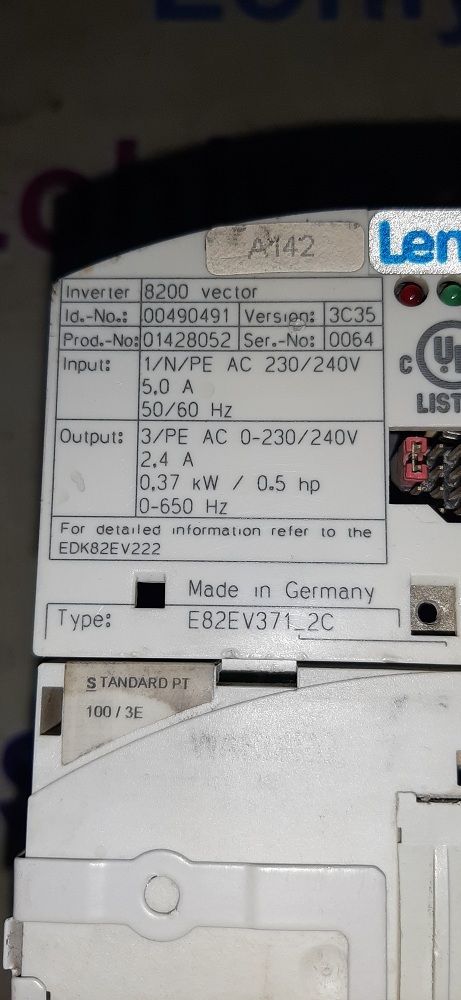

LENZE SERVO DRIVE E82EV371_2C

LENZE SERVO DRIVE E82EV371_2C Specification

- Power Factor

- >= 0.95

- Output Type

- Three Phase

- Connector Type

- Plug-in Removable Terminal Block

- Output Current

- 2.3 A

- Power Supply

- AC Power Supply

- Rated Current

- 2.3 A

- Rated Power

- 0.37 kW

- Working Temperature

- -10C to +55C

- Application

- Automation, Conveyor Systems, Packaging Machines, Robotics

- Current Range

- Up to 2.3 A

- Phase

- Single / Three Phase

- Operating Temperature

- -10C to +55C

- Noise Level

- Low Noise Operation

- Cooling Method

- Fan Cooling

- Features

- Integrated Brake Control, Integrated Communication Interfaces, Easy to Install

- Product Type

- Lenze Servo Drive

- Output Power

- 0.37 kW

- Output Frequency

- 0-599 Hz

- Input Voltage

- 200-240V AC

- Voltage Protection

- Overvoltage/Undervoltage Protection

- Efficiency

- High Efficiency

- Material

- Industrial Grade Components

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 1.7 kg

- Control Method

- V/f Control, Vector Control

- Protection Class

- IP20

- Communication Interface

- CANopen, RS485 (integrated)

- Dimensions (H x W x D)

- 173 mm x 74 mm x 143 mm

- Braking Unit

- Integrated Braking Chopper

- Mounting Type

- Panel Mount

- Display

- LED Status Display

- Service Life

- > 10 years (under standard conditions)

- Model Number

- E82EV371_2C

About LENZE SERVO DRIVE E82EV371_2C

Cutting-Edge Features & Diverse Applications

The LENZE SERVO DRIVE E82EV371_2C stands out for its flawless performance and advanced features, making it a staple in automated machinery. Integrated brake control, multiple communication options, and easy panel mounting empower engineers in sectors such as robotics, conveyor systems, and packaging machines. Its robust output and versatile control methods elevate system efficiency, while low-noise operation and sturdy industrial-grade components ensure reliability in challenging application media environments.

Sample Policies & Exchange Details

Interested clients can request samples of the LENZE SERVO DRIVE E82EV371_2C. The sample is securely packaged and handed over at the designated FOB port. Our sample policy encourages equitable exchange opportunities, ensuring you can test the drives performance before making a bulk purchase decision. Professional handling and swift delivery facilitate a seamless experience, letting you evaluate product quality and operational compatibility in your working environment.

FAQs of LENZE SERVO DRIVE E82EV371_2C:

Q: How do I install the LENZE SERVO DRIVE E82EV371_2C on an automation system?

A: The LENZE SERVO DRIVE E82EV371_2C is designed for panel mounting and features plug-in removable terminal blocks. Integrated communication interfaces like CANopen and RS485 make installation straightforward for engineers and technicians across automation setups.Q: What protection features does the E82EV371_2C servo drive offer?

A: It provides IP20-rated protection, overvoltage and undervoltage safeguards, and a service life surpassing 10 years under standard conditions, ensuring reliable operation in industrial environments.Q: Where is the sample of LENZE SERVO DRIVE E82EV371_2C handed over?

A: Samples are securely packaged and exchanged at the specified FOB port, as per our standard sample policy.Q: What are the main application areas for the LENZE SERVO DRIVE E82EV371_2C?

A: The servo drive is ideal for use in automation, conveyor systems, packaging machines, and robotics, where stringent control and performance reliability are essential.Q: How does the integrated braking chopper benefit the system?

A: The built-in braking unit ensures smooth stopping and precise motion control, optimizing safety and overall operational performance in machinery.Q: What is the typical process for requesting a sample?

A: Clients can request a sample through the supplier or trader, after which the product is safely packaged and handed over for exchange at the designated FOB port.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE E84AVHCE3714SB0

Line Regulation : 0.5% max

Voltage Protection : Overvoltage and undervoltage protection

Input Voltage : 400 V AC

Output Current : 8.5 A

Power Supply : 3 x 400 V AC, 50/60 Hz

Rated Power : 3.7 kW

LENZE SERVO DRIVE EVF8244-E

Line Regulation : 1%

Voltage Protection : Overvoltage and Undervoltage Protection

Input Voltage : 3phase 400 V AC

Output Current : 11.0 A

Power Supply : 400 V AC, 3phase

Rated Power : 4 kW

LENZE SERVO DRIVE EVF8224-E

Line Regulation : 1%

Voltage Protection : Overvoltage and Undervoltage Protection

Input Voltage : 3 x 400 V AC (Threephase)

Output Current : 6 A

Power Supply : AC supplied

Rated Power : 2.4 kW

LENZE-Evf8214-e

Line Regulation : Not Available

Voltage Protection : Overvoltage Undervoltage

Input Voltage : 380480V AC

Output Current : 4.0A

Power Supply : AC

Rated Power : Not Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry