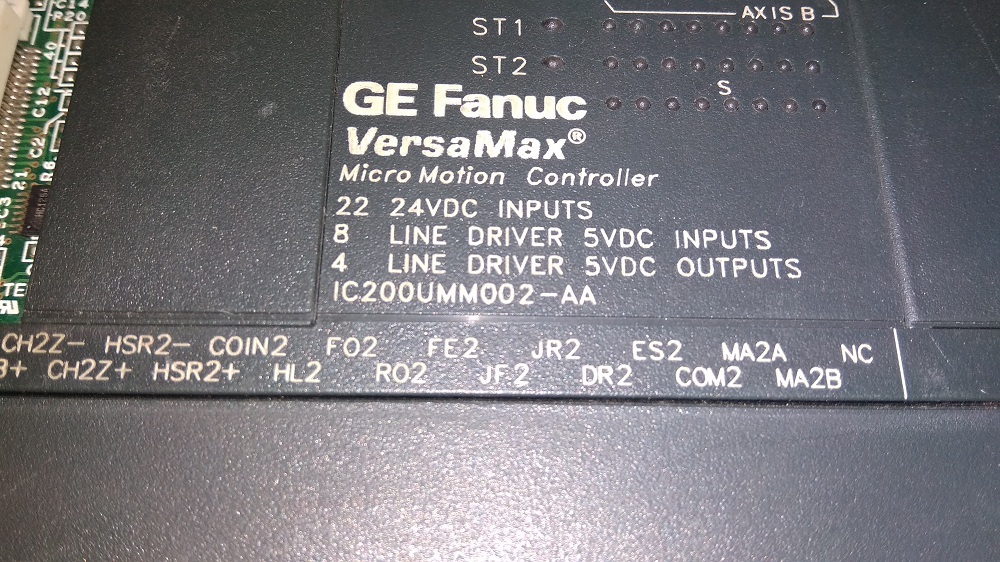

GE FANUC PLC

GE FANUC PLC Specification

- Cooling Method

- Natural air cooling

- Features

- Modular design, Expandable I/O, Integrated diagnostics, Easy programming

- Output Type

- Relay and Transistor outputs

- Output Current

- Max 0.75A per output module

- Power Supply

- Integrated or external (module dependent)

- Working Temperature

- 0C to +60C

- Connector Type

- Screw terminal or pluggable connectors

- Application

- Industrial Automation, Process Control, Machinery

- Power Factor

- >0.93

- Phase

- Single Phase

- Rated Current

- 0.75A (per output)

- Rated Power

- Depends on module, typically 18W

- Noise Level

- <55 dB

- Current Range

- 0.3A to 0.75A (module dependent)

- Operating Temperature

- 0C to +60C

- Product Type

- Programmable Logic Controller (PLC)

- Output Power

- 24V DC, 0.75A (typical per output module)

- Output Frequency

- 50/60Hz

- Input Voltage

- 120-240V AC (typical)

- Voltage Protection

- Over-voltage and Under-voltage protection included

- Efficiency

- Up to 85% (Power Supply)

- Material

- High-grade industrial plastic and metal casing

- Line Regulation

- <0.5%

- Storage Temperature

- -40C to +85C

- Weight

- Approx. 820g

About GE FANUC PLC

Versatile Applications and Outstanding Features of GE FANUC PLC

GE FANUC PLCs are designed for versatile industrial automation, process control, and high-demand machinery environments. Their best-in-class modular design ensures effortless expandability and efficient usage, with up to 12 modules and a powerful 4K-step memory (model dependent). Users benefit from optional analog I/O modules, over-voltage and under-voltage protection, and LED status indicators for superior operational reliability. Featuring both relay and transistor outputs, these PLCs are an exceptional solution for advanced automation tasks in manufacturing, utilities, and machine control.

Sample Policy, Supply Chain, and Domestic Supply Ability of GE FANUC PLC

Interested buyers may request sample units to minimize initial expenditure before bulk order processing. As a trusted supplier, we maintain a robust supply chain, ensuring timely delivery and efficient order fulfillment. Our streamlined distribution network provides dependable supply across the main domestic market, catering to process industries, automation installers, and OEMs. Customers can expect responsive support and consistent availability, making GE FANUC PLC the intelligent choice for cost-effective automation solutions.

FAQs of GE FANUC PLC:

Q: How does the expandable architecture of the GE FANUC PLC benefit industrial applications?

A: By allowing the connection of up to 812 modules, the expandable architecture ensures scalability, accommodating growing system requirements and evolving production needs without replacing the main PLC.Q: What are the main usage areas where GE FANUC PLCs provide optimal performance?

A: GE FANUC PLCs deliver optimal performance in industrial automation, process control, and machinery management, supporting manufacturing plants, utilities, and custom equipment setups requiring reliable, flexible, and efficient control solutions.Q: When should you choose optional analog I/O modules for your GE FANUC PLC?

A: Optional analog I/O modules are ideal when your application needs to monitor or control variables like temperature, pressure, or speed, enhancing versatility and integrating seamlessly with your process requirements.Q: Where can you mount GE FANUC PLCs in an industrial environment?

A: GE FANUC PLCs are designed for both DIN rail and panel mounting, offering flexibility in installation and making them suitable for a wide range of control cabinets and machinery layouts.Q: What is the process for ordering and supplying GE FANUC PLCs domestically?

A: Buyers can request samples to evaluate suitability before placing larger orders. Upon order confirmation, our streamlined process ensures cost-effective expenditure, quick order processing, and prompt supply through established domestic distribution networks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GE FANUC Used PLC MODULE CPU Category

GE FANUC MODULE IC200PWR002D

Cooling Method : Natural Cooling

Weight : Approximately 150g

Features : Compact size Reliable power supply Easy installation

Working Temperature : 20C to 60C

Connector Type : Screw Type Connector

Application : Industrial Automation

GE FANUC VERSAMAX MODULE IC200MDL241B

Cooling Method : Natural convection

Weight : Approx. 130 grams

Features : LED status indication, removable terminal block, compact design

Working Temperature : 0C to 60C

Connector Type : Removable terminal block

Application : Factory automation, machine control, process control

GE FANUC INPUT MODULE

Cooling Method : Passive / Natural Air Cooling

Weight : Approx. 120g

Features : LED Status Indicators, DIN Rail Mounting, Easy Installation

Working Temperature : 0C to 60C

Connector Type : Screw Terminal

Application : Industrial Automation, PLC Systems

GE FANUC VERSAMAX ANALOG OUTPUT MODULE

Cooling Method : Natural air convection

Weight : Approx. 150 g

Features : Compact design, high precision, hotswappable, easy installation

Working Temperature : 0C to 60C

Connector Type : Removable terminal block

Application : Industrial Automation, Process Control

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry