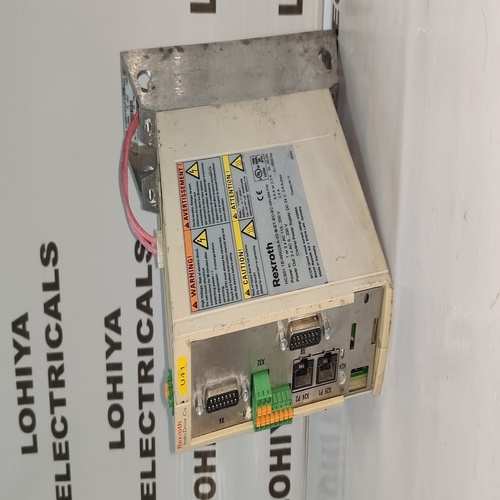

REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE

REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE Specification

- Rated Current

- 13.5 A

- Operating Temperature

- 0C to +40C

- Application

- Industrial Automation, CNC Machines, Robotics

- Power Supply

- AC Supply

- Power Factor

- >=0.95

- Features

- Integrated Safety, Compact Design, High Dynamic Response

- Output Current

- 15.2 A (Max)

- Current Range

- 0-15.2 A

- Noise Level

- <65 dB

- Connector Type

- Pluggable Connectors

- Rated Power

- 7 kW

- Output Type

- Digital/Analog

- Cooling Method

- Forced Air Cooling

- Phase

- Three Phase

- Working Temperature

- 0C to +40C

- Product Type

- Servo Drive

- Output Power

- 7 kW

- Output Frequency

- 0-599 Hz

- Input Voltage

- 3 x 380-480 V AC, 50/60 Hz

- Voltage Protection

- Overvoltage and Undervoltage Protection

- Efficiency

- Up to 96%

- Material

- Metallic Enclosure

- Line Regulation

- 0.1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 13 kg

- Braking Function

- Integrated Braking Chopper

- IP Rating

- IP20

- Mounting Type

- Panel Mount

- Control Method

- Vector Control / Servo Control

- Display

- LED Display

- Communication Interface

- Ethernet, CANopen, PROFIBUS, SERCOS

- Model Number

- HLC01 1C-02M4-A-007-NNNN

- Software Support

- Rexroth IndraWorks

- Feedback Supported

- Resolver and Encoder

About REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE

Versatile Applications and Superior Advantages

The REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE seamlessly fits diverse technical ecosystems, not just CNC machines and robotics, but also packaging, printing, and assembly lines. Its compact design allows easy integration on various mounting surfaces while supporting both digital and analog outputs. The integrated safety features and robust IP20 rating ensure smooth operation. Users gain unmatched flexibility and reliability, maximizing efficiency and extending the life of critical equipment.

Export Features, Value Exchange, and Packaging

Offered via major FOB ports, the REXROTH HLC01 1C-02M4-A-007-NNNN boasts impressive market value across Europe, Asia, and the Americas. Carefully packaged with protective materials for a seamless handover and safe transport during exchange, each unit is delivered with complete documentation. Rexroths reputation ensures trusted import and export processes, enhancing user experience and maintaining product integrity for global markets.

FAQs of REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE:

Q: How is the REXROTH HLC01 1C-02M4-A-007-NNNN SERVO DRIVE installed?

A: The servo drive features a panel mount installation, using pluggable connectors for straightforward setup and compatibility within various industrial control panels.Q: What types of feedback does this servo drive support?

A: It supports both resolver and encoder feedback, optimizing performance and precision for advanced automation applications.Q: When should I use the integrated braking chopper?

A: The integrated braking chopper is essential for applications requiring rapid stops or precise torque control, ensuring safe and efficient deceleration.Q: Where can the servo drive be applied beyond CNC machines?

A: You can utilize this servo drive in industrial automation, robotics, packaging, assembly, and printing machines for high-precision control.Q: What is the process for exchanging or exporting the servo drive?

A: Units are meticulously packaged and handed over at major FOB ports, complying with international shipment procedures for safe and secure delivery.Q: How does the servo drive provide benefits in efficiency and safety?

A: With up to 96% efficiency and integrated safety functions, users enjoy reduced energy consumption, superior dynamic response, and reliable, secure operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in REXROTH Used SERVO DRIVE AC DRIVE Category

Rexroth HVR02.2W010N -

Connector Type : Terminal Block

Product Type : Power Supply Module

Output Frequency : 50/60 Hz

Noise Level : <65 dB(A)

Features : Fan Cooling, LED Status Indicators, Maintenance Friendly

Output Current : 22 A

REXROTH DKCXX3.3-016-7 SERVO DRIVE

Connector Type : Screw Terminal

Product Type : Servo Drive

Output Frequency : 0500 Hz

Noise Level : < 65 dB(A)

Features : Digital Communication, Programmable, Diagnostic Functions, Overload Protection

Output Current : Rated 32 A

REXROTH HCS01.1E-W0009-A-02-B-ET-EC-EC-NN-NN-FW SERVO DRIVE

Connector Type : Screw Terminal, Plugin Connectors

Product Type : Servo Drive

Output Frequency : 0500 Hz

Noise Level : <60 dB

Features : Compact Design, Integrated Safety, Advanced Diagnostics

Output Current : 9 A

Rexroth DKC01.3-100-

Connector Type : Standard connector

Product Type : Servo drive

Output Frequency : Variable up to 500 Hz

Noise Level : Low

Features : Compact design high precision

Output Current : Up to 100A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry