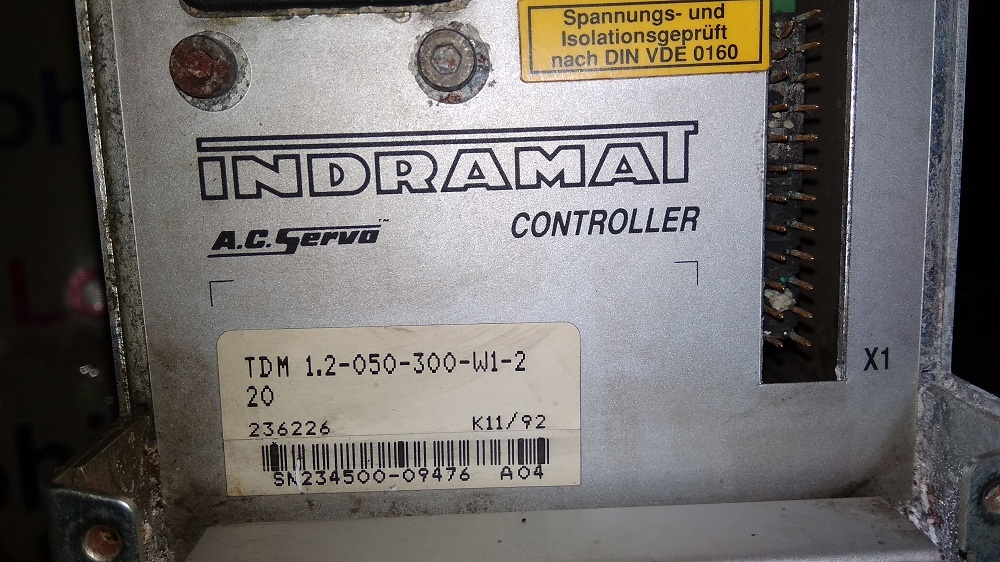

INDRAMAT SERVO DRIVE

INDRAMAT SERVO DRIVE Specification

- Features

- Short-circuit protection, Over-temperature protection, Digital display, Multiple interface support

- Operating Temperature

- 0C to 45C

- Noise Level

- <60 dB

- Output Current

- Up to 9 A

- Working Temperature

- 0C to 45C

- Current Range

- 0-9 A

- Power Supply

- AC Mains

- Cooling Method

- Forced Air Cooling

- Power Factor

- >0.95

- Output Type

- Digital and Analog

- Application

- Industrial Automation, CNC Machinery, Robotics

- Rated Power

- 3.5 kW

- Connector Type

- Screw Terminal

- Rated Current

- 9 A

- Phase

- Three Phase

- Product Type

- Servo Drive

- Output Power

- 3.5 kW

- Output Frequency

- 0-400 Hz

- Input Voltage

- 3 x 400 V AC

- Voltage Protection

- Overvoltage and undervoltage protection included

- Efficiency

- Above 90%

- Material

- Industrial grade metal housing

- Line Regulation

- 0.5%

- Storage Temperature

- -25C to +70C

- Weight

- Approx 8 kg

About INDRAMAT SERVO DRIVE

Versatile Application and Directions for INDRAMAT SERVO DRIVE

The INDRAMAT SERVO DRIVE excels in diverse environments including industrial automation, CNC machinery, and robotics. Its panel mount design allows easy integration onsite for streamlined operations. Follow proper wiring using screw terminal connectors as indicated in the installation guide, and ensure ambient conditions align with specified humidity and temperature for optimal performance. This drive is noteworthy for its role in enhancing precision, productivity, and system efficiency across multiple sectors, making it a must-have for advanced automation platforms.

Reliable Supply, Delivery Time, and Market Reach

We guarantee timely delivery of the INDRAMAT SERVO DRIVE with a robust supply ability, ensuring you access the lowest price available. With a strong presence in the domestic Indian market, our distribution network efficiently supports both export markets and local demand. Expect transparent lead times and responsive customer support. Whether you require single or bulk orders, our seamless logistics and competitive pricing structure provide unmatched value for all your automation requirements.

FAQs of INDRAMAT SERVO DRIVE:

Q: How does the INDRAMAT SERVO DRIVE benefit industrial automation?

A: The INDRAMAT SERVO DRIVE enhances automation by providing precise control, rapid response times (<1 ms), and high operational efficiency, making it ideal for applications like CNC machinery and robotics.Q: What applications can utilize this servo drive?

A: This servo drive is suited for industrial automation, CNC machinery, and robotics, where precise motion control and reliable performance are essential requirements.Q: When should you consider using regenerative braking?

A: Regenerative braking should be used when rapid deceleration of the motor is required, improving energy efficiency and reducing heat generation during demanding operations.Q: Where is the best mounting location for the INDRAMAT SERVO DRIVE?

A: It is designed for panel mounting in environments that meet temperature (0C to 45C) and humidity (5%-95% non-condensing) requirements, ensuring longevity and optimal performance.Q: What process should be followed for installation?

A: The drive should be installed on a panel using the screw terminal connectors, with careful attention to wiring and grounding. Follow the manufacturers installation guide for safety and accuracy.Q: How do the protective features contribute to device longevity?

A: Integrated overvoltage, undervoltage, short-circuit, and over-temperature protections safeguard the device, extending its service life and promoting safe, uninterrupted operation for at least 10 years under standard conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in INDRAMAT Used HMI SERVO DRIVE Category

INDRAMAT SERVO DRIVE

Product Type : Servo Drive

Cooling Method : Forced Air Cooling

Features : Short Circuit Protection, Overload Protection, Fast Response, Compact Design

Material : Industrial Grade Alloy

Connector Type : Screw Terminal

Application : Industrial Automation, CNC Machines, Robotics

INDRAMAT SERVO DRIVE

Product Type : Servo Drive

Cooling Method : Integrated fan cooling

Features : Shortcircuit protection, compact design, highspeed response

Material : Industrialgrade metal enclosure

Connector Type : Screw terminal

Application : Industrial automation, CNC machinery, robotics

INDRAMAT DDC01.2- (2)

Product Type : Drive Controller

Cooling Method : Aircooled

Features : Programmable Compact design

Material : Metal casing

Connector Type : Standard

Application : Industrial Automation

Indramat Rank 209-011-4/20

Product Type : Indramat Rank 2090114/20 Servo Drive Controller

Cooling Method : Forced air cooling

Features : High reliability, compact design, over/under voltage protection, short circuit protection, dynamic braking

Material : Industrial metal enclosure

Connector Type : Terminal block

Application : Servo motor control, automation systems, CNC machinery

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry