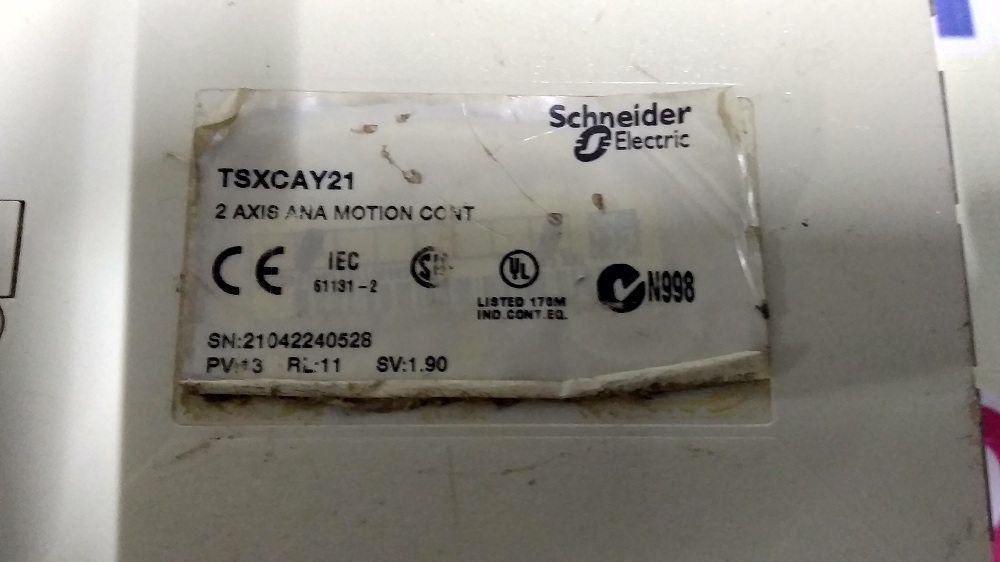

MOTION CONTROL MODULE

MOTION CONTROL MODULE Specification

- Output Type

- Digital Signal Output

- Working Temperature

- 0C to 60C

- Features

- Short Circuit Protection, High-Speed Processing

- Rated Current

- 1 A

- Cooling Method

- Passive Cooling

- Rated Power

- 24 W

- Power Supply

- External DC Adapter

- Connector Type

- Terminal Block Connector

- Output Current

- 1 A

- Noise Level

- <50 dB

- Operating Temperature

- 0C to 60C

- Power Factor

- 0.96

- Current Range

- 0.5 - 1.5 A

- Application

- CNC Machinery, Robotics, Automated Production Lines

- Phase

- Single Phase

- Product Type

- Motion Control Module

- Output Power

- 24 W

- Output Frequency

- 50/60 Hz

- Input Voltage

- 24 V DC

- Voltage Protection

- Overvoltage, Undervoltage

- Efficiency

- >90%

- Material

- Industrial Grade Plastic and Metal

- Line Regulation

- 0.5%

- Storage Temperature

- -40C to +85C

- Weight

- 320 g

- Dimensions

- 110 mm x 75 mm x 30 mm

- Control Interface

- RS-232/RS-485

- Isolation Voltage

- 1500 V AC

- Communication Protocols

- MODBUS, CANopen

- Firmware Upgrade

- Supported via Serial Interface

- Response Time

- <2 ms

- Display

- LED Status Indicators

- Protection Class

- IP20

- Mounting Type

- DIN Rail Mountable

- I/O Ports

- 4 Digital Inputs, 4 Digital Outputs

About MOTION CONTROL MODULE

Widely Used, Remarkable Advantages

The MOTION CONTROL MODULE is preferred by leading suppliers and traders for integration in CNC machinery, robotics, and automated production lines. Engineered for seamless control, it allows efficient motion regulation with high-speed digital outputs. Its user-friendly interface benefits operators by simplifying setup, while its reliability enhances productivity and reduces maintenance downtime. This immaculate unit is specially designed to meet the demanding needs of modern industrial automation.

Payment, Supply, and Packaging Highlights

Payment terms for the MOTION CONTROL MODULE are flexible, catering to business requirements for swift transactions. With a high supply rate, orders are promptly processed and professionally packaged to ensure immaculate product condition during delivery or drop-off. Each module is securely boxed for protection against transit damage, ensuring that your investment is delivered with complete reliability and peace of mind.

FAQs of MOTION CONTROL MODULE:

Q: How does the MOTION CONTROL MODULE integrate with existing automation systems?

A: The module connects seamlessly using RS-232/RS-485 interfaces and supports MODBUS and CANopen protocols, making integration with most industrial automation and CNC machinery straightforward.Q: What protective features does the control module offer during usage?

A: It is equipped with overvoltage and undervoltage protection, short circuit safeguards, and an IP20-rated enclosure, ensuring safe operation in demanding industrial environments.Q: Where can this module be installed for optimal efficiency?

A: It is DIN rail mountable and ideally placed in control cabinets within CNC machinery, robotics setups, or production line environments to maximize accessibility and performance.Q: When can users expect firmware updates, and how are they processed?

A: Firmware updates are supported via the serial interface, allowing routine enhancements and maintenance to be performed promptly whenever newer firmware is released.Q: What are the primary advantages of using this module in automation?

A: Operators benefit from high response speed, reliable power regulation, digital signal outputs, passive cooling, and minimal noise, resulting in improved system efficiency and reduced operational downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCHNEIDER Used PLC HMI AC DRIVE Category

MODICON QUATUM

Storage Temperature : 40C to +85C

Working Temperature : 0C to 60C

Features : Hot standby CPU, modular design, remote I/O, redundant power supply, extensive communication ports

Cooling Method : Natural convection

Weight : Approx. 1.5 kg (main CPU module)

Power Supply : 100240V AC (main unit), 24V DC (I/O modules)

SCHNEIDER HMI XBTGT1130

Storage Temperature : 20C to 60C

Working Temperature : 0C to 50C

Features : Touchscreen userfriendly interface programmable functionality

Cooling Method : Natural cooling

Weight : Approximately 0.5 kg

Power Supply : External DC power supply

SCHNEIDER HMI XBT RT500

Storage Temperature : 20C to +60C

Working Temperature : 0C to +50C

Features : Touchscreen Interface, Programmable, Multiple Communication Ports, LED Backlight, High Resolution

Cooling Method : Natural air cooling / Fanless

Weight : Approximately 1.2 kg

Power Supply : 24 V DC

schneider xbtot2110 HMI

Storage Temperature : 20 to +60 C

Working Temperature : 0 to 50 C

Features : Touchscreen interface, robust design, TFT LCD display, programmable function keys

Cooling Method : Natural convection

Weight : Approx. 0.63 kg

Power Supply : 24 V DC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry