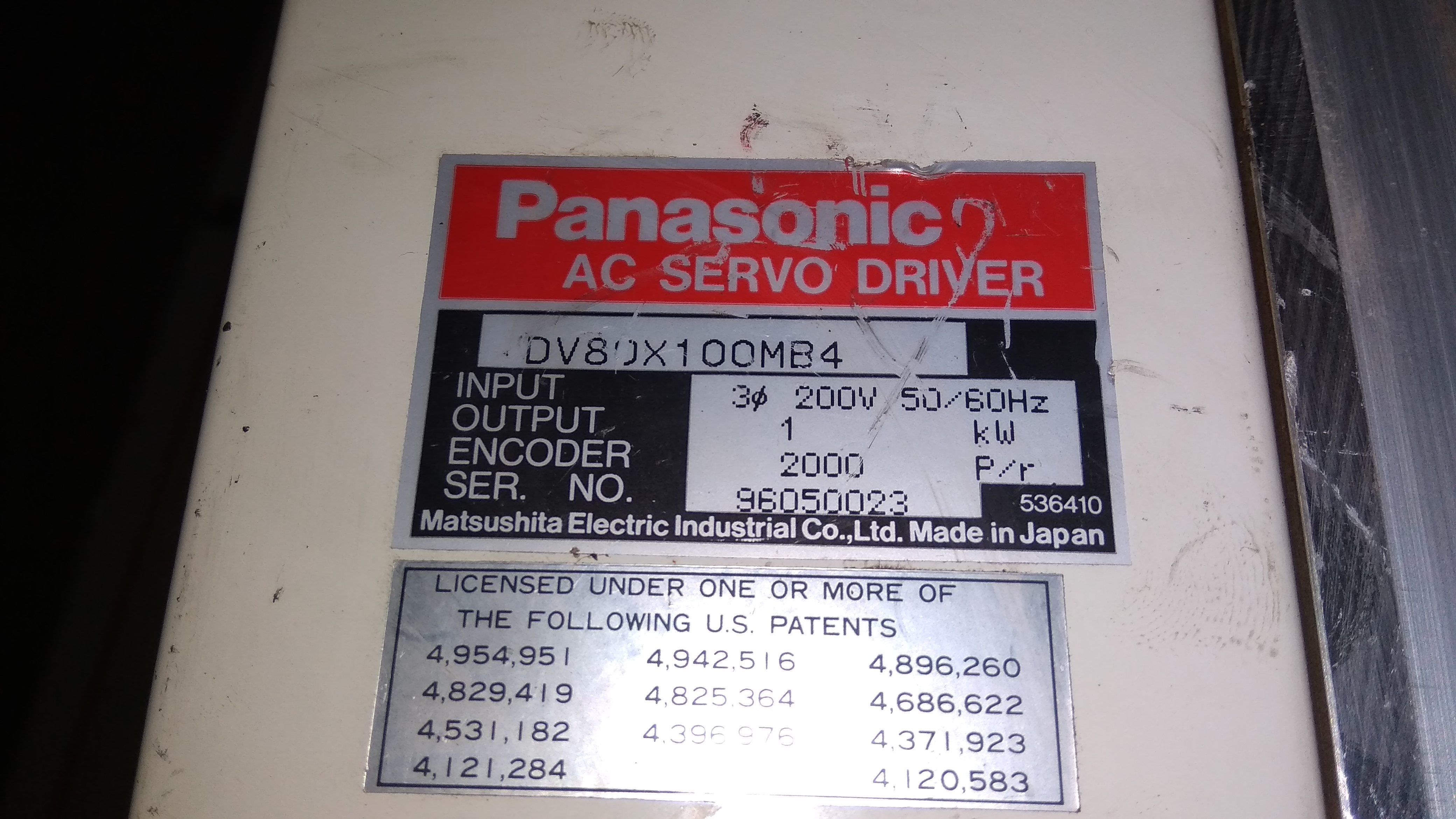

PANASONIC SERVO DRIVE

PANASONIC SERVO DRIVE Specification

- Surface Finish

- Anodized

- Overheating Protection

- YES

- Operating Temperature

- 0C to 55C

- Efficiency

- >92%

- Insulation Material

- Heat-resistant Polymer

- Shape

- Rectangular

- Power Factor

- >0.95

- Humidity %

- 20% 85% (non-condensing)

- IP Rating

- IP20

- Connector Type

- Terminal Block

- Feature

- High Accuracy Positioning, Fast Response

- Mounting Type

- Panel Mount

- Product Type

- Servo Drive

- Application

- Industrial Automation, Robotics, CNC Machinery

- Protection Level

- IP20

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 200-240V AC

- Energy Consumption

- Low

- Output Type

- Analog / Digital

- Color

- Silver & Black

- Dimension (L*W*H)

- 180mm x 80mm x 170mm

- Weight

- 3.5 kg

- Phase

- Three Phase

- Input Voltage

- 200-240V AC

- Size

- Standard

- No Of Poles

- 4

- Material

- Aluminum Alloy

- Connection Type

- Screw Terminal

- Cooling Method

- Natural Air Cooling

- Motor Compatibility

- Rotary / Linear Servo Motors

- Display

- Status LED Indicator

- Braking Function

- Dynamic & Regenerative Braking

- Maximum Output Current

- 5A

- Communication Interface

- RS485, Modbus, CANopen (optional)

- Noise Level

- <55 dB

- Encoder Feedback

- Incremental / Absolute Supported

- Control Method

- Vector Control / Position, Speed, Torque Control

- Ambient Storage Temperature

- -20°C to 65°C

About PANASONIC SERVO DRIVE

Elite Solutions for Precision Machinery

The PANASONIC SERVO DRIVE is widely used for industrial automation, robotics, and precise CNC machinery due to its superior accuracy positioning and fast response capability. Its robust, anodized aluminum alloy structure makes it highly suitable for high-demand applications on various operational surfaces, ensuring longevity and consistent performance. The primary advantage lies in its compatibility with both rotary and linear servo motors, dynamic braking function, and advanced communication interfaces for seamless industrial integration.

Payment & Export: Fast Logistics and Special Rates

Enjoy competitive payment terms and efficient logistics when you choose the PANASONIC SERVO DRIVE. Packaging is carefully designed to protect the equipment during transit and ensures it arrives in perfect condition. Main export markets include Europe, Asia, and the Americas, with delivery estimates provided promptly upon order confirmation. Special rates and expedited shipping are available for bulk orders, giving international customers an unbeatable advantage in sourcing elite automation solutions.

FAQs of PANASONIC SERVO DRIVE:

Q: How does the PANASONIC SERVO DRIVE support different motor types?

A: The servo drive is compatible with both rotary and linear servo motors, ensuring flexibility across multiple industrial and automation settings. It features advanced vector control for precise management of position, speed, and torque.Q: What applications are ideal for this servo drive?

A: The drive is designed for elite use in industrial automation, robotics, and CNC machinery which demand high accuracy, fast response times, and robust performance under challenging conditions.Q: When is dynamic and regenerative braking utilized in usage?

A: Dynamic and regenerative braking are automatically engaged during rapid deceleration or load changes, enhancing safety, reducing energy consumption, and improving overall efficiency in industrial processes.Q: What communication interfaces does the servo drive offer?

A: It comes standard with RS485 and Modbus connectivity, with CANopen available as an optional feature, allowing seamless integration into diverse automation networks.Q: Where is the optimal installation environment for the servo drive?

A: The device performs best when panel-mounted in controlled environments with temperatures ranging from 0C to 55C and humidity between 20% and 85% (non-condensing), ensuring reliable operation and long service life.Q: How does the drive benefit energy consumption and noise levels?

A: With an efficiency greater than 92% and a noise level below 55 dB, the PANASONIC SERVO DRIVE ensures low energy consumption and quiet functioning, making it ideal for environments where both performance and comfort matter.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PANASONIC Used SERVO DRIVE SERVO MOTOR Category

PANASONIC SERVO MOTOR MSMA042A1E

Product Type : AC Servo Motor

Protection Level : IP65

Phase : Three Phase

Energy Consumption : Low

No Of Poles : 8 Poles

Insulation Material : Class F

PANASONIC 3 PHASE MOTOR M9MZ90G4YGA

Product Type : Induction Motor

Protection Level : Other, High

Phase : Three Phase

Energy Consumption : Low

No Of Poles : 4

Insulation Material : Class B

PANASONIC SERVO DRIVE

Product Type : Servo Drive

Protection Level : Other, Short circuit, Overload, Overvoltage Protection

Phase : Single Phase / Three Phase (depending on model)

Energy Consumption : High Efficiency, Low Power Consumption

No Of Poles : Varies by model (typically 2 or 4)

Insulation Material : Highgrade Composite

PANASONIC SERVO DERIVE

Product Type : Servo Drive

Protection Level : IP65

Phase : Three Phase

Energy Consumption : Low

No Of Poles : 4

Insulation Material : Class F Insulation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry