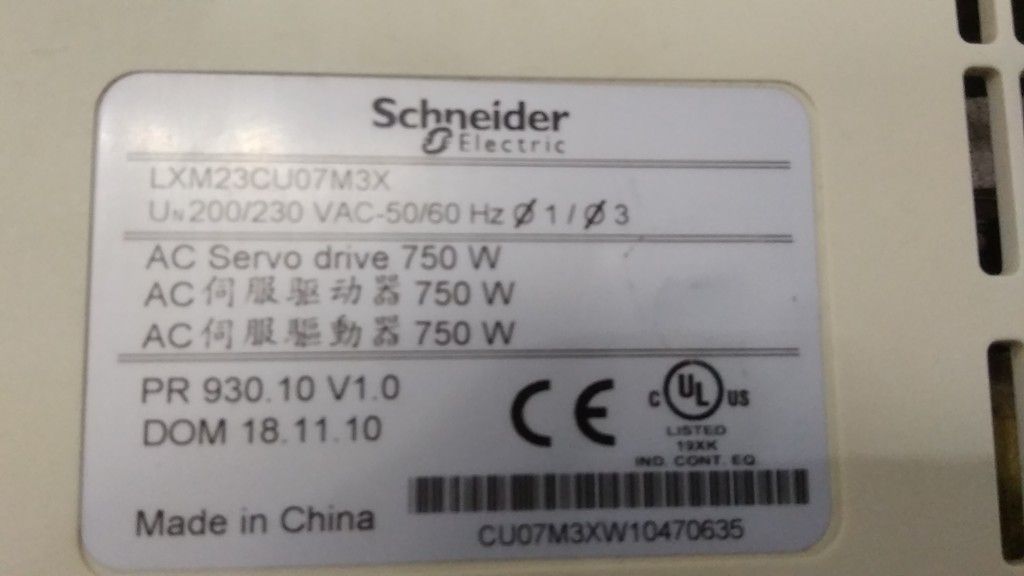

SCHNEIDER AC SERVO DRIVE

SCHNEIDER AC SERVO DRIVE Specification

- Current Range

- 0-4.5 A

- Operating Temperature

- 0C to 55C

- Rated Power

- 750 W

- Cooling Method

- Forced Air Cooling

- Application

- CNC machines, Robotics, Printing machinery, Packaging

- Rated Current

- 4.5 A

- Output Current

- 4.5 A

- Power Supply

- AC 200-240V

- Connector Type

- Screw terminal

- Output Type

- 3 Phase AC

- Power Factor

- >= 0.98

- Phase

- Single/Three Phase

- Working Temperature

- 0C to 55C

- Noise Level

- Less than 60 dB

- Features

- Compact Size, Digital Display, Auto Tuning, Overload Protection

- Product Type

- AC Servo Drive

- Output Power

- 750 W

- Output Frequency

- 0-400 Hz

- Input Voltage

- 200-240V AC, 1/3 Phase

- Voltage Protection

- Overvoltage and undervoltage protection

- Efficiency

- High efficiency (> 90%)

- Material

- Industrial grade ABS enclosure

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 65C

- Weight

- Approx. 2 kg

About SCHNEIDER AC SERVO DRIVE

Versatile Applications and Operators for the SCHNEIDER AC SERVO DRIVE

The SCHNEIDER AC SERVO DRIVE shines in diverse applications including CNC machining, high-precision robotics, printing systems, and intricate packaging machinery. Designed for both metallic and composite surfaces, it adapts to a variety of installation environments. Commonly used by automation engineers, machinery manufacturers, and maintenance professionals, its enviable adaptability ensures optimal performance across different operational media and surfaces, serving as a formidable ally in demanding industrial settings.

FOB Port, Packaging, and Sample Exchange of SCHNEIDER AC SERVO DRIVE

Order completion for the SCHNEIDER AC SERVO DRIVE is smooth for global clients via leading FOB ports, ensuring swift and secure shipments. Each drive is packaged meticulously to guarantee its pristine condition upon arrival. If you wish to evaluate before committing, samples are available for qualifying requests. Our competitive rate structure allows for flexible transactions and valuable exchanges, enabling you to trial and adopt top-tier innovation with complete confidence.

FAQs of SCHNEIDER AC SERVO DRIVE:

Q: How does the SCHNEIDER AC SERVO DRIVE support high-precision operations?

A: The drive utilizes field-oriented vector control and high frequency accuracy (0.01%) to deliver formidable precision, making it ideal for processes requiring highly accurate speed and position control such as CNC machining and robotics.Q: What applications can benefit most from this servo drive?

A: Industries including CNC machinery, robotics, printing, and high-speed packaging lines stand to gain the most from this drives enviable efficiency, reliability, and advanced control features.Q: Where is the ideal surface or environment for installing the SCHNEIDER AC SERVO DRIVE?

A: The drive is designed for panel mount installations and an IP20 rating, suitable for clean and controlled industrial environments with altitudes under 1000m and temperatures from 0C to 55C.Q: When can I expect delivery after placing an order for this AC servo drive?

A: Delivery timelines are linked to order completion terms and the chosen FOB port. Shipments are processed swiftly and securely, with packaging assuring safe transit to your location.Q: What is the process to request a sample before completing an order?

A: Simply contact the supplier to express your interest in a sample. Upon verification and agreement on rate, an exchange can be arranged so you can test product suitability ahead of full order placement.Q: How does the built-in braking unit enhance usage safety?

A: The integrated dynamic braking circuit allows for rapid deceleration and secure stopping of motors, ensuring safer operation during emergency stops or sudden load changes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

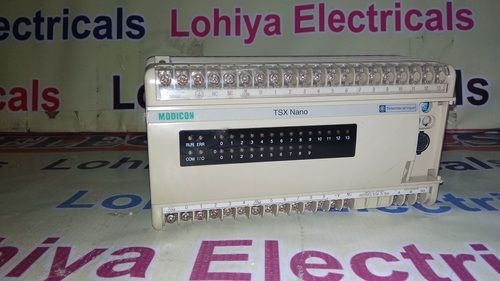

Schneider PLC

Power Supply : AC Powered

Connector Type : Screw Terminal

Product Type : Schneider PLC (Programmable Logic Controller)

Cooling Method : Natural Air Cooling

Application : Industrial Automation, Process Control

Operating Temperature : 0C to 55C

SCHNEIDER QUANTUM

Power Supply : External, depends on selected module

Connector Type : Removable terminal blocks and standard I/O connectors

Product Type : Programmable Logic Controller (PLC)

Cooling Method : Passive cooling (natural convection)

Application : Factory Automation, Process Control, SCADA Systems

Operating Temperature : 0C to +60C

SCHNEIDER PLC

Power Supply : AC Supply

Connector Type : Removable Terminal Blocks

Product Type : PLC (Programmable Logic Controller)

Cooling Method : Natural Air Cooling

Application : Industrial Automation, Process Control

Operating Temperature : 0C to +55C

TSX QUANTUM CPU 140 CPS 111 00

Power Supply : Internal

Connector Type : Standard Connector

Product Type : PLC CPU Module

Cooling Method : Integrated Fan

Application : Industrial Automation

Operating Temperature : 0C to 60C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry