PAC SERVO DRIVE

PAC SERVO DRIVE Specification

- Rated Power

- 400W

- Operating Temperature

- 0C to 50C

- Current Range

- 0 - 5A

- Application

- Industrial Automation, Robotics, CNC Machinery

- Features

- High Response Speed, Precise Position Control, Overload Protection

- Noise Level

- 50 dB

- Output Current

- 2.5A

- Power Supply

- AC Input (220V/380V)

- Connector Type

- Screw Terminal / Plug-in Terminal

- Working Temperature

- 0C - 50C

- Cooling Method

- Forced Air Cooling

- Output Type

- PWM Controlled, Analog & Digital Output

- Power Factor

- >0.95

- Phase

- Single Phase / Three Phase

- Rated Current

- 2.5A

- Product Type

- PAC Servo Drive

- Output Power

- 400W

- Output Frequency

- 0 - 500 Hz

- Input Voltage

- 220V AC Single Phase / 380V AC Three Phase

- Voltage Protection

- Over Voltage, Under Voltage, Over Current, Overload

- Efficiency

- 95%

- Material

- Industrial Grade ABS & Metal Enclosure

- Line Regulation

- 0.5%

- Storage Temperature

- -20C to 70C

- Weight

- 1.5 kg

- Mounting Type

- Panel Mount / Din Rail

- Feedback Type

- Incremental/Absolute Encoder

- Isolation

- Optical Isolation on Signal Ports

- Compatibility

- Compatible with PLC and Motion Controllers

- Protection Grade

- IP20

- Response Time

- 2 ms

- Startup Delay

- Programmable

- Supported Motor Type

- AC Servo Motor

- Communication Interface

- RS232/RS485/CANopen/EtherCAT

- Control Method

- Position, Speed and Torque Control

- Display Type

- LED Digital Display

- Humidity Range

- 10% - 90% RH (non-condensing)

- Maximum Altitude

- 2000 meters

About PAC SERVO DRIVE

Application & Usage Guidance for PAC SERVO DRIVE

Suitable for industrial automation, robotics, and CNC machinery, the PAC SERVO DRIVE provides exceptional control in manufacturing processes. To use, securely mount the unit using either the panel or DIN rail method. Connect compatible AC servo motors and integrate with PLCs or motion controllers via the extensive communication options. Adjust programmable startup delay and set desired parameters through the LED digital display. This drive ensures peerless response time, supported by advanced protection and isolation features for daily industrial tasks.

Packaging, Logistics & Sample Policy Information

PAC SERVO DRIVE units are packed with professional care to ensure safe arrival, wrapped in industrial-grade packaging materials. Our reliable logistics partners enable prompt delivery across the main domestic market at the lowest price. Upon request, sample units can be provided for evaluation prior to larger purchase commitments, supporting our transparent and customer-focused policy. Trust us to deliver both value and efficiency as a supplier and trader.

FAQs of PAC SERVO DRIVE:

Q: How does the PAC SERVO DRIVE ensure efficient and precise motion control?

A: The drive features advanced position, speed, and torque control methods, combined with high-efficiency (95%) operation, robust protection circuits, and programmable startup delay. Its compatibility with incremental or absolute encoders ensures realtime feedback for precise position control.Q: What types of motors and controllers can the PAC SERVO DRIVE interface with?

A: This servo drive is designed for AC servo motors and is fully compatible with PLCs and motion controllers. It offers versatile connectivity through RS232, RS485, CANopen, and EtherCAT interfaces.Q: Where can the PAC SERVO DRIVE be installed within an industrial environment?

A: The drive supports both panel mount and DIN rail installation, providing flexibility for various industrial automation setups, machinery cabinets, or robotics stations.Q: When is it necessary to consider the protection features of the PAC SERVO DRIVE?

A: Protection features such as over voltage, under voltage, overload, and over current are crucial during power fluctuations or demanding applications. These ensure safe and reliable operation at all times.Q: What is the process for adjusting the drives operational parameters?

A: Parameters can be conveniently set or adjusted via the LED digital display interface. Users can customize operation by configuring response time, startup delay, and desired analog or digital output characteristics.Q: How does the PAC SERVO DRIVE benefit industrial automation projects?

A: It offers excellent performance, a broad compatibility spectrum, rugged construction, and easy integration all contributing to reduced downtime, increased precision, and cost savings in automation projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PAC SERVO DRIVE Category

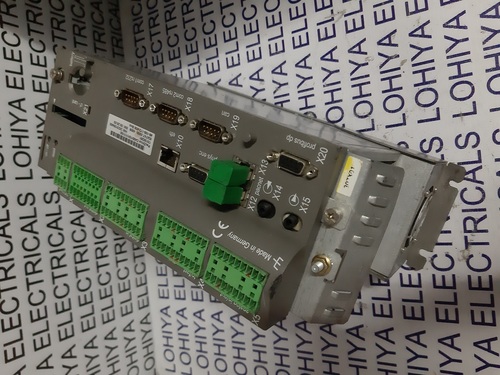

ELAU PAC SERVO DRIVE C400/10/1/1/1/00

Output Current : 10 A

Noise Level : <65 dB(A)

Voltage Protection : Integrated Overvoltage and Undervoltage Protection

Power Supply : 3phase 400 V AC

Current Range : 010 A

Storage Temperature : 25C to +70C

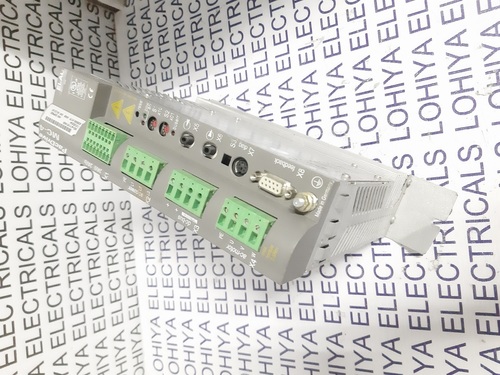

ELAU PAC SERVO DRIVE MC-4/11/01/400

Output Current : Up to 27 A

Noise Level : <65 dB

Voltage Protection : Overvoltage and Undervoltage Protection

Power Supply : 400 V AC, 50/60 Hz

Current Range : 027 A

Storage Temperature : 25C to +70C

PAC SERVO DRIVE

Output Current : 2A to 15A (Model Dependent)

Noise Level : <55dB

Voltage Protection : Overvoltage, Undervoltage, Short Circuit Protection

Power Supply : AC Input (220V/380V, 50/60Hz)

Current Range : 2A15A (Model Dependent)

Storage Temperature : 25C to +70C

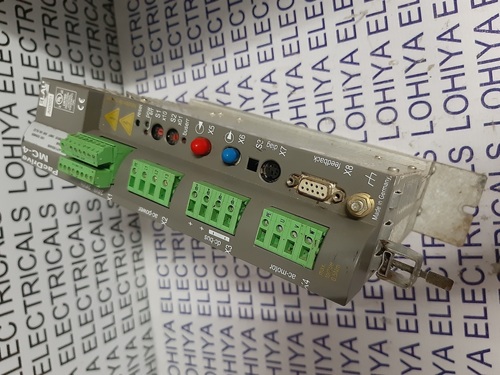

ELAU PAC SERVO DRIVE MC-4/11/03/400

Output Current : up to 11 A

Noise Level : < 65 dB

Voltage Protection : Integrated overvoltage and undervoltage protection

Power Supply : 3 x 400 V AC, 50/60 Hz

Current Range : up to 11 A

Storage Temperature : 25C to +70C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry