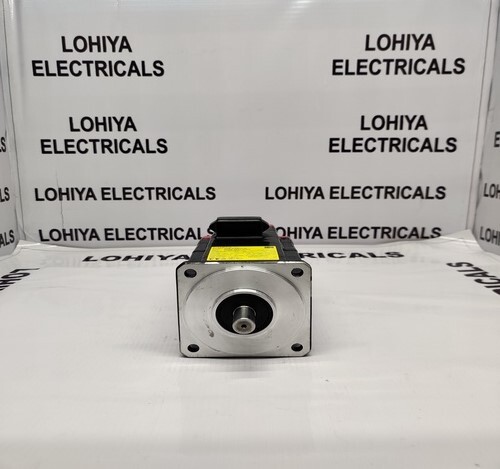

FANUC SERVO MOTOR

FANUC SERVO MOTOR Specification

- Base Material

- Aluminum Alloy

- Connectivity Type

- Servo Connector

- Components

- Encoder, Shaft, Housing, Connectors

- Rated Current

- 5.9A

- Operating Voltage

- 200V AC

- Protection Class

- Class F

- Thickness

- Standard

- Way

- Single

- Current Rating

- 5-10A

- Cover Material

- Aluminum

- Rated Operation Voltage

- 200-230V AC

- Features

- High Torque, Precision Feedback, Low Noise

- Cooling System

- Natural Air Cooling

- Rated Insulation Voltage

- 250V

- Control System

- Digital Servo Drive

- Protection Level

- IP65

- Product Type

- Servo Motor

- Material

- High-Grade Steel and Aluminum Alloy

- Surface Finish

- Matte Powder Coated

- Standard

- FANUC Standard

- Surface Color

- Black and Yellow

- Rated Voltage

- 200V AC

- Frequency (MHz)

- 50/60 Hz

- Maximum Output Current

- 10A

- Dimension (L*W*H)

- 210 mm x 90 mm x 130 mm

- Application

- Industrial Automation, CNC Machines

- IP Rating

- IP65

About FANUC SERVO MOTOR

The FANUC SERVO MOTOR A06B Series is a popular choice for procurements in advanced automation settings, acclaimed for its peerless reliability and resplendent design. With a spectacular torque rating of 1.27 Nm and a robust speed of 3000 RPM, this servo motor features an incremental magnetic encoder and a sturdy flange mount. Its high-grade steel and aluminum alloy construction ensures a matte powder-coated finish and long-term durability. Integrated with an electromagnetic brake, it excels in CNC and industrial automation with impeccable vibration resistance and extended operational life.

Optimized Plant Application and Usage Directions

FANUC SERVO MOTOR is meticulously crafted for industrial automation and CNC machine operations in various plant environments. To achieve optimal results, mount the motor using the flange design, connect via the servo connector, and integrate with FANUC alpha series drives. Its specific usage focuses on delivering precise motion control and high-torque applications, ensuring smooth, efficient workflows in production lines and robotic setups. Always operate within 0C to 40C for the finest performance outcomes.

Delivery, Expenditure, and Certification Details

Procurement and delivery of the FANUC SERVO MOTOR are organized for swift supply, supporting advance purchase to minimize plant downtime. Sample units are available for preliminary evaluation, streamlining expenditure decisions for large-scale orders. The motor complies with leading quality standards and certifications, reinforcing confidence in every batch delivered. Expect prompt delivery schedules and professional assistance for all trade requirements, ensuring your industrial investments are certified for performance and safety.

Optimized Plant Application and Usage Directions

FANUC SERVO MOTOR is meticulously crafted for industrial automation and CNC machine operations in various plant environments. To achieve optimal results, mount the motor using the flange design, connect via the servo connector, and integrate with FANUC alpha series drives. Its specific usage focuses on delivering precise motion control and high-torque applications, ensuring smooth, efficient workflows in production lines and robotic setups. Always operate within 0C to 40C for the finest performance outcomes.

Delivery, Expenditure, and Certification Details

Procurement and delivery of the FANUC SERVO MOTOR are organized for swift supply, supporting advance purchase to minimize plant downtime. Sample units are available for preliminary evaluation, streamlining expenditure decisions for large-scale orders. The motor complies with leading quality standards and certifications, reinforcing confidence in every batch delivered. Expect prompt delivery schedules and professional assistance for all trade requirements, ensuring your industrial investments are certified for performance and safety.

FAQs of FANUC SERVO MOTOR:

Q: How can I benefit from using the FANUC SERVO MOTOR in my industrial automation systems?

A: Integrating the FANUC SERVO MOTOR offers reliable motion control, high torque, and precision feedback, resulting in enhanced production efficiency and reduced equipment downtime in automation and CNC applications.Q: What is the process to procure a FANUC SERVO MOTOR for our facility?

A: You can initiate advance purchase with your supplier or trader in India, who will guide you through the procurement process, sample availability, certification verification, and finalize delivery timelines for quick supply.Q: When should the motor be installed for peak performance?

A: Install the motor during scheduled downtime or system upgrades, ensuring ambient temperatures are between 0C to 40C and correct drive compatibility with FANUC Alpha Series Servo Drives for seamless operation.Q: Where can the FANUC SERVO MOTOR be ideally applied?

A: This motor is engineered for integration in CNC machines, robotics, and various industrial automation setups that demand high precision and durability within a controlled environment.Q: What certifications and standards does the FANUC SERVO MOTOR comply with?

A: The A06B Series meets FANUC standards, vibration resistance standards like JIS B 3502, and holds a protection level of IP65, ensuring reliability, safety, and robust performance.Q: How does the integrated electromagnetic brake enhance motor usage?

A: The integrated electromagnetic brake promotes safety by securely holding loads during power interruptions and provides accurate stopping capabilities in critical automation processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FANUC SERVO MOTOR Category

FANUC A06B-0127-B077 AC SERVO MOTOR

Minimum Order Quantity : 1 Piece

Product Type : Other, AC Servo Motor

Protection Level : IP65

Control System : Closed Loop

Material : Metal

FANUC A06B-2063-B403 AC SERVO MOTOR

Minimum Order Quantity : 1 Piece

Product Type : Other, AC Servo Motor

Protection Level : IP67

Control System : Pulsecontrolled encoder

Material : Other, Highstrength alloy steel

FANUC A06B-0202-B605S000 AC SERVO MOTOR

Product Type : Other, AC Servo Motor

Protection Level : IP65

Control System : Digital Servo Control

Material : Other, Metal Alloy

FANUC A06B-0371-B070 AC SERVO MOTOR

Product Type : Other, AC Servo Motor

Protection Level : IP65

Control System : Digital Servo Control

Material : Other, Highgrade aluminum alloy

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry