LENZE SERVO DRIVE E82EV251_2C

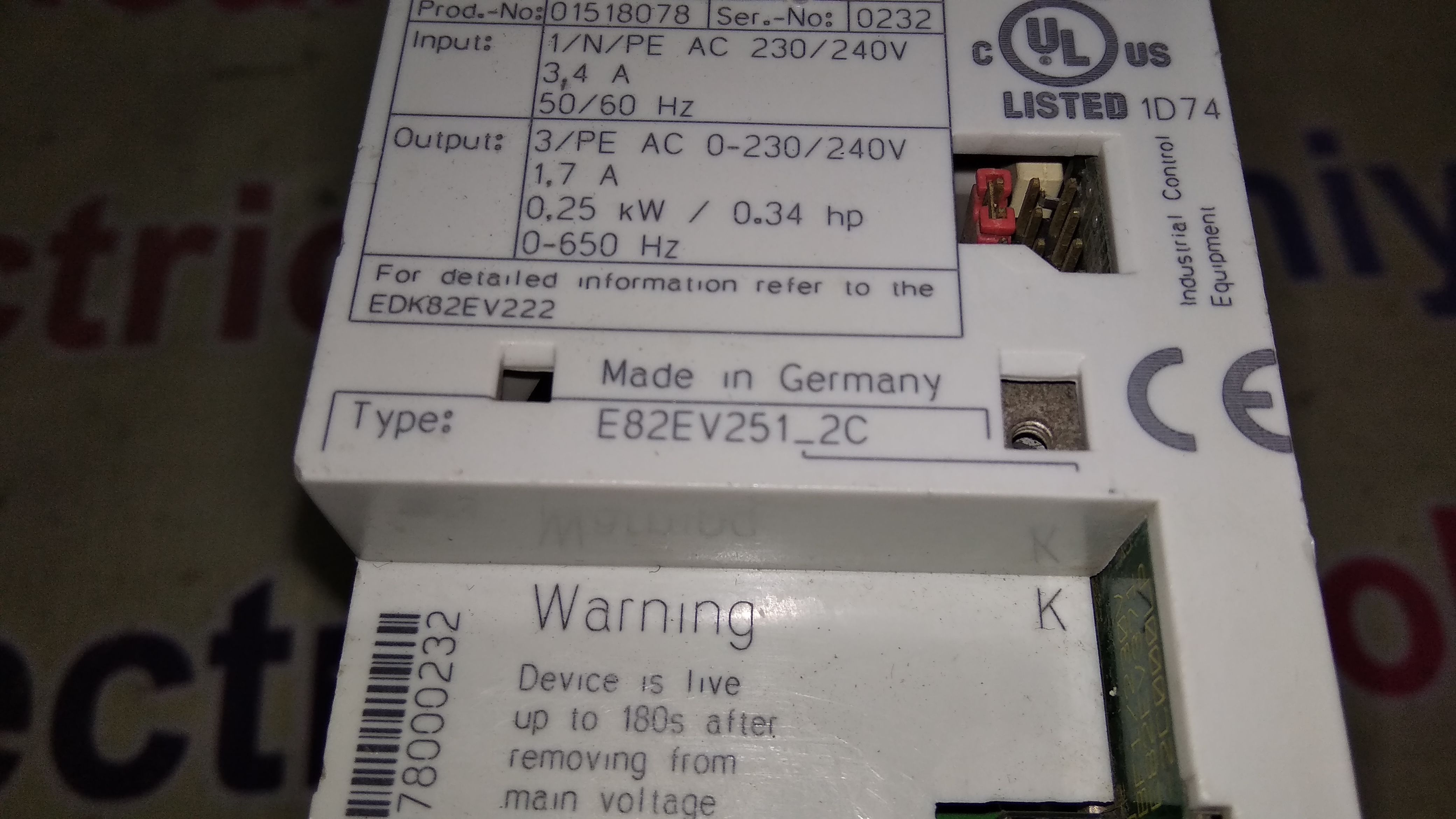

LENZE SERVO DRIVE E82EV251_2C Specification

- Noise Level

- <60 dB

- Rated Power

- 0.25 kW (1/3 HP)

- Application

- Industrial Automation, Packaging, Conveyors, Textile Machines

- Working Temperature

- -10C to +55C

- Power Supply

- 200-240V AC, 50/60 Hz

- Output Current

- 1.5 A

- Operating Temperature

- -10C to +55C

- Features

- Compact design, Easy parameterization, Integrated brake chopper, Diagnostics interface

- Connector Type

- Screw Terminal

- Cooling Method

- Fan cooled

- Phase

- Single Phase / Three Phase

- Power Factor

- >0.95

- Output Type

- Three-Phase

- Rated Current

- 1.5 A

- Current Range

- 0 to 2.5 A

- Product Type

- AC Servo Drive

- Output Power

- 0.25 kW

- Output Frequency

- 0 to 500 Hz

- Input Voltage

- 230 V AC

- Voltage Protection

- Overvoltage/Undervoltage Protection

- Efficiency

- >95%

- Material

- Industrial Grade Plastic and Metal

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 1.2 kg

- Enclosure Rating

- IP20

- Overload Capacity

- 200% for 3 seconds

- Relative Humidity

- 5% to 95% non-condensing

- Altitude

- Up to 1000 m without derating

- Display Type

- LED Status Display

- Start-Up/Commissioning

- Simple Plug and Play

- Mounting Type

- Panel Mount

- Brake Control

- Integrated Brake Chopper

- Control Type

- Vector and V/f Control

- Communication Interface

- RS485

- Firmware Upgrades

- Upgradeable via PC Software

- Motor Feedback

- Incremental Encoder Supported

About LENZE SERVO DRIVE E82EV251_2C

Advantages & Applications of LENZE SERVO DRIVE E82EV251_2C

Experience the advantage of easy parameterization and plug-and-play setup with the LENZE E82EV251_2C. This servo drive is engineered for seamless integration in both specific and general industrial uses, such as packaging lines, textile machines, and conveyors. Its compact design and high reliability enable swift panel mounting, while its efficient cooling system ensures stable operation. Whether used in standalone machinery or complex automation setups, this drive delivers exceptional precision and performance.

Sample Policy, Domestic & Export Market Presence

Our sample policy for the LENZE SERVO DRIVE E82EV251_2C enables evaluation via purchase orders, with shipment and delivery tracked for complete transparency. Samples are available to prospective buyers prior to large-scale procurement. The product is widely recognized in the main domestic market, while our export network spans key global regions. We ensure prompt shipment and reliable delivery for both domestic and international clients, making global sourcing seamless for industrial automation needs.

FAQs of LENZE SERVO DRIVE E82EV251_2C:

Q: How do I install the LENZE SERVO DRIVE E82EV251_2C?

A: The drive features a panel mount design with screw terminals, allowing straightforward installation. Plug-and-play commissioning ensures setup is quick and simple.Q: What industries benefit most from using the LENZE SERVO DRIVE E82EV251_2C?

A: Industries such as packaging, textiles, and automated conveyor systems benefit from its high efficiency, integrated brake control, and precise vector/V/f control capabilities.Q: When is it necessary to use the integrated brake chopper feature?

A: The integrated brake chopper is crucial during rapid deceleration or emergency stops, enhancing safety by safely dissipating regenerative energy.Q: Where can I find firmware upgrades for this device?

A: Firmware upgrades are available through LENZEs official PC software, which ensures your drive stays up-to-date with the latest features and security enhancements.Q: What is the process for ordering and receiving a sample unit?

A: Simply place a purchase order with your supplier or trader. Upon confirmation, shipment and delivery will be arranged as per the agreed terms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE E82EV751_2C

Cooling Method : Air cooling (integrated fan)

Weight : Approx. 1.3 kg

Material : Industrial grade plastic and metal

Storage Temperature : 25C to +70C

Working Temperature : 10C to +55C

Application : Automation systems, packaging machines, conveyor systems

LENZE SERVO DRIVE EVF8202-E

Cooling Method : Forced Air Cooling

Weight : 1.2 kg

Material : Industrial Grade Plastic & Aluminum

Storage Temperature : 25C to +70C

Working Temperature : 10C to +55C

Application : Automation, Packaging, Conveying Systems

LENZE EVF9321 EV DRIVE

Cooling Method : Internal Fan Cooling

Weight : Approx 3 kg

Material : Industrial Grade Plastic and Metal

Storage Temperature : 25C to +70C

Working Temperature : 10C to +45C

Application : Pumps, Fans, Conveyor Systems, Industrial Automation

LENZE ESMD371L4TXA DRIVE

Cooling Method : Air cooled (integral fan)

Weight : Approx. 1.1 kg

Material : Highgrade industrial plastic housing

Storage Temperature : 25C to +70C

Working Temperature : 10C to +55C

Application : Industrial Automation, Pumps, Fans, Conveyors

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry