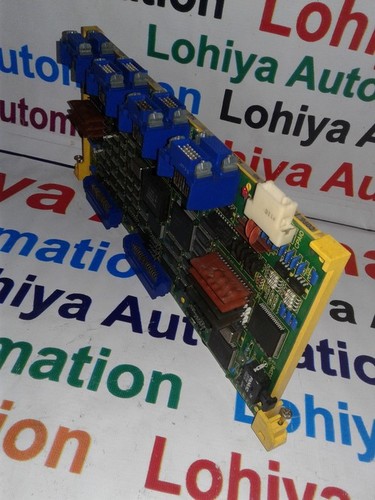

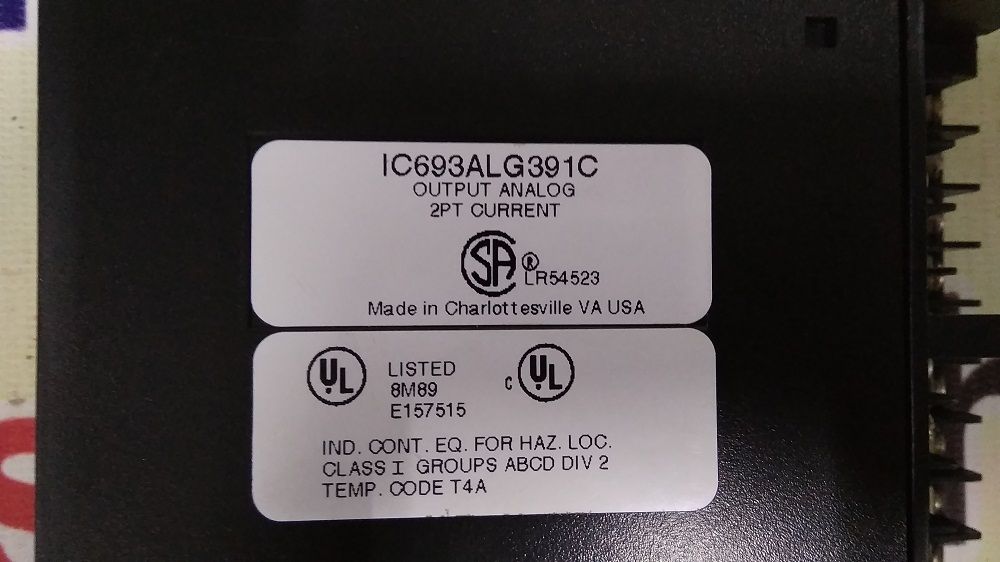

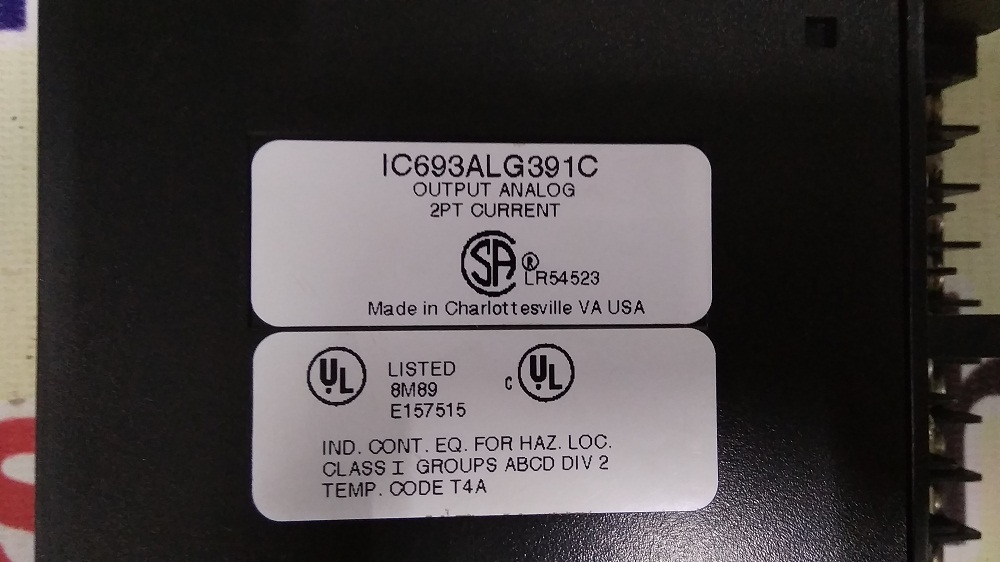

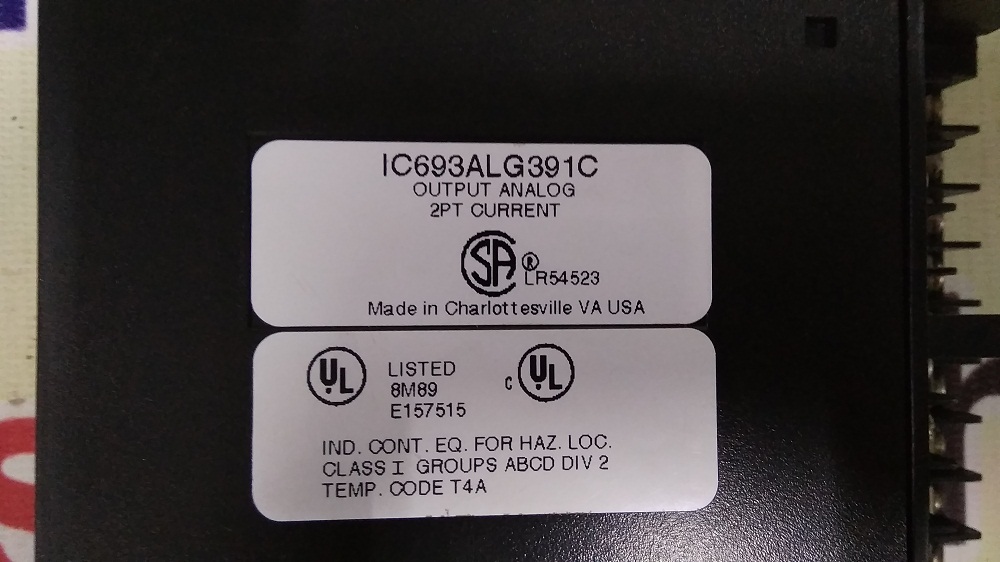

GE FANUC OUTPUT ANALOG MODULE

GE FANUC OUTPUT ANALOG MODULE Specification

- Current Range

- 020 mA / 420 mA

- Power Supply

- External 24 VDC

- Noise Level

- <1% of span

- Output Current

- 020 mA or 420 mA (configurable)

- Operating Temperature

- 0C to 60C

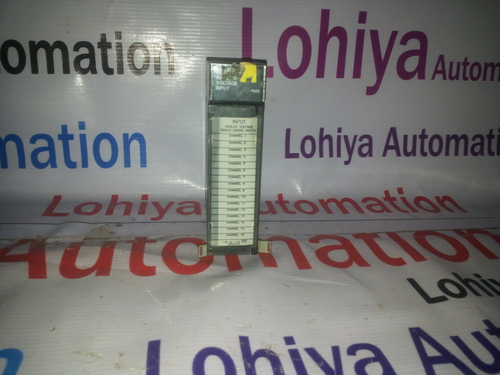

- Connector Type

- Removable Terminal Block

- Features

- Hot Swap, Easy Configuration, LED Indicator

- Application

- Industrial Automation and Process Control

- Rated Current

- 20 mA max per channel

- Output Type

- Analog (Current/Voltage)

- Working Temperature

- 0C to 60C

- Phase

- Single Phase

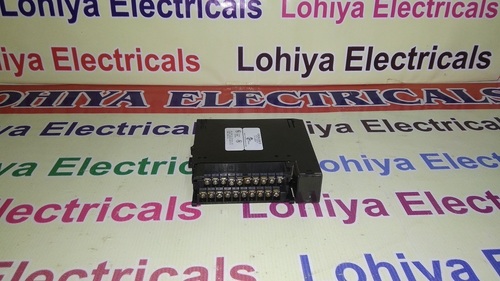

- Cooling Method

- Natural Convection

- Product Type

- Analog Output Module

- Input Voltage

- 24 VDC

- Voltage Protection

- Overvoltage, Reverse Polarity Protection

- Material

- Industrial Grade Plastic & Metal

- Line Regulation

- 0.05% of full scale

- Storage Temperature

- -40C to 85C

- Weight

- Approx. 200 g

- Compatibility

- Series 90-30, 90-70 PLCs

- Isolation

- Channel-to-Backplane Isolation, 1000 VAC

- Response Time

- 1 ms typical

- Mounting Type

- DIN Rail Mount

- Dimensions

- 120 x 35 x 85 mm (H x W x D)

- Number of Channels

- 2, 4, or 8 channels (depending on model)

- Signal Resolution

- 12-bit or 16-bit (model dependent)

About GE FANUC OUTPUT ANALOG MODULE

Superior Features and Plant Advantages

The GE FANUC Output Analog Module stands out with features like hot swapping, easy configuration, and real-time LED indicators. Crafted from industrial-grade plastic and metal, it ensures durability in challenging environments. Its natural convection cooling and noise levels under 1% boost operational efficiency for process control or automation systems. The adaptable current output suits varied plant requirements, making it the preferred choice for robust, long-term industrial applications.

Domestic Market Reach and Secure Transactions

With a wide main domestic market network, the GE FANUC Output Analog Module is available to suppliers and traders across the region. Seamless payment terms accommodate business needs, while a transparent sample policy assists in informed decision-making. Customers benefit from dependable transportation, timely delivery estimates, and secure shipping, ensuring each module reaches its destination safely and efficientlybacked by trusted supplier reliability.

FAQs of GE FANUC OUTPUT ANALOG MODULE:

Q: How is the GE FANUC Output Analog Module installed within automation systems?

A: The module is designed for DIN rail mounting, streamlining integration into Series 90-30 or 90-70 PLCs and ensuring easy in-panel setup during plant upgrades or new installations.Q: What advantages does the channel-to-backplane isolation provide?

A: Channel-to-backplane isolation (rated at 1000 VAC) protects your system from voltage spikes and electrical interference, enhancing operational reliability and equipment lifespan.Q: Where can I utilise the special offer for this top-tier analog module?

A: You can access special rates and savings through authorized domestic market suppliers and traders, ensuring competitive pricing and genuine products.Q: What are the compatible input voltages and current ranges for this module?

A: It operates on a 24 VDC external power supply and offers configurable output currentseither 020 mA or 420 mA, depending on your process requirements.Q: How does the sample policy and shipping process work?

A: Potential buyers can request a sample based on the suppliers sample policy. After securing an order, modules are transported via secure shipping channels, with delivery estimates provided to ensure timely and safe arrival.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GE FANUC Used PLC MODULE CPU Category

FANUC SYSTEMS CARD AI6B-2200-080

Operating Temperature : 0C to 50C

Material : PCB and Plastic

Cooling Method : None (Passive)

Working Temperature : 0C to 50C

Features : Durable Highspeed processing

Application : Industrial Automation

GE FANUC OUTPUT MODULE

Operating Temperature : 0C to +60C

Material : Industrial Grade Plastic and Metal

Cooling Method : Natural Air Cooling

Working Temperature : 0C to +60C

Features : DIN Rail Mountable, Removable Terminal Block, LED Status Indicators

Application : Industrial Automation Systems

GE FANUC VERSAMAX MODULE IC200MDL750B

Operating Temperature : 0C to +60C

Material : Industrial Grade Plastic Housing

Cooling Method : Natural convection

Working Temperature : 0C to +60C

Features : LED status indicators, Removable terminal block, Compact size, RoHS compliant

Application : Industrial Automation, PLC Systems

16-Channel GE Fanuc IC693ALG222C Analog Voltage Input Module

Operating Temperature : 0C to 60C (32F to 140F)

Material : Industrialgrade plastic and metal

Cooling Method : Passive Cooling

Working Temperature : 0C to 60C (32F to 140F)

Features : 16channel analog voltage input; high accuracy; compatibility with GE Fanuc Series 9030 PLCs

Application : Industrial Automation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry