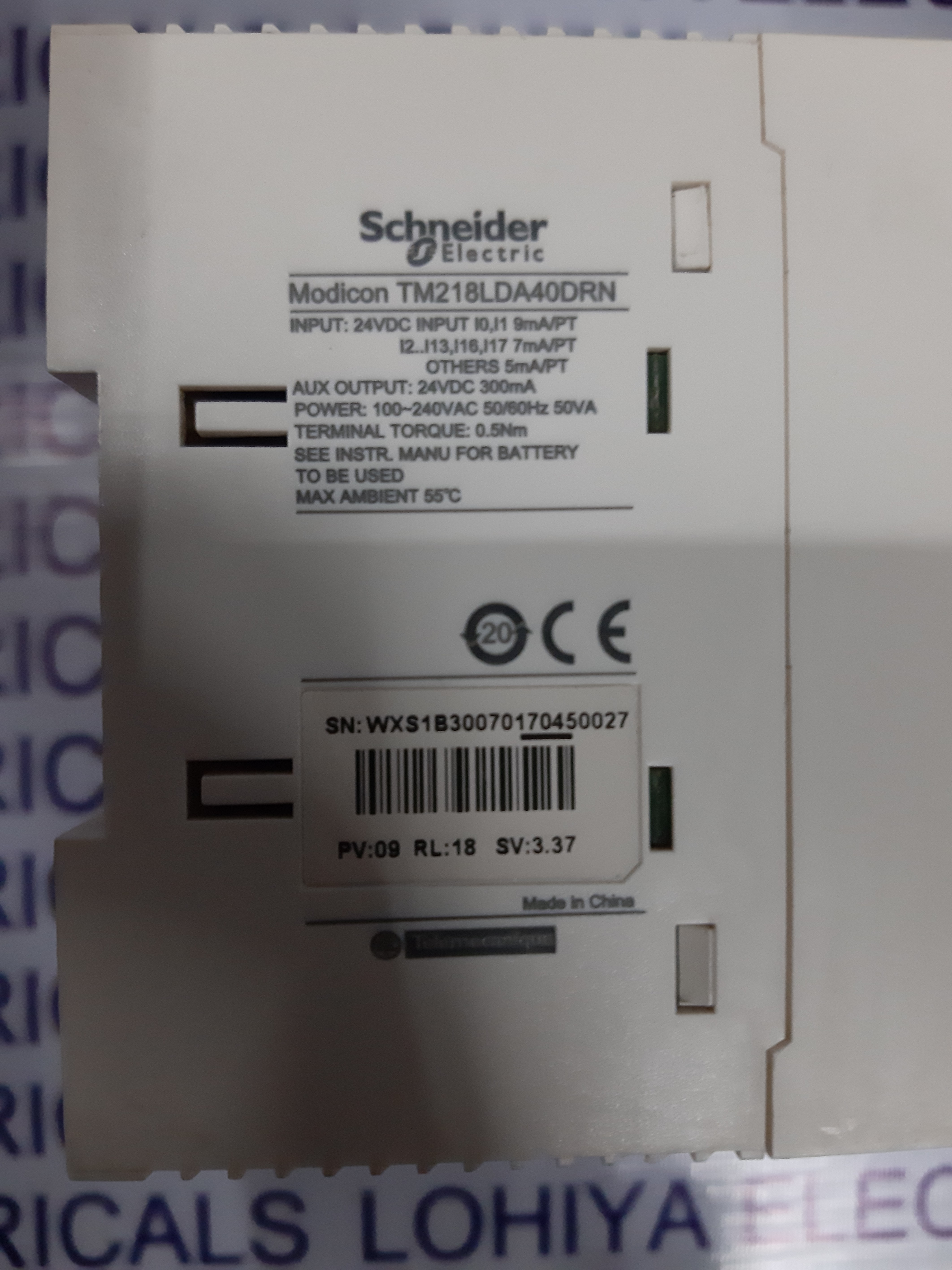

Schneider Electric Plc

Schneider Electric Plc Specification

- Rated Current

- 1A

- Noise Level

- <45 dB

- Cooling Method

- Natural Air Cooling

- Power Factor

- >0.9

- Phase

- Single Phase

- Features

- Password Protection, Expandable Ports, Compact Design, LCD Display

- Working Temperature

- 0C to 55C

- Current Range

- 0.1A - 1A

- Connector Type

- Screw Terminal

- Rated Power

- 20W

- Operating Temperature

- 0C to 55C

- Output Current

- 0.5A/1A (per output channel, model dependent)

- Power Supply

- External power supply required

- Output Type

- Digital/Analog Output (model dependent)

- Application

- Industrial Automation, Process Control, Machine Automation

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- Up to 20W (depending on model)

- Output Frequency

- 50/60Hz

- Input Voltage

- 24V DC / 100-240V AC (model dependent)

- Voltage Protection

- Over-voltage, under-voltage protection

- Efficiency

- >85%

- Material

- Flame Retardant ABS Plastic

- Line Regulation

- <0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 350g

- Communication Interface

- RS232, RS485, Ethernet (model-dependent)

- Display Type

- Optional Digital/LCD Display

- Expansion Ports

- Available for I/O and Communication Modules

- Backup Memory

- EEPROM maintained

- Protection Class

- IP20

- Program Memory

- 8 KB (expandable in certain models)

- Input Type

- Relay & Transistor Inputs

- Mounting Type

- DIN Rail Mounting

- Scan Time

- <2 ms/logic instruction

About Schneider Electric Plc

Schneider Electric PLC: Applications & Competitive Edge

Used by manufacturing, process control, and machine automation industries, the Schneider Electric PLC excels in delivering fast scan times and high efficiency. Its competitive advantages include modular expansion options, password protection for added security, and robust input/output configurations. Capitalising on these strengths, businesses achieve reliable automation across diverse sectors such as packaging, logistics, assembly lines, and resource management, making it a premier choice for modern operations.

Certifications, Logistics & Packaging Information

Schneider Electric PLC products are offered with relevant safety and quality certifications, ensuring adherence to international standards. Shipments are initiated from major Indian FOB ports, with careful packaging to guarantee product integrity during transit. To facilitate client confidence, the company offers sample policies and flexible logistics solutions for prompt deliveries. These measures assure seamless onboarding, allowing customers to assess optimum suitability before integrating the PLC into their workflow.

FAQs of Schneider Electric Plc:

Q: How can I expand the memory and I/O of Schneider Electric PLCs?

A: Certain Schneider Electric PLC models feature expandable program memory and I/O capabilities through available expansion ports for both communication and additional modules.Q: What communication interfaces are supported by this PLC?

A: Depending on the model, Schneider Electric PLCs provide RS232, RS485, and Ethernet interfaces to connect with a wide variety of industrial devices and networks.Q: When is it recommended to use the optional Digital/LCD display?

A: The optional Digital/LCD display is beneficial for immediate monitoring and configuration, particularly in machine automation setups that demand real-time visibility and control.Q: What process ensures protection against voltage fluctuations?

A: Schneider Electric PLCs incorporate over-voltage and under-voltage protection, safeguarding both equipment and processes from electrical inconsistencies and maintaining efficient operations.Q: Where can Schneider Electric PLCs be applied within industrial settings?

A: These PLCs are ideally suited for process control, machine automation, and resource management across manufacturing, packaging, and logistics industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

SCHNEIDER PLC

Cooling Method : Natural Air Cooling

Weight : Approx. 420g

Features : Compact Design, Modular Expansion, Builtin Communication Port, LED Indication

Working Temperature : 0C to +55C

Input Voltage : 100240V AC

Connector Type : Screw Terminal Connector

Schneider CCX17

Cooling Method : Air Cooling

Weight : Approx. 18 kg

Features : Short Circuit Protection, Easy Installation, LED Indicator, High Reliability

Working Temperature : 10 to 55C

Input Voltage : 415 V AC

Connector Type : Screw Terminals

SCHNEIDER MODULE TSX ETY 110

Cooling Method : Passive

Weight : 250g

Features : HighSpeed Processing Stable Communication

Working Temperature : 0C to 55C

Input Voltage : 24V DC

Connector Type : Ethernet

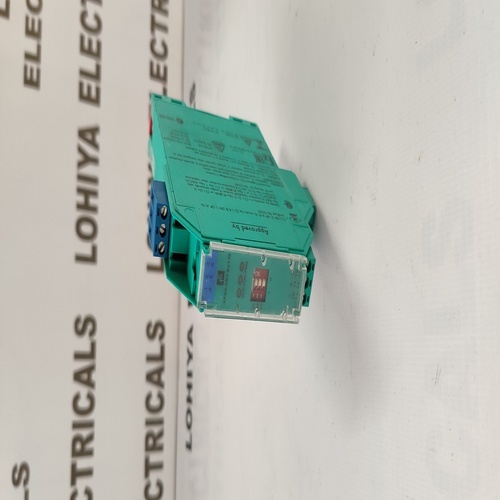

PEPPERL FUCHS KFD2-SR2-EX1.W SWITCH AMPLIFIER

Cooling Method : Natural convection

Weight : Approx. 150 grams

Features : Intrinsic safety, galvanic isolation, compact design, LED status indication

Working Temperature : 20C to +60C

Input Voltage : 18 V DC to 30 V DC

Connector Type : Screw terminals

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry