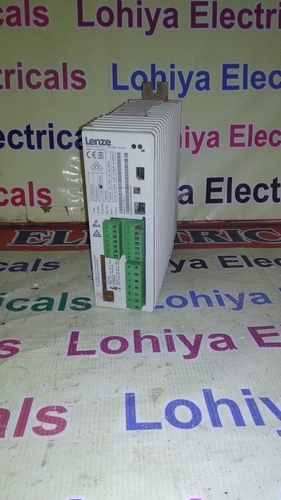

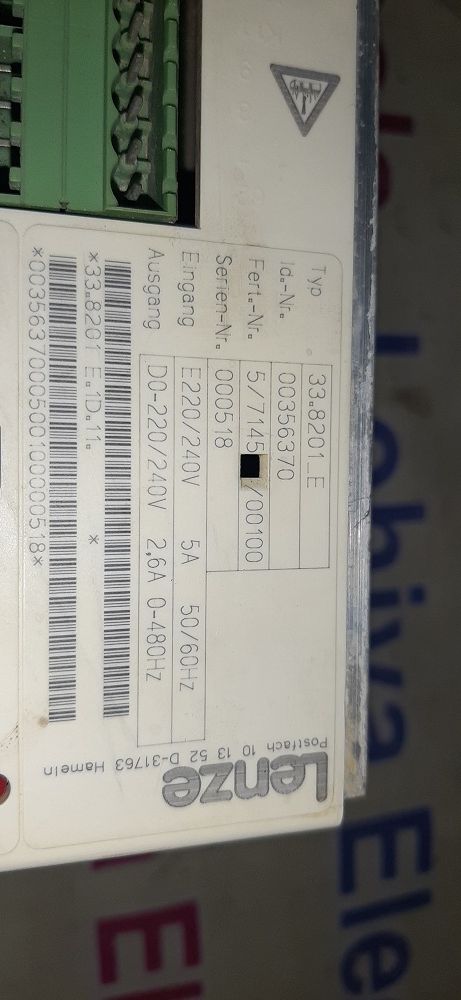

LENZE SERVO DRIVE 33.8201 E

LENZE SERVO DRIVE 33.8201 E Specification

- Power Supply

- 3 x 400V AC, 50/60 Hz

- Power Factor

- >0.95

- Working Temperature

- 0C to +55C

- Rated Current

- 5.5 A

- Phase

- Three-phase

- Operating Temperature

- 0C to +55C

- Connector Type

- Terminal Block

- Cooling Method

- Fan cooling

- Noise Level

- < 60 dB

- Rated Power

- 2.3 kW

- Output Current

- 5.5 A

- Application

- Automation, Packaging, Robotics, CNC Machines

- Current Range

- 010 A

- Features

- Dynamic braking, Integrated safety functions, Diagnostic display

- Output Type

- Three-phase AC

- Product Type

- Servo Drive

- Output Power

- 2.3 kW

- Output Frequency

- 0-600 Hz

- Input Voltage

- 3 x 400V AC

- Voltage Protection

- Overvoltage, Undervoltage protections included

- Efficiency

- Up to 96%

- Material

- Metal (Housing)

- Line Regulation

- 1%

- Storage Temperature

- -25C to +70C

- Weight

- Approx. 12 kg

- Motor Compatibility

- AC Servo Motors

- Maximum Switch Frequency

- up to 16 kHz

- Mounting Type

- Panel Mount

- Degree of Protection

- IP20

- Dimensions (H x W x D)

- 410 x 230 x 200 mm

- Position Feedback

- Resolver / Encoder interfaces

- Communication Interface

- RS232/RS485 port, CANopen compatible

- Response Time

- < 1 ms

- Brake Control

- Integrated relay for brake control

- Control Method

- Vector Control, V/f Control

- Display Type

- LED status indicators

About LENZE SERVO DRIVE 33.8201 E

Key Usage Areas and Applications

LENZE SERVO DRIVE 33.8201 E is widely used by automation engineers and system integrators in sectors such as packaging, robotics, and CNC machinery. Its specific use includes precise motion control and advanced positioning in industrial settings. With its versatile design, it serves general use in multi-axis systems and dynamic servo motor operation. This panel-mounted, three-phase AC servo drive is ideal for both standalone and integrated machine automation requirements, delivering reliable performance in demanding environments.

Certifications, Export Details & Sample Policy

LENZE SERVO DRIVE 33.8201 E is supplied and traded in compliance with relevant industrial certifications, ensuring top-drawer quality for export market needs. Stock is ready for prompt shipment from major FOB ports, expediting order completion for international clients. The supplier offers a flexible sample policy, allowing potential buyers to evaluate drive suitability before bulk procurement. Deal confidently, as high standards and prodigious reliability are consistently maintained in every unit shipped.

FAQs of LENZE SERVO DRIVE 33.8201 E:

Q: How is the LENZE SERVO DRIVE 33.8201 E typically installed in industrial facilities?

A: This servo drive is designed for panel mount installation, making integration into control cabinets or automation panels straightforward and secure for a wide range of industrial setups.Q: What are the main benefits of using Vector Control and V/f Control on this servo drive?

A: The highlighted Vector Control and V/f Control options deliver precise, responsive motor management and noteworthy positioning accuracy, ensuring prodigious performance in automation and robotic applications.Q: When should the integrated relay for brake control be utilized?

A: The integrated relay for brake control can be capitalized on during machine start-stop cycles, especially for top-drawer safety and reliable holding positions in machinery such as CNC systems and packaging lines.Q: Where do the communication options like RS232/RS485 and CANopen excel?

A: RS232/RS485 and CANopen interfaces are valuable in networked automation environments where seamless integration with PLCs, controllers, and top-tier machine networks is required.Q: What process ensures voltage protection and safe operation?

A: The drive incorporates overvoltage and undervoltage protection systems, maintaining stable and reliable operation. This safeguards equipment from electrical anomalies, ensuring long-term prodigious performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in OMRON PROFIBUS MODULE Category

LENZE SERVO DRIVE EVF9324-EVV004

Working Temperature : 0C to +40C

Power Factor : > 0.95

Power Supply : AC Mains

Product Type : Servo Drive

Output Power : 2.2 kW

Voltage Protection : Overvoltage, Undervoltage Protection

LENZE SERVO DRIVE EVS9324-ES

Working Temperature : 0C to +55C

Power Factor : >0.98

Power Supply : AC supply 340 528 V

Product Type : Servo Drive

Output Power : 5.5 kW

Voltage Protection : Integrated overvoltage and undervoltage protection

LENZE EVS9326 EK DRIVE

Working Temperature : 0C to +55C

Power Factor : >0.95

Power Supply : Three Phase 400500 V AC

Product Type : Frequency Inverter / AC Drive

Output Power : 15 kW

Voltage Protection : Integrated Overvoltage and Undervoltage Protection

LENZE SERVO DRIVE EVF8202-E

Working Temperature : 10C to +55C

Power Factor : >= 0.95

Power Supply : AC

Product Type : Servo Drive

Output Power : 0.37 kW

Voltage Protection : Overvoltage / Undervoltage Protection

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry