PARKER DRIVE

PARKER DRIVE Specification

- Rated Current

- Based on Model

- Features

- Digital Keypad, Auto Tuning, Built-in PID, Compact Design

- Working Temperature

- -10C to +50C

- Power Factor

- >= 0.95

- Current Range

- 1.6A to 35A

- Phase

- Single Phase / Three Phase

- Noise Level

- <65 dB(A)

- Operating Temperature

- -10C to +50C

- Power Supply

- AC

- Rated Power

- Depend on Model (0.37 kW 15 kW)

- Cooling Method

- Cooling Fan

- Output Current

- Up to 35A

- Output Type

- Adjustable, Digital Display

- Application

- Industrial Automation, Conveyor Systems, Pumps, Fans

- Connector Type

- Terminal Block

- Product Type

- Parker Drive (Variable Frequency Drive)

- Output Power

- 0.37 kW to 15 kW

- Output Frequency

- 0.5 Hz to 400 Hz

- Input Voltage

- 220V / 380V AC (Single & Three Phase)

- Voltage Protection

- Over Voltage & Under Voltage Protection

- Efficiency

- Over 90%

- Material

- High Grade Engineering Plastic & Metal

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 2.5 kg (varies per model)

- Frequency Setting

- Keypad, Potentiometer, External Signals

- Protection Features

- Short Circuit, Overload, Overheat, Stall Prevention

- Control Method

- V/F Control, Sensorless Vector Control

- Display Type

- LED Digital Display

- Communication Interface

- RS485 (Modbus)

- Ingress Protection

- IP20 Standard

- Mounting Type

- Panel Mount

- Humidity

- 5% to 95% (Non-Condensing)

- Acceleration/Deceleration Time

- 0.1 to 9999 sec

About PARKER DRIVE

PARKER DRIVE: Superior Advantage and Versatile Application

PARKER DRIVE stands out by offering advanced auto-tuning and a built-in PID for seamless integration. Its digital keypad allows effortless frequency setting via keypad, potentiometer, or external signals, catering to both specific industrial automation needs and general factory uses. Designed for panel mounting, it suits conveyor systems, pumps, and fans, providing dependable performance and flexible operation within a comprehensive current and power range.

Export Logistics: FOB Port, Packaging, and Export Markets

PARKER DRIVE products are available for quotation with prompt dispatching from major FOB ports. Packaging details ensure safe drop-off, typically featuring robust industrial-grade boxes that protect components during transit. Our main export markets include Asia, the Middle East, and Europe, meeting diverse industrial requirements across continents, and facilitating smooth delivery to clients worldwide through established logistics channels.

FAQs of PARKER DRIVE:

Q: How is PARKER DRIVE installed and what type of mounting does it support?

A: PARKER DRIVE is designed for simple and secure panel mounting, enabling easy integration into existing control systems or new installations.Q: What are the main protection features included in PARKER DRIVE for safety?

A: This drive comes equipped with short circuit, overload, overheat, and stall prevention, along with over voltage and under voltage protection for reliable operation.Q: When should the acceleration and deceleration times be adjusted in PARKER DRIVE?

A: Adjustment of acceleration and deceleration timesranging from 0.1 to 9999 secondsis recommended to suit the mechanical and operational requirements of your application for smooth and efficient performance.Q: Where can PARKER DRIVE be used effectively?

A: PARKER DRIVE is ideal for use in industrial automation, such as conveyor systems, pumps, and ventilation fans, as well as other general industrial applications.Q: What are the communication and display interfaces on PARKER DRIVE?

A: The drive features an RS485 (Modbus) communication interface and a digital LED display, making monitoring and control both efficient and straightforward.Q: How does using PARKER DRIVE benefit industrial operations?

A: PARKER DRIVE enhances efficiency with over 90% operating performance, reliable protection features, flexible input options, and easy configurationdelivering great value and long-term operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PARKER DRIVE Category

PARKER 890SD-532100B0-B00-1A000 AC INVERTER DRIVE

Minimum Order Quantity : 1 Piece

Rated Current : 532 A

Features : Intelligent Programming, Robust Construction, UserFriendly Interface, Digital Displays, Communication Options

Product Type : AC Inverter Drive

Input Voltage : 400 V AC (+/10%)

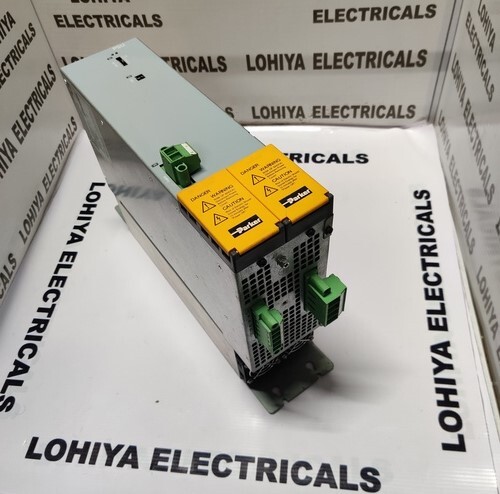

PARKER PSUP20D6USBM00 DRIVE POWER SUPPLY

Minimum Order Quantity : 1 Piece

Rated Current : 1.67A

Features : Compact, Reliable, High Performance

Product Type : Drive Power Supply

Input Voltage : 85264V AC

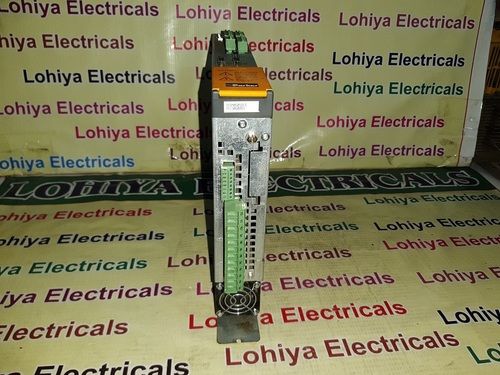

PARKER POWER SERVO DRIVE

Rated Current : 2 A to 45 A (model dependent)

Features : Overload Protection, Compact Design, Digital Display, Autotuning, Position, Speed, and Torque Control

Product Type : Servo Drive

Input Voltage : 200480V AC, 3phase

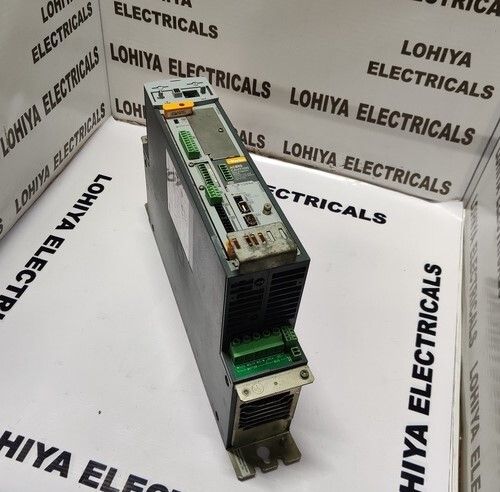

Parker / Compumotor AR-08AE Aries Servo Motor Drive

Rated Current : 4.5 A

Features : Compact Design, HighPerformance Servo Control, LED Status Indicators, Multiple Communication Options, Overload Protection

Product Type : Servo Motor Drive

Input Voltage : 120/240 VAC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry