Call:

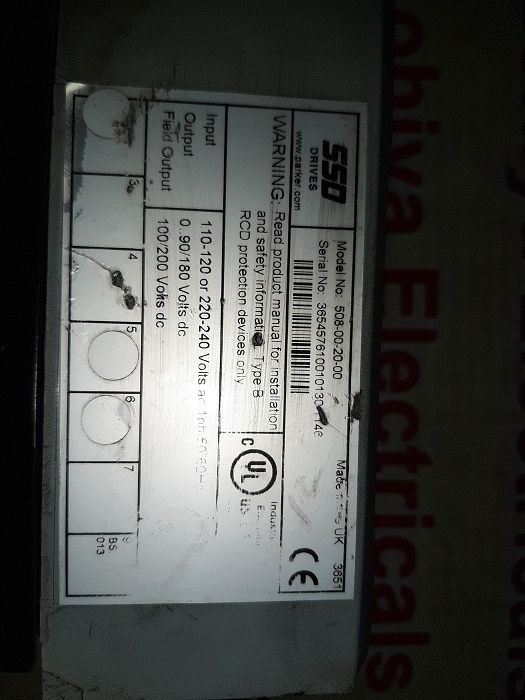

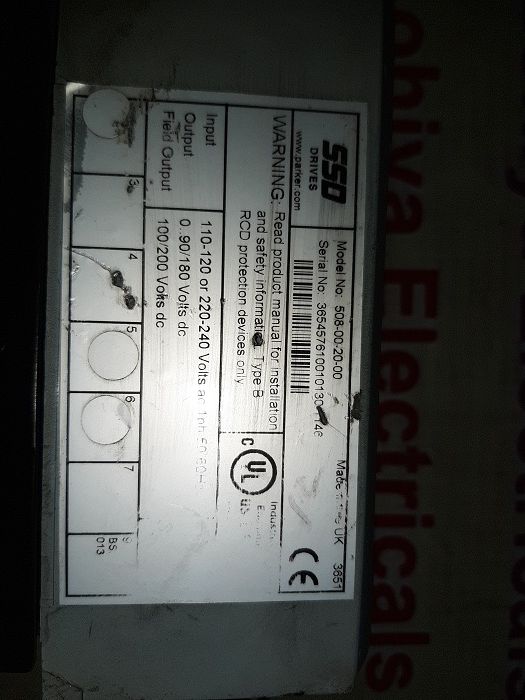

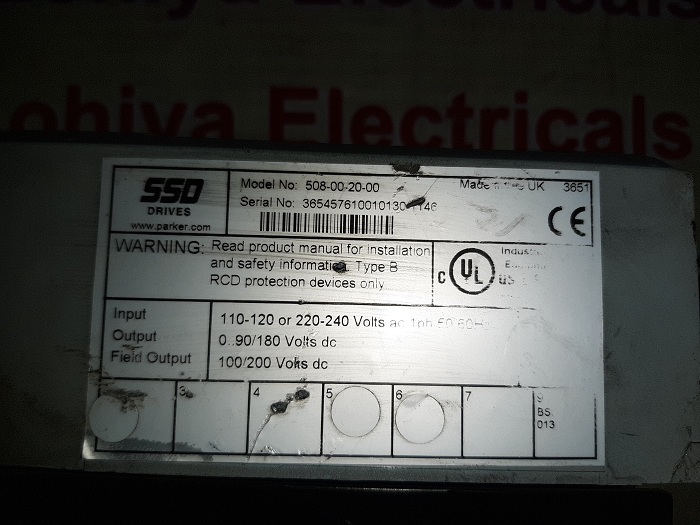

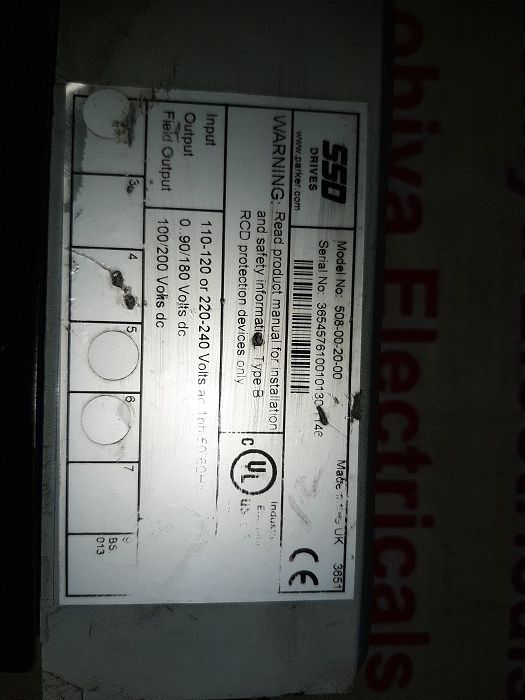

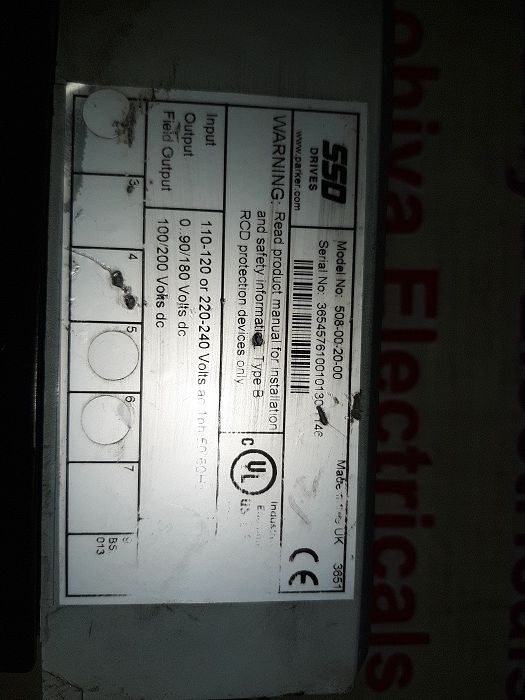

PARKER DRIVVE

PARKER DRIVVE Specification

- Noise Level

- <60 dB

- Features

- Digital Display, Overload Protection, Soft Start

- Output Current

- 5.6A

- Operating Temperature

- -10C to 50C

- Power Factor

- >0.98

- Output Type

- Three Phase

- Rated Current

- 5.6A

- Application

- Pumps, Fans, Conveyor Systems

- Current Range

- 2A - 8A

- Cooling Method

- Forced Air

- Power Supply

- AC

- Connector Type

- Screw Terminal

- Phase

- Three Phase

- Working Temperature

- -10C to 50C

- Rated Power

- 2.2 kW

- Product Type

- AC Drive

- Output Power

- 2.2 kW

- Output Frequency

- 0 - 400 Hz

- Input Voltage

- 380V - 480V AC

- Voltage Protection

- Overvoltage, Undervoltage, Short Circuit

- Efficiency

- 98%

- Material

- Aluminum Alloy

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 60C

- Weight

- 2.6 kg

- Insulation Voltage

- 1500V AC

- Control Mode

- V/F Control, Sensorless Vector Control

- Altitude Range

- 1000m

- Start-up Torque

- 150% at 1 Hz

- Protection Class

- IP20

- Braking Unit

- Built-in

- Frequency Setting

- Analog and Digital

- Humidity

- 95% RH (non-condensing)

- Communication Ports

- RS485 Modbus

- Mounting Type

- Panel Mount

- Display Type

- LED Digital Panel

About PARKER DRIVVE

Introducing the Featured and Acclaimed PARKER DRIVVEan esteemed, prodigious drive solution designed for uncompromising performance. This first-rate, world-class device features versatile V/F Control and Sensorless Vector Control, making it ideal for demanding applications such as pumps, fans, and conveyor systems. It boasts a sturdy IP20 aluminum alloy build, intuitive LED digital panel, and advanced protections including overvoltage, undervoltage, and short circuit. With a built-in braking unit, soft start, efficiency as high as 98%, and RS485 Modbus connectivity, grab yours now for unparalleled reliability and control!

Versatile Applications across Industrial Plants

PARKER DRIVVE is tailored for seamless integration in various plant operations, excelling in the control of pumps, fans, and conveyor systems. Engineered with a flexible mounting system and robust protection features, it adapts to different areas within manufacturing plants, processing facilities, or material handling sites. Designed to thrive at altitudes up to 1000m and operating reliably in tough plant conditions, it is the optimal choice for continuous, high-performance site operation.

Certifications, Delivery, and Sample Policy Information

PARKER DRIVVE is manufactured to meet strict market value standards to ensure quality and durability. Goods are carefully transported with secure packing and prompt dispatch, promising efficient delivery to your facility. Our delivery time aligns with industry practice for fast turnaround, and we support customers needs by offering a flexible sample policy, enabling comprehensive evaluation before procurement. Each unit is packed to guarantee safe transit, preserving the world-class performance you expect.

Versatile Applications across Industrial Plants

PARKER DRIVVE is tailored for seamless integration in various plant operations, excelling in the control of pumps, fans, and conveyor systems. Engineered with a flexible mounting system and robust protection features, it adapts to different areas within manufacturing plants, processing facilities, or material handling sites. Designed to thrive at altitudes up to 1000m and operating reliably in tough plant conditions, it is the optimal choice for continuous, high-performance site operation.

Certifications, Delivery, and Sample Policy Information

PARKER DRIVVE is manufactured to meet strict market value standards to ensure quality and durability. Goods are carefully transported with secure packing and prompt dispatch, promising efficient delivery to your facility. Our delivery time aligns with industry practice for fast turnaround, and we support customers needs by offering a flexible sample policy, enabling comprehensive evaluation before procurement. Each unit is packed to guarantee safe transit, preserving the world-class performance you expect.

FAQs of PARKER DRIVVE:

Q: How does the PARKER DRIVVE enhance the performance of pumps and conveyor systems?

A: The PARKER DRIVVE utilizes advanced V/F Control and Sensorless Vector Control to deliver precise speed and torque adjustments. This results in efficient, reliable operation for pumps, fans, and conveyor systems, improving system responsiveness, energy savings, and equipment longevity.Q: What environmental conditions can the PARKER DRIVVE operate in?

A: It is designed for tough environments, operating between -10C to 50C, withstanding humidity levels up to 95% non-condensing, and functioning reliably at altitudes up to 1000m. Its IP20 protection class ensures resistance to dust and accidental contact.Q: Where can the PARKER DRIVVE be installed within an industrial facility?

A: With its panel mounting design and compact build, the PARKER DRIVVE can be efficiently installed in electrical control panels throughout various areas of a plant, including production lines, pump stations, and ventilation systems.Q: What is the benefit of the built-in braking unit and soft start feature?

A: The built-in braking unit ensures rapid stopping capabilities without external hardware, enhancing safety and equipment protection. The soft start feature gradually accelerates the motor, reducing mechanical stress and extending the lifespan of the application.Q: How is delivery managed and what is the sample policy for the PARKER DRIVVE?

A: Delivery is efficiently managed through secure packing and prompt dispatch, ensuring your goods arrive safely and on schedule. A flexible sample policy is available, allowing customers to evaluate the product performance before making a purchase decision.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PARKER DRIVE Category

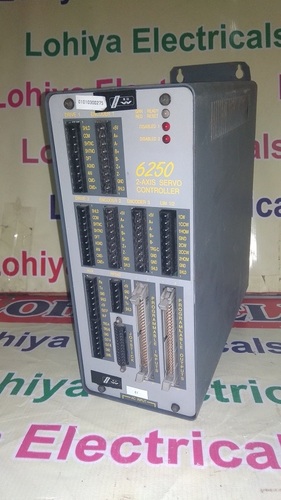

PARKER 631/004/230/F/00 SERVO DRIVE

Minimum Order Quantity : 1 Piece

Noise Level : <54 dB

Line Regulation : 0.5%

Operating Temperature : 0C to 40C

Storage Temperature : 25C to 70C

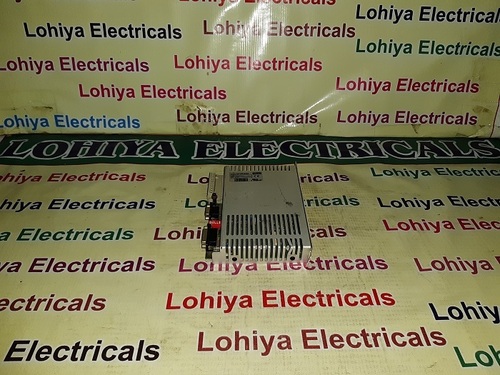

PARKER DRIVE 690PF/0550/400/0011/UK/0/0/0/0/0/230/0

Noise Level : Low Noise

Line Regulation : Stable

Operating Temperature : 0C to 50C

Storage Temperature : 20C to 70C

PARKER SERVO CONTROLLER

Noise Level : < 55 dB

Line Regulation : 0.5%

Operating Temperature : 0C to +55C

Storage Temperature : 20C to +70C

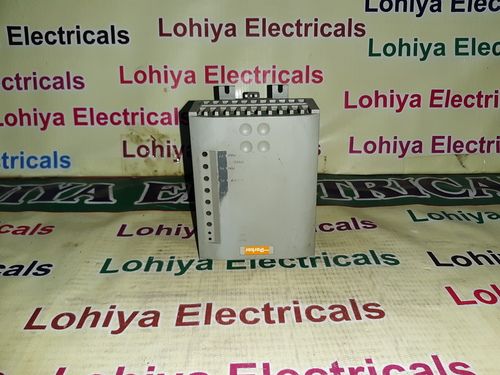

PARKER HANNIFIN S.P.A. DRIVE

Noise Level : <65 dB

Line Regulation : <1%

Operating Temperature : 10C to +50C

Storage Temperature : 40C to +70C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry