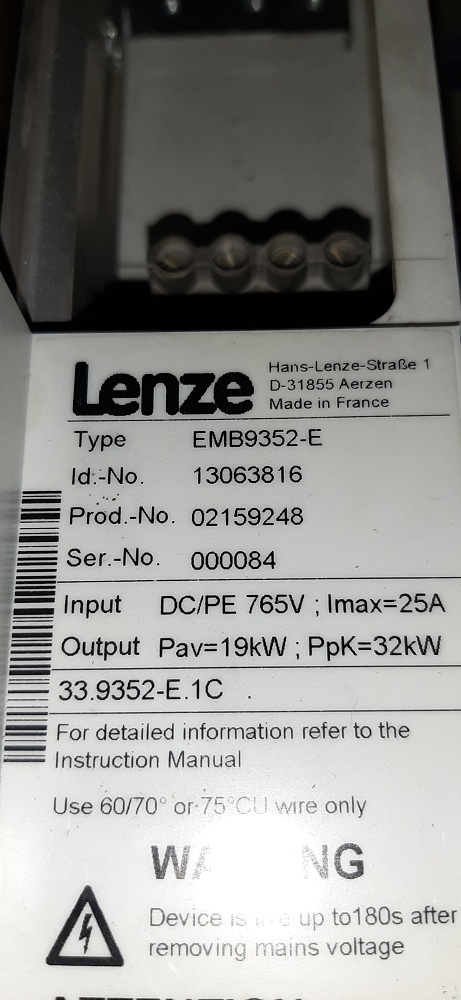

LENZE SERVO DRIVE EMB9352-E

LENZE SERVO DRIVE EMB9352-E Specification

- Output Current

- 12.5 A

- Connector Type

- Screw Terminal

- Working Temperature

- 0C to +45C

- Current Range

- 0 13 A

- Operating Temperature

- 0C to +45C

- Rated Power

- 5 kW

- Power Supply

- AC Mains

- Rated Current

- 12.5 A

- Noise Level

- <65 dB

- Output Type

- Three Phase

- Phase

- 3 Phase

- Power Factor

- >0.95

- Cooling Method

- Forced Air Cooling

- Application

- Industrial Automation, CNC Machines, Packaging Machines, Robotics

- Features

- Compact Design, Programmable, Diagnostic LED Indicators, Short Circuit Protection, Safe Torque Off (STO)

- Product Type

- Servo Drive

- Output Power

- 5 kW

- Output Frequency

- 0-500 Hz

- Input Voltage

- 3 x 400 V AC

- Voltage Protection

- Integrated Over-voltage and Under-voltage Protection

- Efficiency

- >96%

- Material

- Industrial Grade Plastic & Metal

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- 3.8 kg

- Mounting Type

- Panel Mounted

- Communication Interfaces

- CANopen, RS485

- Programming Function

- Parameter Setting via Keypad or PC Tool

- Overload Capability

- 150% of Rated Current for 60 seconds

- Dimensions (W x H x D)

- 168 mm x 281 mm x 175 mm

- Cooling Fan

- Integrated

- Frequency Resolution

- 0.01 Hz

- Motor Type Supported

- Synchronous and Asynchronous Servo Motors

- Humidity

- Max 95% (non-condensing)

- Start-up Torque

- 200% at 0.5 Hz

- Protection Class

- IP20

- Model

- EMB9352-E

- Brake Control

- Integrated Brake Chopper

- Display

- Built-in Digital Display

- Control Method

- Vector Control and V/f Control

About LENZE SERVO DRIVE EMB9352-E

Step into the elite spotlight with the LENZE SERVO DRIVE EMB9352-Ea celebrated solution in industrial automation. Offering vector and V/f control methods, it empowers operators with breathtaking precision and illustrious flexibility. Its built-in digital display and integrated brake chopper promote seamless operation and system protection. With CANopen and RS485 interfaces for connectivity, this panel-mounted, IP20-class drive supports both synchronous and asynchronous servo motors. The EMB9352-E stands out for its compact design, programmable features, and unparalleled reliability, making it a top choice for CNC machines, robotics, and packaging environments.

Competitive Advantages and Versatile Usage

The LENZE SERVO DRIVE EMB9352-E brings competitive advantages like high overload capacity (150% rated current for 60 seconds) and a remarkable start-up torque (200% at 0.5 Hz), making it suitable for demanding applications. Widely used by automation professionals, it is celebrated as a reliable powertrain in CNC machines, packaging systems, and robotic setups. Its compact form, programmability, and diagnostic LED indicators ensure elite performance and seamless monitoring across diverse industrial environments.

Delivery Time, Domestic Market, and Sample Policy

LENZE SERVO DRIVE EMB9352-E is meticulously handed over to clients with swift delivery times, ensuring minimal project delays. Transportation and freight solutions cater primarily to the main domestic industrial market, making distribution efficient and reliable. Sample policies are tailored for direct engagement with industrial partners, offering evaluation units for on-site testing. This commitment elevates user confidence, ensuring every drive delivered exceeds expectations.

Competitive Advantages and Versatile Usage

The LENZE SERVO DRIVE EMB9352-E brings competitive advantages like high overload capacity (150% rated current for 60 seconds) and a remarkable start-up torque (200% at 0.5 Hz), making it suitable for demanding applications. Widely used by automation professionals, it is celebrated as a reliable powertrain in CNC machines, packaging systems, and robotic setups. Its compact form, programmability, and diagnostic LED indicators ensure elite performance and seamless monitoring across diverse industrial environments.

Delivery Time, Domestic Market, and Sample Policy

LENZE SERVO DRIVE EMB9352-E is meticulously handed over to clients with swift delivery times, ensuring minimal project delays. Transportation and freight solutions cater primarily to the main domestic industrial market, making distribution efficient and reliable. Sample policies are tailored for direct engagement with industrial partners, offering evaluation units for on-site testing. This commitment elevates user confidence, ensuring every drive delivered exceeds expectations.

FAQs of LENZE SERVO DRIVE EMB9352-E:

Q: How does the LENZE SERVO DRIVE EMB9352-E ensure precise motor control during operation?

A: The EMB9352-E utilizes advanced vector control and V/f control methods, providing precise regulation of synchronous and asynchronous servo motors. This ensures optimal speed, torque, and efficiency across varying load conditions.Q: What are the key benefits of the built-in digital display and integrated brake chopper?

A: The built-in digital display allows for real-time monitoring of operational parameters, simplifying adjustments and diagnostics. The integrated brake chopper efficiently manages stopping and braking, enhancing safety and reliability.Q: Where can the LENZE SERVO DRIVE EMB9352-E be installed for industrial use?

A: Designed for panel mounting, the EMB9352-E fits seamlessly into control cabinets used in industrial automation, CNC machines, robotics, and packaging machines.Q: When is the best time to consider using the EMB9352-E drive in your automation projects?

A: It is ideal to use the EMB9352-E when high efficiency, overload capability, and compact design are required. It performs exceptionally in applications demanding robust servo control and advanced protective features.Q: What is the process of programming the LENZE SERVO DRIVE EMB9352-E?

A: Programming the EMB9352-E is straightforward; users can set parameters via the integrated keypad or through a PC tool, granting flexibility for tailored control logic and system integration.Q: How does the drives protection features benefit operational safety and longevity?

A: The EMB9352-E boasts integrated over-voltage, under-voltage protection, Safe Torque Off (STO), and short circuit protection, collectively promoting safe operation, equipment longevity, and reduced downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE EVS9324-ES

Line Regulation : <1%

Efficiency : up to 97%

Operating Temperature : 0C to +55C

Current Range : 013 A

Output Frequency : 0599 Hz

Working Temperature : 0C to +55C

LENZE SERVO DRIVE EVF8213-E

Line Regulation : 0.5%

Efficiency : 95%

Operating Temperature : 0C to +55C

Current Range : 04.5 A

Output Frequency : 0400 Hz

Working Temperature : 0C to +55C

LENZE ESMD371X2SFA DRIVE

Line Regulation : 0.1%

Efficiency : Up to 98%

Operating Temperature : 10C to +45C

Current Range : 0.5 to 2.3 A

Output Frequency : 0 650 Hz

Working Temperature : 10C to +45C

LENZE EVF8202 E DRIVE

Line Regulation : 1%

Efficiency : Up to 98%

Operating Temperature : 10C to +55C

Current Range : 0.7 A 1.5 A

Output Frequency : 0480 Hz

Working Temperature : 10C to +55C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry