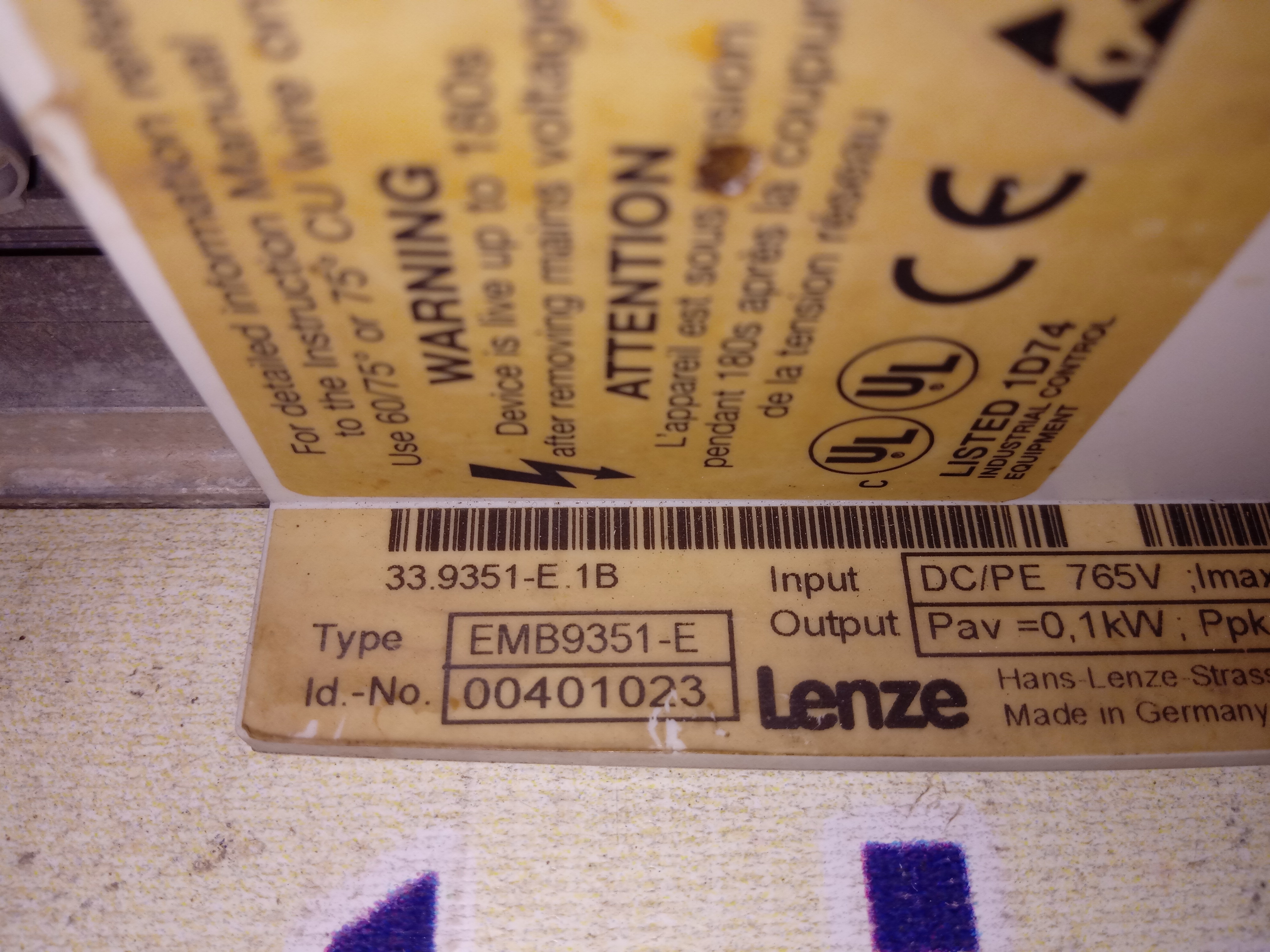

LENZE SERVO DRIVE EMB9351-E

LENZE SERVO DRIVE EMB9351-E Specification

- Output Current

- 5.5 A

- Application

- Industrial automation, CNC machinery, Packaging machines

- Noise Level

- <60 dB

- Power Factor

- >0.95

- Output Type

- Analog / Digital

- Cooling Method

- Integrated forced air cooling

- Power Supply

- AC Supply

- Phase

- Three Phase

- Working Temperature

- 0C to +55C

- Rated Current

- 5.5 A

- Connector Type

- Screw terminal

- Features

- Compact design, high dynamic performance, integrated safety functions, easy commissioning

- Current Range

- 0-6 A

- Operating Temperature

- 0C to +55C

- Rated Power

- 2.2 kW

- Product Type

- Servo Drive

- Output Power

- 2.2 kW

- Output Frequency

- 0-500 Hz

- Input Voltage

- 3 x 400 V AC

- Voltage Protection

- Overvoltage and undervoltage protection

- Efficiency

- Up to 98%

- Material

- Industrial grade components with metal housing

- Line Regulation

- 0.2%

- Storage Temperature

- -25C to +70C

- Weight

- 3.1 kg

- Safety Functions

- STO (Safe Torque Off)

- Display

- LED status and parameter display

- IP Protection Class

- IP20

- Braking Unit

- Integrated dynamic braking

- Mounting Method

- Panel mounting

- Communication Interfaces

- CANopen, EtherCAT, PROFIBUS (optional)

- Motor Types Supported

- Synchronous and asynchronous motors

- Digital Inputs/Outputs

- 6 DI / 2 DO

- Analog Inputs/Outputs

- 2 AI / 1 AO

- EMC Compliance

- EN 61800-3

- Control Method

- Field-oriented vector control (FOC)

About LENZE SERVO DRIVE EMB9351-E

LENZE SERVO DRIVE EMB9351-E: Optimum Use & Advantages

Ideal for CNC machinery, industrial automation, and packaging equipment, the LENZE SERVO DRIVE EMB9351-E stands out as one of the finest choices for commercial applications. Its high dynamic performance, robust safety functions, and easy commissioning make it perfect for demanding environments. Users benefit from enhanced precision, reduced noise levels, and an operational range that meets diverse industry standards. This acclaimed servo drive is the go-to solution for those seeking dependable control and efficiency in complex systems.

Order Processing & Domestic Delivery Information

The LENZE SERVO DRIVE EMB9351-E is readily available across the main domestic market, ensuring swift order processing and reliable transportation. Orders are handled promptly, with a proposal amount tailored to your specific requirements. Delivery timeframes are optimized for efficiency, ensuring fast arrival. For peace of mind, samples can be requested to evaluate product compatibility before committing to large-scale orders. This seamless sales process reflects our commitment to providing top-tier industrial solutions and customer satisfaction.

FAQs of LENZE SERVO DRIVE EMB9351-E:

Q: How does the LENZE SERVO DRIVE EMB9351-E enhance industrial automation processes?

A: The drive delivers advanced field-oriented vector control (FOC) and supports both synchronous and asynchronous motors, providing high dynamic performance and precise control, which are essential for industrial automation applications.Q: What types of motors are compatible with the LENZE SERVO DRIVE EMB9351-E?

A: This servo drive supports both synchronous and asynchronous motors, increasing its versatility across various machine applications.Q: When should I use the integrated safety functions of the LENZE SERVO DRIVE EMB9351-E?

A: Use the integrated STO (Safe Torque Off) safety function whenever operational safety is paramount, such as during maintenance or emergency stops, ensuring secure and reliable shutdowns.Q: Where can the LENZE SERVO DRIVE EMB9351-E be installed?

A: It is designed for panel mounting within industrial machinery such as CNC machines, packaging equipment, and automated production lines, making it adaptable for various commercial environments.Q: What is the process for commissioning the LENZE SERVO DRIVE EMB9351-E?

A: Commissioning is straightforward owing to its intuitive LED parameter display and user-friendly interface, simplifying setup and reducing installation time.Q: What are the main benefits of selecting the LENZE SERVO DRIVE EMB9351-E?

A: Key benefits include high efficiency (up to 98%), robust protection features, integrated safety, compact design, and compatibility with leading communication protocols, making it a spectacular option for industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE E82EV751K2C

Material : Industrial Grade Plastic and Metal

Application : Automation, Packaging, CNC Machines, Conveyor Systems

Input Voltage : 200240 VAC

Storage Temperature : 25C to +70C

Voltage Protection : Over/Under Voltage Protection

Output Power : 0.75 kW

LENZE E82EV152 2C000 DRIVE

Material : Industrialgrade plastic housing with heat sinks

Application : Industrial automation, conveyors, pumps, fans, and machine tools

Input Voltage : 3phase 400 V AC

Storage Temperature : 25C to +70C

Voltage Protection : Integrated overvoltage and undervoltage protection

Output Power : 1.5 kW

LENZE AC SERVO DRIVE

Material : Industrial Grade Plastic & Metal Body

Application : Industrial Automation, Robotics, CNC Machines, Packaging, Printing

Input Voltage : 230V/400V AC, 50/60 Hz (single or three phase depending on model)

Storage Temperature : 25C to +70C

Voltage Protection : Under/Over voltage protection builtin

Output Power : 0.4 kW to 15 kW (range based on model)

KUKA E93DA113I4B531

Material : Metal

Application : Industrial automation

Input Voltage : 220V AC

Storage Temperature : 20C to 70C

Voltage Protection : Overvoltage protection

Output Power : 1kW

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry