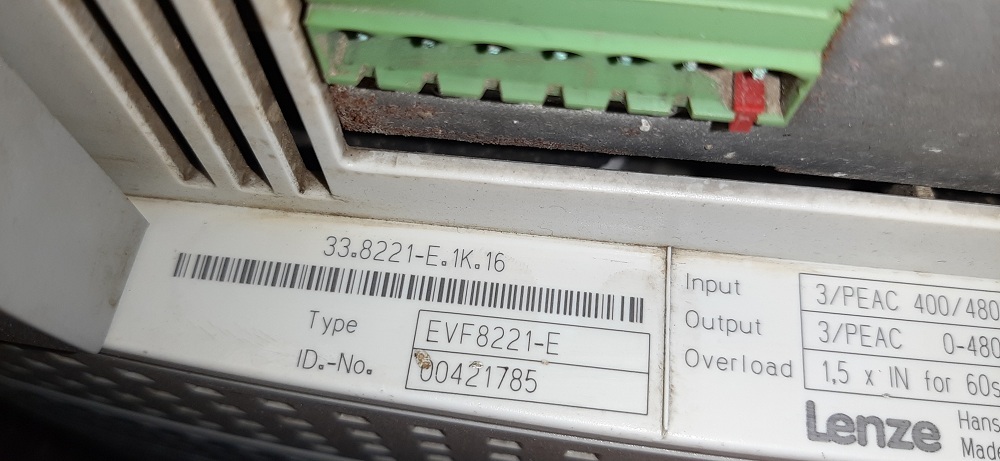

LENZE SERVO DRIVE EVF8221-E

LENZE SERVO DRIVE EVF8221-E Specification

- Rated Current

- 5.5 A

- Current Range

- 0-6 A

- Noise Level

- <65 dB

- Features

- Compact Design, High Dynamic Performance, Easy Operation

- Phase

- Single/Three Phase

- Rated Power

- 1.1 kW

- Output Type

- Analog/Digital

- Operating Temperature

- 0C to 50C

- Output Current

- 5.5 A

- Connector Type

- Screw Terminal

- Working Temperature

- 0C to 50C

- Power Factor

- >0.95

- Application

- Industrial Automation, Robotics, Packaging, CNC Machines

- Power Supply

- AC Power Supply

- Cooling Method

- Forced Air Cooling

- Product Type

- Servo Drive

- Output Power

- 1.1 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 230V AC single-phase/three-phase

- Voltage Protection

- Overvoltage, Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- Industrial Grade ABS/Metal

- Line Regulation

- < 0.5%

- Storage Temperature

- -25C to +55C

- Weight

- Approx. 1.5 kg

About LENZE SERVO DRIVE EVF8221-E

Industrial Versatility & Competitive Edge

The LENZE SERVO DRIVE EVF8221-E showcases exceptional commercial adaptability. Its top performance in robotics, packaging, CNC machines, and industrial automation ensures businesses remain ahead. The units ravishing compact design, meritorious high dynamic performance, and easy operation provide a competitive advantage. Advanced protection and efficiency further secure reliable operation in demanding environments, making it suitable for a wide range of manufacturing and automation applications.

Supply Commitment & Market Reach

With a substantial proposal amount and efficient delivery schedule, the LENZE SERVO DRIVE EVF8221-E is regularly delivered across the main domestic and export markets. Competitive sale price and reliable supply ability ensure customer satisfaction. Its robust presence is realized in key industrial regions, making it a sought-after choice for traders and suppliers intent on maintaining high operational standards and broad market access worldwide.

FAQs of LENZE SERVO DRIVE EVF8221-E:

Q: How does the LENZE SERVO DRIVE EVF8221-E ensure efficient and reliable operation in industrial settings?

A: It utilizes vector control and V/f control methods, with built-in voltage protection and a high efficiency of up to 98%. Advanced features such as an industrial-grade ABS/metal casing and forced air cooling guarantee reliable performance even in demanding environments.Q: What commercial uses is the LENZE SERVO DRIVE EVF8221-E ideal for?

A: This drive is perfectly suited for industrial automation, robotics, packaging machinery, and CNC machines, providing precision control and high dynamic performance for complex motion tasks.Q: Where can the LENZE SERVO DRIVE EVF8221-E be mounted and what environments is it suitable for?

A: Designed for panel mounting, it can be installed in control cabinets and operates effectively within ambient humidity of 5% to 95%, and temperatures between 0C to 50C, ensuring flexibility for diverse industrial environments.Q: When is it beneficial to use the built-in braking chopper feature?

A: The built-in braking chopper is beneficial when rapid deceleration or stopping is required, especially in applications involving frequent start-stop cycles such as robotics or fast-paced packaging lines.Q: What adjustable parameters can users set on the LENZE SERVO DRIVE EVF8221-E?

A: Users can configure acceleration and deceleration times, torque settings, speed limits, and output frequency between 0-400 Hz, allowing precise customization for each applications needs.Q: How is the LENZE SERVO DRIVE EVF8221-E delivered and what is its sale price policy?

A: It is delivered with reliable scheduling, and sale price is determined competitively based on proposal amount and current market conditions, facilitating cost-effective procurement for customers worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE EVF9324-EVV004

Rated Current : 11.0 A

Current Range : 011.0 A

Input Voltage : 3 x 400 V AC (10%)

Noise Level : <65 dB(A)

Features : Compact Design, Integrated Brake Chopper, Flexible Communication Interfaces, Userfriendly Operation, High Dynamic Response

Voltage Protection : Overvoltage/Undervoltage Protection Included

LENZE SERVO DRIVE EVF9326-EV

Rated Current : 25.7 A

Current Range : 026 A

Input Voltage : 3 x 400 V AC (15 % / +10 %)

Noise Level : <65 dB

Features : Dynamic braking, Short circuit protection, Overload protection, Userfriendly interface, Programmable functions

Voltage Protection : Integrated overvoltage and undervoltage protection

LENZE EVF9324 EV DRIVE

Rated Current : 45 A

Current Range : 0 45 A

Input Voltage : 400 V AC (3phase)

Noise Level : <70 dB(A)

Features : Integrated brake chopper, programmable parameters, LCD display

Voltage Protection : Overvoltage and undervoltage protection integrated

LENZE-Evf8216-e

Rated Current : 16A

Current Range : 16A

Input Voltage : 230V AC

Noise Level : Low

Features : Compact Design Easy Integration

Voltage Protection : Overvoltage Undervoltage

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry