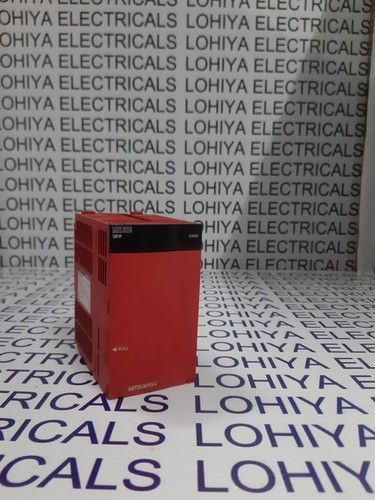

MITSUBISHI ELECTRIC AC SERVO MOTOR

MITSUBISHI ELECTRIC AC SERVO MOTOR Specification

- Rated Current

- 4.8 A

- Rated Power

- 750 W

- Connector Type

- Circular multi-pin connector

- Operating Temperature

- 0C to +40C

- Features

- Compact design, high precision, programmable

- Power Factor

- >0.95

- Working Temperature

- 0C to +40C

- Output Type

- Rotational

- Phase

- Three Phase

- Power Supply

- AC power

- Noise Level

- Low noise operation

- Output Current

- 4.8 A

- Application

- Industrial automation, robotics, CNC machinery

- Cooling Method

- Natural cooling

- Current Range

- 0-5 A

- Product Type

- AC Servo Motor

- Output Power

- 750 W

- Output Frequency

- 50/60 Hz

- Input Voltage

- 200-240 V AC

- Voltage Protection

- Over-voltage, under-voltage protection

- Efficiency

- High efficiency

- Material

- Aluminum housing

- Line Regulation

- 1%

- Storage Temperature

- -20C to +60C

- Weight

- 2.8 kg

About MITSUBISHI ELECTRIC AC SERVO MOTOR

Outstanding Applications & Advanced Features

The MITSUBISHI ELECTRIC AC SERVO MOTOR HC-KFS73 is widely used in industrial automation, robotics, and CNC machinery. Its compact design, resplendent aluminum housing, and natural cooling method assure consistent performance in environments from 0C to +40C. High precision, programmable capabilities, and direct start operation enhance usage flexibility, making it ideal for precise motion control tasks where reliability and efficiency are paramount.

Payment Terms, Certifications & Packaging Details

Highly competitive expenditure and lowest price offers are available for this laureate motor. Payment terms include multiple options for smooth transactions. Certified with CE marking, the motor meets stringent safety and quality standards. For Goods Transport, each unit is securely packed to ensure safe delivery across India, adhering to industry protocols and minimizing damage during transit.

FAQs of MITSUBISHI ELECTRIC AC SERVO MOTOR:

Q: How does the MITSUBISHI ELECTRIC AC SERVO MOTOR HC-KFS73 enhance industrial automation?

A: With high precision, low noise operation, and programmable features, this motor optimizes motion control and increases overall efficiency in industrial automation processes.Q: What makes the HC-KFS73 model suitable for CNC machinery and robotics?

A: The servo motors incremental encoder, robust torque range, and high efficiency make it ideal for applications requiring accurate positioning and consistent performance in CNC machinery and robotics.Q: Where is the best site to install this AC Servo Motor?

A: It is best installed in clean, controlled environments such as manufacturing lines, robotics workstations, and automated CNC setups within the permissible temperature and humidity range.Q: What certifications does this motor have for quality assurance?

A: The motor features CE Certification, confirming compliance with international safety and quality standards for industrial equipment.Q: How is the motor packaged and transported to ensure its safety?

A: Goods are securely packed in robust, industry-standard packaging to avoid transit damage, ensuring safe arrival at your location anywhere in India.Q: When is the optimal time for maintenance to guarantee longevity?

A: Scheduled maintenance every 5,000 operating hours is recommended to achieve its full life expectancy of up to 20,000 operating hours.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MITSUBISHI POWER SUPPLY Category

Mitsubishi Power Supply Unit Q61p-a2

Operating Temperature : 0C to 55C

Features : Compact Design, Easy Installation, High Reliability

Storage Temperature : 25C to 75C

Product Type : Power Supply Unit

Connector Type : Screw Terminal

Working Temperature : 0C to 55C

Mitsubishi Electric Power Supply

Operating Temperature : 10C to +60C

Features : Compact Size, High Reliability, LED Status Indicator

Storage Temperature : 25C to +85C

Product Type : Switching Mode Power Supply

Connector Type : Screw Terminal

Working Temperature : 10C to +60C

MITSUBISHI POWER SUPPLY

Operating Temperature : 10 to +60C

Features : Short Circuit Protection, Overload Protection, LED Indicator

Storage Temperature : 25 to +75C

Product Type : MITSUBISHI Power Supply

Connector Type : Screw Terminal

Working Temperature : 10 to +60C

MITSUBISHI POWER SPPLY

Operating Temperature : 10C to +60C

Features : Compact Design, Reliable Performance, Safety Certified

Storage Temperature : 20C to +85C

Product Type : Power Supply Unit

Connector Type : Screw Terminal

Working Temperature : 10C to +60C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry