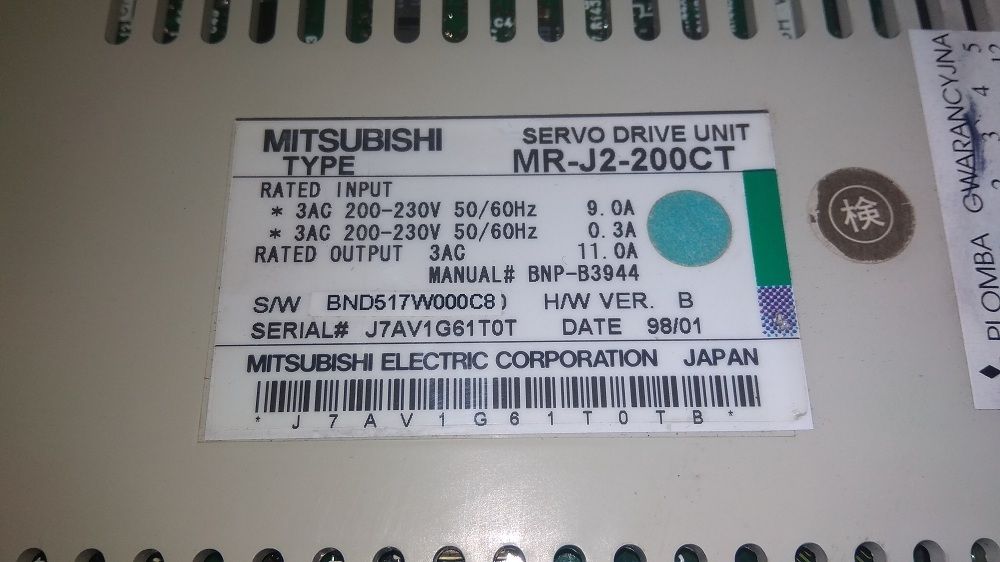

MITSUBISHI SERVO DRIVE

MITSUBISHI SERVO DRIVE Specification

- Surface Finish

- Matt

- Feature

- High Speed, Precision Control, Compact

- Humidity %

- Below 90% RH (Non-Condensing)

- Power Factor

- 0.98

- Mounting Type

- Panel Mount

- Insulation Material

- Thermoplastic

- Overheating Protection

- YES

- Operating Temperature

- 0C to 55C

- IP Rating

- IP20

- Shape

- Rectangular

- Efficiency

- >90%

- Connector Type

- Screw Terminal

- Product Type

- Servo Drive

- Application

- Industrial Automation & CNC Machinery

- Protection Level

- Overcurrent, Overvoltage, Overload

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 200-240 V AC

- Energy Consumption

- Low

- Output Type

- Digital & Analog

- Color

- Black

- Dimension (L*W*H)

- 165 x 80 x 140 mm

- Weight

- 1.5 kg

- Size

- Standard

- Phase

- Three Phase

- Input Voltage

- 200-240 V AC

- Material

- ABS Plastic & Metal

- Connection Type

- Terminal/Plug-in

About MITSUBISHI SERVO DRIVE

Applications and Users in Industrial Environments

The MITSUBISHI SERVO DRIVE is tailored for commercial uses, excelling in industrial automation and CNC machinery where precision and reliability are paramount. Engineers and technicians apply this drive through panel mounting, leveraging its cutting-edge vector, speed, and position control. Its versatility allows integration into both new builds and retrofitted systems. Renowned manufacturers and skilled tradespeople prefer this drive for its precision, user-friendly software, and robust protection features, making it an industry staple worldwide.

Domestic Market Advantage & Delivery Assurances

Focused on the main domestic markets, MITSUBISHI SERVO DRIVE is shipped swiftly with secure shipping, meticulous packing, and rapid dispatch. Delivery times are minimized to ensure minimal downtime for your operations. Each drive is packed to withstand transit challenges, guaranteeing its pristine arrival. The supplier offers a transparent sample policy, building customer confidence before bulk orders. Reliable after-sales support accompanies every dispatched unit, solidifying MITSUBISHIs reputation for excellence and customer-centric service.

FAQs of MITSUBISHI SERVO DRIVE:

Q: How can I integrate the MR-J2S-200A Servo Drive into my existing automation systems?

A: The MR-J2S-200A can be integrated using its terminal/plug-in connection with three-phase electrical setups. Its compatibility with MELSOFT MR Configurator software allows seamless configuration and communication through RS-422/RS-232C interfaces.Q: What benefits does customizable control provide for industrial applications?

A: Customizable vector, speed, and position control methods offer superior flexibility, precision, and tailored performance for diverse machinery requirements, enhancing productivity and energy efficiency for industrial users.Q: When is dynamic braking engaged and how does it help in operations?

A: Dynamic braking activates during rapid stops or emergencies, dissipating excess kinetic energy to prevent damage. This function ensures both safety and longevity for connected motors, especially in high-speed or high-torque operations.Q: Where is the MR-J2S-200A most commonly deployed?

A: This servo drive is most commonly used in industrial automation and CNC machinery, particularly in manufacturing plants, robotics applications, and motion control systems requiring precise feedback and stable operation.Q: What is the recommended environment for optimal MR-J2S-200A performance?

A: Optimal performance is achieved in environments with temperatures between 0C and 55C and humidity below 90% RH (non-condensing). Proper coolingeither self-cooled or with an external fanis also essential for high-speed, precise operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MITSUBISHI Used PLC SERVO DRIVE Category

MITSUBISHI SERVO DRIVE

Surface Finish : Powder Coated

Material : Industrial Grade ABS & Metal

Connection Type : Screw Terminal

Application : Industrial Automation; CNC Machinery; Robotics

Feature : High Precision, Fast Response, Easy Parameter Setting

Product Type : Servo Drive

MITSUBISHI MELSEC POWER SUPPLY A1S61PN

Surface Finish : Matte

Material : Metal and plastic composite

Connection Type : Plugin connections

Application : Industrial automation systems

Feature : Compact design Reliable performance

Product Type : Power supply unit

Mitsubishi Programmable Controller FXON-24MR-ES

Surface Finish : Smooth

Material : Plastic

Connection Type : Wired

Application : Industrial Automation

Feature : Integrated I/O and CPU

Product Type : Programmable Controller

MITSUBISHI MELSEC CPU AJ72T25B

Surface Finish : Matte

Material : Plastic

Connection Type : Wired

Application : Industrial Automation

Feature : Programmable Controller

Product Type : CPU Module

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry